Mastering Waterproof Performance: A Deep Dive into Fabric Waterproof Testers and Hydrostatic Pressure Testers

In today’s textile industry, the demand for high-performance waterproof fabrics continues to grow, driven by sectors ranging from outdoor gear and protective clothing to military applications and smart textiles. Accurate waterproof testing is essential for ensuring product quality and consumer satisfaction. Among the most critical tools for this purpose are the Fabric Waterproof Tester and the Hydrostatic Pressure Tester. These instruments play a pivotal role in determining how well a fabric resists water penetration under various conditions.

This article explores the fundamentals, standards, testing procedures, and equipment used for hydrostatic pressure and waterproof testing of fabrics. Whether you’re a textile manufacturer, lab technician, or R&D specialist, understanding how these testers work will help you ensure compliance with quality and performance standards.

Understanding Waterproof Fabric Testing

Waterproof fabric testing evaluates the material’s ability to resist water penetration. This is especially crucial for products like rainwear, tents, car covers, upholstery, and sportswear.

Two main types of fabric are tested:

- Water-resistant fabrics: These resist water to some extent but are not completely impermeable.

- Waterproof fabrics: These prevent any water from passing through, even under pressure.

To quantify and certify waterproof performance, Hydrostatic Head Testing Equipment is used to apply controlled pressure to a fabric sample and measure the amount of water it resists before leakage.

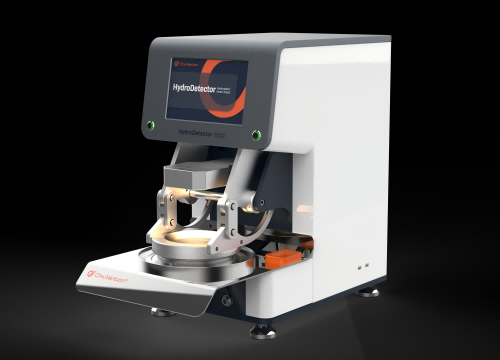

What Is a Fabric Waterproof Tester?

A Fabric Waterproof Tester is a precision instrument designed to measure the water penetration resistance of fabric samples. It simulates real-world scenarios like rain or standing water pressure. Depending on the type, the tester can mimic vertical rainfall or use pressure chambers to gauge how much hydrostatic pressure a fabric can withstand before water seeps through.

Key Features:

- Stainless steel water tank

- Transparent specimen clamping plate

- Digital or analog pressure display

- Programmable test parameters

- Safety overflow controls

What Is a Hydrostatic Pressure Tester?

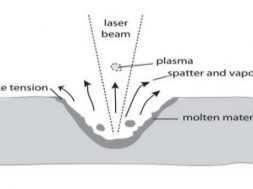

The Hydrostatic Pressure Tester is a specialized device that measures the hydrostatic head (in mm or mbar) at which water penetrates the fabric. It is often used to test waterproof membranes, coated textiles, and laminated fabrics.

Test Procedure:

- The fabric sample is securely clamped in a test head.

- Water pressure is gradually increased beneath the fabric.

- The pressure at which the first water droplets appear on the upper surface is recorded.

- This pressure value is referred to as the hydrostatic head, and it is a direct indication of the fabric’s waterproof performance.

Industry Standards for Waterproof and Hydrostatic Testing

To ensure consistency, several international standards dictate how waterproof testing should be conducted. Common standards include:

AATCC 127: Measures water resistance via hydrostatic pressure.

ISO 811: Specifies a method for determining resistance to water penetration.

EN 20811: European standard similar to ISO 811.

ASTM D751: Specifies methods for coated fabrics.

Using equipment that complies with these standards is crucial for accurate and credible results.

Choosing the Right Hydrostatic Head Testing Equipment

When selecting a Hydrostatic Pressure Tester, consider the following factors:

1. Pressure Range & Accuracy : Ensure the tester can accommodate your required testing range (typically 0 to 5000 mm or higher) with high precision.

2. Automation & Control : Advanced models offer programmable control, automatic clamping, and real-time data logging. These features enhance repeatability and efficiency.

3. Sample Size Flexibility : A tester that supports various sample sizes can handle multiple fabric types without needing different machines.

4. Compliance with Standards : Choose equipment that supports ISO 811, AATCC 127, and other relevant standards.

5. Maintenance and Calibration : Reliable equipment should include easy access for cleaning and standard calibration procedures.

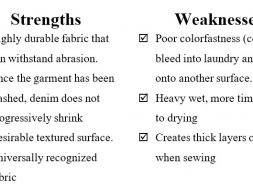

Benefits of Using a Fabric Waterproof Tester

Using a reliable Fabric Waterproof Tester provides multiple advantages:

- Quality Assurance: Ensures products meet waterproof standards before shipment.

- Product Development: Assists R&D teams in evaluating new coatings and laminates.

- Brand Reputation: Demonstrates commitment to performance and durability.

- Customer Satisfaction: Delivers waterproof products that match consumer expectations.

Applications Across Industries

Hydrostatic pressure and waterproof testing are not limited to outdoor clothing. Key sectors include:

- Medical textiles: For surgical gowns and PPE.

- Military and tactical gear: High-spec waterproofing is critical.

- Automotive interiors: Seat covers and headliners must resist moisture.

- Furniture & upholstery: Waterproof features are essential for commercial use.

Emerging Trends in Waterproof Testing

1. Digital Integration : Modern testers now include digital interfaces, real-time graphing, and USB/ethernet connectivity for lab integration.

2. Sustainability Focus : Eco-friendly waterproofing materials require precise performance verification, increasing demand for advanced testers.

3. AI & Machine Learning : AI is being integrated for predictive analysis and automated defect detection in testing procedures.

4. Compact Testers for On-site QC : Portable versions of Hydrostatic Head Testing Equipment are being developed for rapid quality checks at production sites.

How to Interpret Hydrostatic Test Results

Results are typically recorded as the pressure (in mm or mbar) at which water penetrates the fabric. Higher numbers indicate better waterproof performance.

For example:

- < 1000 mm: Low water resistance

- 1000–5000 mm: Moderate resistance (suitable for rain jackets)

- 5000 mm: High resistance (ideal for tents and performance gear)

Testers also allow multiple samples to be tested to assess consistency.

Conclusion

Whether you are manufacturing high-performance rainwear, military fabrics, or protective equipment, reliable waterproof testing is essential. By investing in advanced Fabric Waterproof Testers and Hydrostatic Pressure Testers, and ensuring adherence to international standards, manufacturers can guarantee durability, consumer satisfaction, and regulatory compliance.

Leveraging modern Hydrostatic Head Testing Equipment gives you the accuracy and repeatability needed in today’s competitive textile industry. As consumer expectations and regulatory requirements evolve, only precise and consistent waterproof testing will keep your products—and your brand reputation—secure.

For more information on textile testing methods/standards or textile testing machines,

Contact Details:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@tes.hk

(215)