Calendering | Factors Effecting Calendering | Calendering Machine Construction

Calendering | Factors Effecting Calendering | Calendering Machine Construction

Calendering

With the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. This simultaneous action is called calendering.

Calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or rollers. The rotation speed and pressure of the heated drum may be varied according to the need.

There are different types of textile finishes. Among them calendaring is a mechanical finishing process.We can definitely beautify our fabric by calendaring.

The effect of calendering is achieved by ironing. Ironing makes the fabric crease free. Not only calendaring process makes the fabric crease-free but also it does a lot.

Advantages of Calendering

- The calender is very good at handling polymer that are heat sensitive as it causes very little thermal degradation.

- It is good at mixing polymers that contain high amount of solid additives that don’t get blended or fluxed in very well.

- Due to this calender is produce a large amount of melt than extrusion.

Disadvantages of Calendering

- It is a very expensive process to perform

- If the thickness is below 0.006 inches then there is tendency for pinholes and voids to appear in the sheets.

- If the thickness is greater than about 0.06 inches then there is risk of air entrapment in the sheet.

- So to achieve the desired thickness is also a very difficult process.

Facts of Calendering in Textile

- Provides highly lustrous appearance on the fabric surface.

- Provides smooth, glossy and silky touch to the fabric.

- Increases fabric cover factor

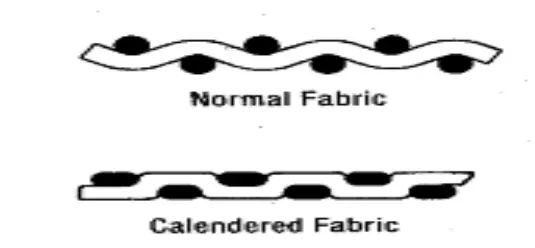

- Compress fabric and reduce thickness

- Causes a closing to-gather of the threads by flattening them & thus tending to fill up the inter stiches between warp and weft.

- Reduce air permeability by changing its porosity

- Increase opacity of fabric

- Reduce yarn slippage

- Flattens slubs

- Consolidation of non-woven

History of Calendering

The mechanized plain calender was in common use in the mid-18th century after having been introduced into England from Flanders in the 17th century. A special type called the friction calender was patented in 1805 by William Smith, and the schreiner calender was developed about 1895. Calenders for embossing and moiréing are other types in use.

How Calendering is Carried Out ?

When wet process is carried out on fabrics, the fabric loses its luster and remains at creased form. To compensate this problem, calendering is carried out.

3 Main Elements of Calendering

- Heavy pressure

- High temperature

- A suitable degree of dampness

Damping can be achieved in 3 ways:

- Brush damping

- Spray damping

- Damping by steam

Factors Which Influence the Effect of Calendering

- Press section number: the more pressure area passed, the more calendering effect on the paper, the higher natural calendering effect. But according to the structure of the calender, this seems to be the result of high pressure due to a large number of pressure areas, or more rollers. With the same line pressure, the results show that the number of press areas is high and the effect is good.

- Line pressure: the higher line pressure, the stronger the compression effect in the pressure area, the better the transfer effect. However, it must be pointed out that the improvement of its effect is limited. After a certain limit, the calendering effect will not be increased, and the mechanical strength of the paper will be greatly reduced.

- Working speed: General speed increases, the calendering effect will be reduced.

- Water: when the water content of paper page increases, plasticity increases, it is advantageous to pressure light, but when the water is too big, it will compress too tightly, make the transparency greatly increase, the page appears dark, namely the appearance of the black phenomenon. Therefore, water content is generally controlled at 6-8%.

- Temperature: the higher the temperature of the pressure zone, the more favorable the plastic deformation of the paper page, so as to improve the effect of calendering.

- Type of calendering roller: soft calender technology, the use of elastic roller absorbs the unevenness of paper, so that the paper completely and iron roller surface contact, after calendering the sheet tightness smoothly and continuous change, the sheet surface feature is invalid.

- Properties of paper pages: generally speaking, the paper pages are soft and plastic, easy to produce good transfer effect in the area of pressure, so as to improve the calendering effect.

