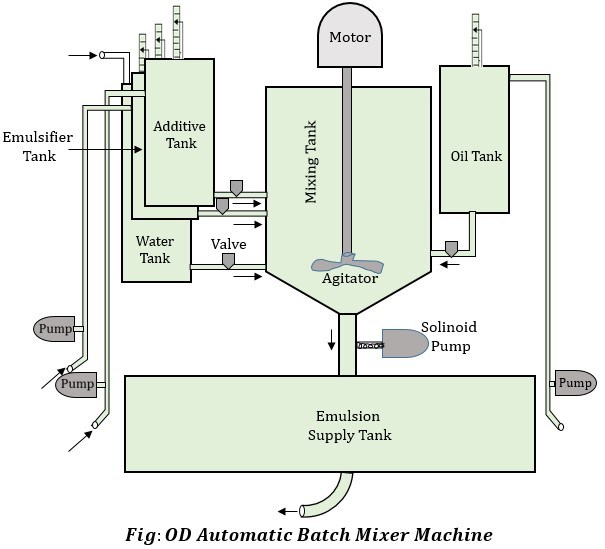

OD Automatic Batch Mixer Machine

Experiment Name: Study on the OD Automatic Batch mixer machine.

Introduction: Jute fibre is consists of lignin, so it is hard and brittle. Easily breaks down due to abrasion and mechanical treatment. To make it soft and easy a mixture of some lubricating agent is used.

The mixture of these elements is called emulsion.

- Oil → 20 – 25%

- Water → 70- 74.5%

- Emulsifier → 5% – 1.5%

OD Automatic Batch Mixer machine is a simple automatic machine for producing batching emulsion for jute.

Objectives:

To produce emulsion mixing oil and water.

To keep the proper ratio of oil and water.

To know about different parts of the machine.

To reach the emulsion to softener or spreader machine.

Emulsion is produced in such a way for which emulsion can be kept for 24 hours.

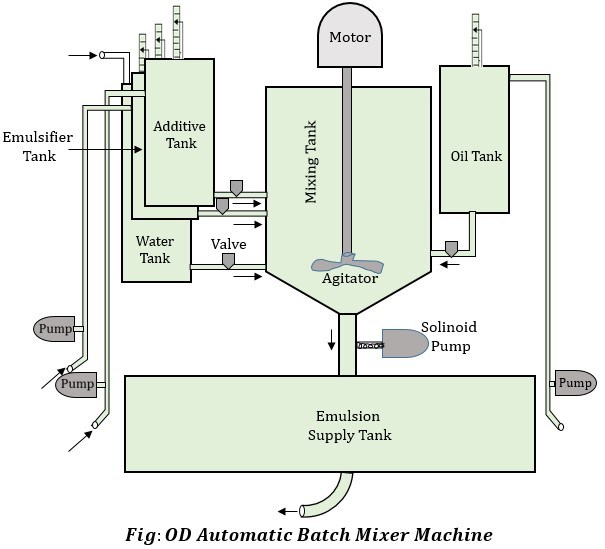

Main Parts of the machine:

Motor & Motor shaft: A motor runs the machine and shaft is attached with it.

Mixing tank: Every tank has joined pipe with this tank. Here the raw materials get mixed as a result emulsion is produced.

Emulsifier tanks: Water emulsifier is another raw material for this machine. Licapot is used as emulsifier.

Water tank: Water tank is also important parts that supply water.

Additive tanks: Additive is one of the raw materials in this machine. Urea is used as additive. It prevents decomposition.

Oil tank: Oil is the least raw materials for this machine.

Reserve or Emulsion supply tank: Emulsion is stored in this tank and supplier to softener or spreader m/c when needed.

Pump: Pump is used to control the materials amount.

Valve: There are some valves in the machine. It is used to control the flow of raw materials to mixing tank. This valves are called solenoid valves.

Scale: There are three scales on top of this tank. There are used as indicator.

Pressure gauge meter: It measures the required pressure for the process.

Procedure of emulsion preparation

- First emulsifier and equal quantity of mineral oil are place in the mixing tank and mixed until a

jelly like substance is formed.

- Then the remaining oil is added and slowly heated and mixed for 35 minutes

- Then required amount of water and additive is add and mixed for about 20 minutes until required form is achieved.

- After all the ingredients are added, the agitator on paddle starts to notate at a high rpm when emulsification is complete, the mixture is then pumped to supply tank.

- After that the emulsion is transferred to the reserve tank and kept there for 20 minutes.

- Then it is transferred to the softener or spreader machines.

Advantages:

It is automatic batch mixer machine

Ingredients are automatically measured

Agitation is vinous

Emulsion requires less time

High productivity

Disadvantages:

If controlling points are not controlled points are not controlled properly there may be huge problem.

Precaution:

Recipe should be maintained

Pressure gauge must chacked.

Conclusion:

It is the important and first machine in the jute spinning lab. It is necessary to batching the jute for the next carding process. So, study of this machine is very important for us.

(2916)