Maintenance Schedule Of Cylinder Dryer

65

0

Maintenance Schedule Of Cylinder Dryer

Objects:

- To know the gearing mechanism.

- To know the different types of maintenance.

- To inspect different controlling points.

Main parts:

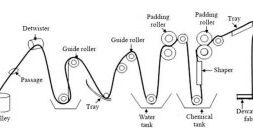

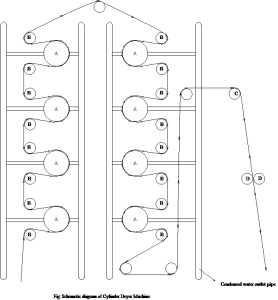

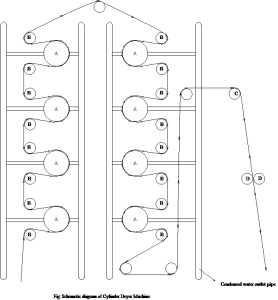

- Hollow cylinder

- Guide roller

- Free roller

- Pin roller

- Swimming roller

Utilities:

- Electricity

- Water

- Steam

Maintenance:

- Guide roller: Here we have to look over the movement of guide roller. We have to provide the steady of guide roller or without movement of guide roller.

- Free roller movement: Free roller should be move freely as the path of material. So we always look over of the free movement of free roller.

- Proper gearing: It is very important that the lack of proper gearing will hamper the correct function. So we have to maintain the gearing properly.

- Motor revolution: For proper speed the correct rpm of motor should be check as maintenance.

- Proper heating: We have to confirm of even & proper heating of every cylinder as the action of drying.

- Let out of condensed water: After drying action simultaneous the steam can be condensed to water & should be let out by the exhaust pipe. So it should be maintained properly.

Uses of cylinder dryer:

- To dry the fabric

- To remove the remaining excess water from fabric.

Maintenance schedule:

|

Sl no. |

Name of the maintenance work |

Time interval |

|

01. |

Steam pressure regulator checking |

Every hour |

|

02. |

Cleaning of the cylinders |

Every batch unloaded |

|

03. |

Checking the water pipe |

Everyday |

|

04. |

Checking the motor and electric connection |

Weekly |

|

05. |

Greasing and oiling in roller bearings and gears |

Weekly |

|

06. |

Cleaning the steam inlet and outlet pipe |

Weekly |

|

07. |

Checking the flow of water |

Every hour |

|

08. |

Checking the efficiency of fabric tensiobner |

Every hour |

|

09. |

Checking the inlet and outlet valves |

Everyday |

Conclusion:

maintenance is very important work for any machine. By this, the longer life & production capacity will increase. So this experiment will surely be helpful for our future profession life.

You May Look :

(65)