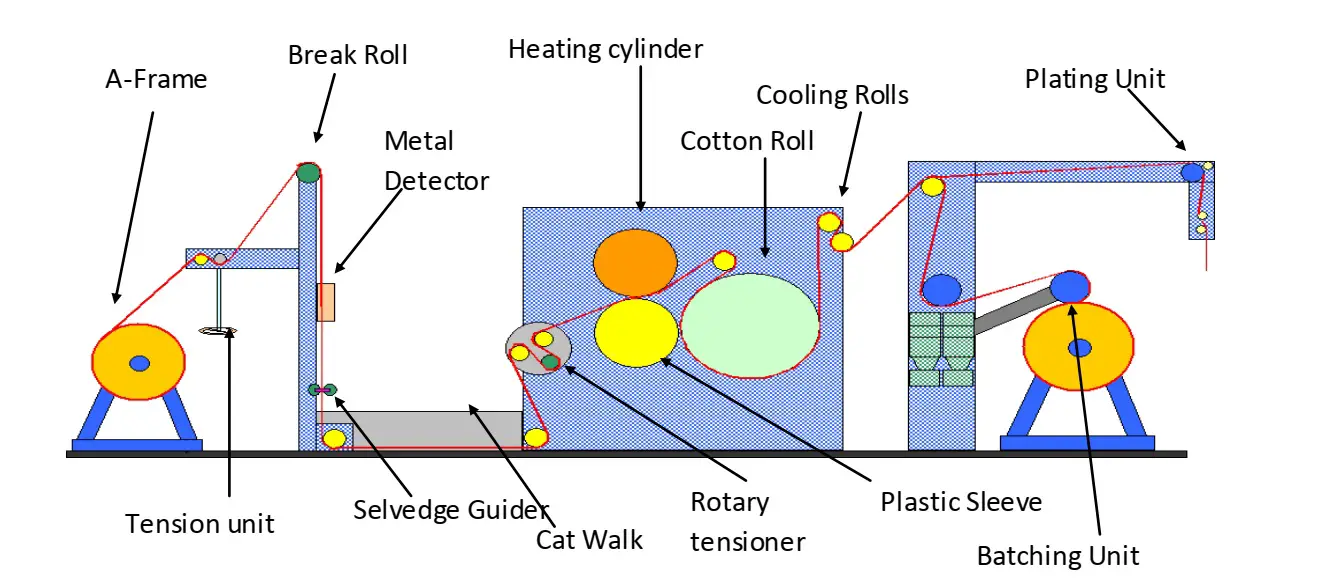

Calendering Machine Construction

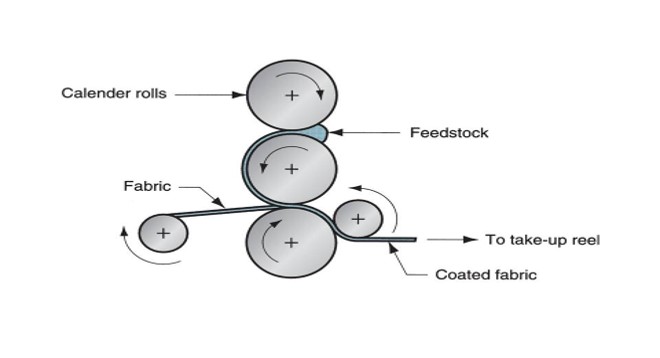

1 . Calendering machine consists of two or more massive rollers which are compressed by means of hydraulic or pneumatic pressure and have high temperature.

2 . The most important factor in calendar design is the composition of the rollers and the surface characteristics of these rollers.

3 . One roller is considered as the pattern roller and is responsible for finished appearance of the fabric.

4 . While the other roller is called ‘bowl’ and serve to transport the fabric through the m/c. Number of bowls 2-7.

5 . Normally no of bowls 3, 5, 7 with the most common being the three-bowl calendar. Number of bowls are more for heavy or jute fabrics.

6 . Two types of bowls are used:

A. Metallic (1/2 inch metal wire on bowl)

B. Compressed material (1/2 inch rubber or synthetic leather on bowl)

7 . Metallic and compressed bowl should be placed by one after another, otherwise fabric should be cut.

8 . However, a lot of modern calendars are made with thermoplastic thick covering which is usually Nylon

9. These are less liable to damage from knots, seams and creases.

10 . Nylon 6 covered rollers often enable the required effects to be achieved in a single nip thus reducing the overall number of bowls.

11 . Metallic bowl should be rotate with positive motion by gear to prevent slippage but compressed materials bowl should be rotate with surface contact.

Video of Calendaring :

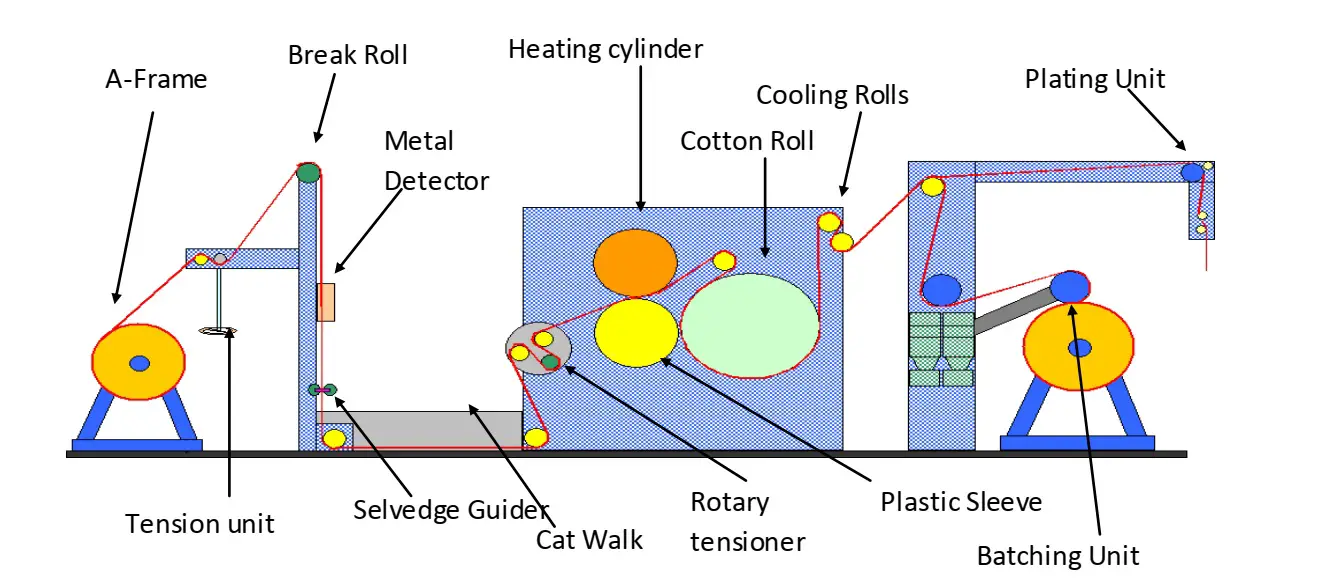

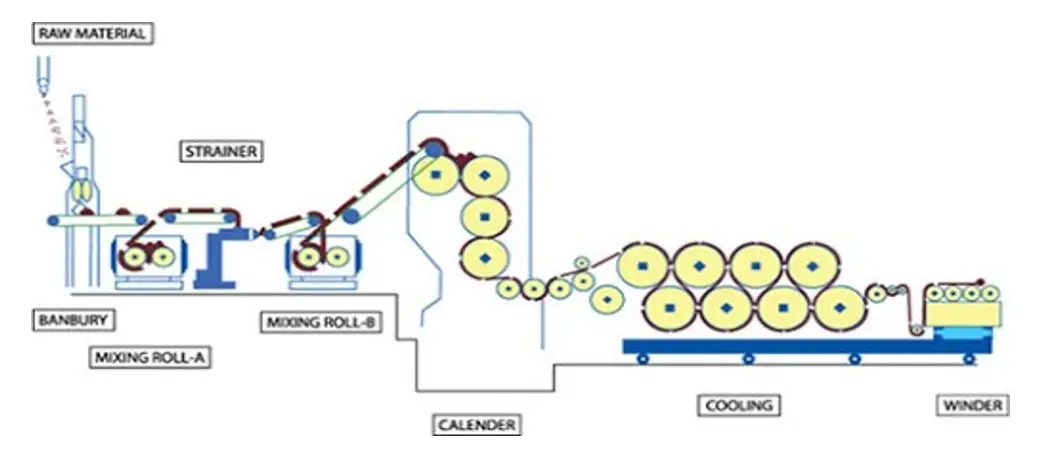

Passage Diagram of a Modern Calendering Machine :

Conclusion:

Exactly calendaring is used for woven fabric.Calendering is a thermo-mechanical technique that involves the use of heat and mechanical pressure, but not chemicals. Textile materials are taken through the method of calendering to enhance their aesthetic look and handle. Calendering is a kind of mechanical smoothing and segmenting procedure for ‘finishing’ fabrics or webs to create a special effect, namely flattening, luster, glazing, compacting, moiré, Schreiner, texturing, smoothing, and other embossed designs by passing in open width between two inline rollers kept under pressure.

The use of calender is a critical technique in finishing linen rayon, cotton, and silk materials. On the contrary, synthetic filaments react to mechanical deformation, but they need the presence of heat to conquest the physical and thermal memory of the fibers. The aim of standard calendering is to flatten yarns, to close interlacements in fabric, and to provide a lustrous, smooth touch to the fabric.

Calendering | Factors Effecting Calendering | Calendering Machine Construction

Types of Calenders in Textiles

Industrial Problems During Calendering & Troubleshooting

(358)