Creep and Crimp of fiber

Share via:

-

Save

Md Sohanur Rahman Sobuj

-

Save

-

Save

-

Save

Latest posts by Md Sohanur Rahman Sobuj (see all)

- Thermal Properties of Polymers - April 26, 2019

- Frictional Properties - September 15, 2018

- Torsional Properties of Textile Materials - August 30, 2018

Creep and Crimp of fiber

Creep and Stress Relaxation

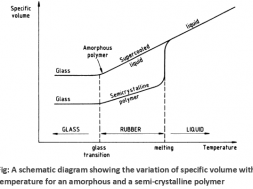

Time dependency behavior is one of the main characteristics of any viscoelastic materials. Some materials such as polymers exhibit a time dependent behavior.

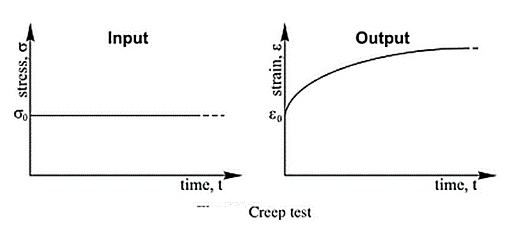

The slow continuous deformation of a viscoelastic material under a constant load is called creep and the magnitude of the creep depends on the properties of viscoelastic material.

The other aspect of the time dependent behavior of a viscoelastic material is stress relaxation. This means that the stress will be reduced or will relax under a constant deformation. This behavior is illustrated below:

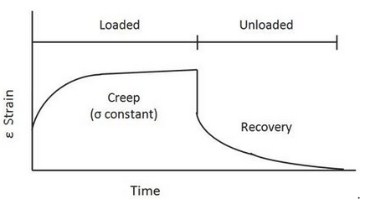

Creep recovery: Creep is a reversible phenomenon. Once the load is removed, the original shape (or length in this case) is recovered. This is called creep recovery. Recovery is not instantaneous and is also a function of time.

Creep rate: The slope between creep stain-time curve is called creep rate.

Different creep stages: When the temperature is constant, viscoelastic creep is typically simplified as primary, secondary and tertiary creep, followed by rupture.

⨳ Instantaneous deformation: Length is increasing rapidly without time difference.

⨳ Primary creep: creep rate decreases with time due to strain hardening.

⨳ Secondary creep: Creep rate is constant due to simultaneous strain hardening and recovery process.

⨳ Tertiary creep: Creep rate increases with time leading to necking and fracture.

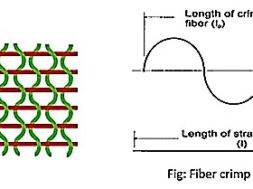

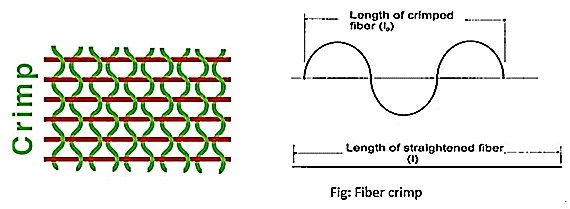

Fiber Crimp: Crimp is a term to describe the waviness of a fiber. We can also describe this in terms of the force or energy required to uncrimp a fiber. It’s expressed in percentage.

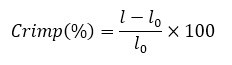

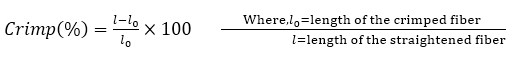

A crimped fiber placed on a flat plane is l0 and the length of the same fiber when the crimp is removed by applying a tension is l, then the crimp is given by …

Besides this scientific representation of crimp, sometimes crimp is also specified by the number of crimps per unit length of extended or straightened fiber

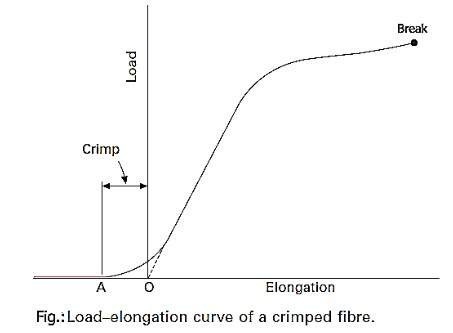

Load-elongation curve of a crimped fiber

If a crimped fiber is inserted into the crimp tester without any initial tension, the load-elongation curve will have the form shown in Fig.

The origin of the curve put at A, where it diverges from the zero line. But this point is difficult to locate precisely. A better procedure is to put the origin at O, the extrapolated point corresponding to a hypothetical straight fiber. The crimp is given by AO and expressed in percentage;

(4321)

-

Save

Md Sohanur Rahman Sobuj

-

Save

-

Save

-

Save

Latest posts by Md Sohanur Rahman Sobuj (see all)

- Thermal Properties of Polymers - April 26, 2019

- Frictional Properties - September 15, 2018

- Torsional Properties of Textile Materials - August 30, 2018

-

Save

Share via: