Ozone Technology in Garments Washing: A Sustainable Approach

The textile industry, particularly denim washing, has witnessed a paradigm shift with the introduction of ozone technology. This innovation has redefined sustainability by minimizing chemical usage, reducing water consumption, and enhancing process efficiency. Among the pioneers in this field, Ozon Denim has made remarkable advancements with its plasma modular ozone generators, ensuring consistent and high-quality denim washes.

How Ozone Technology Works in Denim Washing

Ozone (O₃) is a powerful oxidizing agent that effectively breaks down indigo dye molecules, achieving a desirable faded or vintage look on denim. The process involves:

- O₂ to O₃ Conversion: Ozone generators convert oxygen into ozone.

- Controlled Oxidation: The ozone generated reacts with the indigo dye, creating a bleaching effect.

- Decomposition & Safe Disposal: Post-processing, the ozone decomposes into oxygen, ensuring an eco-friendly process.

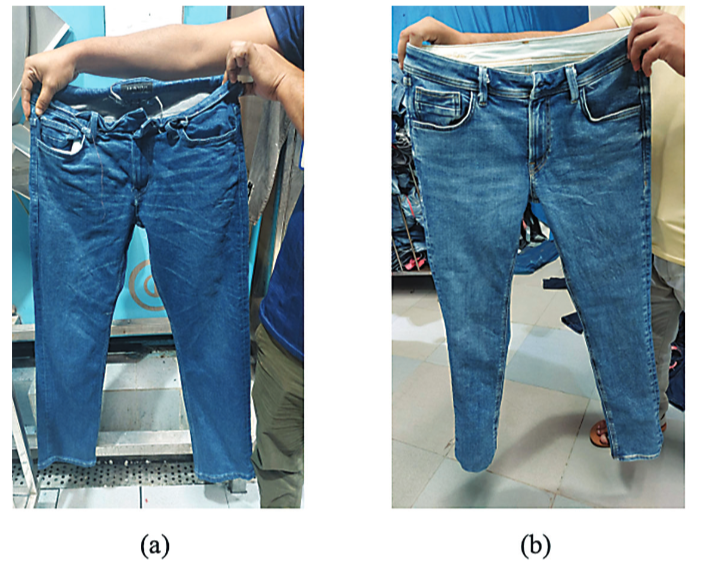

Unlike conventional denim washing techniques that rely on harsh chemicals, ozone technology significantly reduces environmental impact while delivering superior garment finishes.

Ozon Denim’s Technological Edge

Istanbul-based Ozon Denim has emerged as a frontrunner in sustainable garment washing by introducing plasma modular ozone generators. These generators stand out due to their:

- Efficiency: Capable of operating multiple tumblers simultaneously, reducing energy and resource consumption.

- Sustainability: Cutting chemical usage by up to 80%, water consumption by 60%, and electricity usage by 30-40%.

- Enhanced Denim Finishing: Ensuring uniform bleaching and a consistent vintage look without damaging fabric integrity.

Leading denim manufacturers in Bangladesh, such as Sterling Group, Mahmud Group, Envoy Group, and Vertex Group, have successfully implemented Ozon Denim’s technology in their production lines.

Eco-Efficient G2 Ozone Technology: A New Era for the Textile Industry

Jeanologia, a Spanish pioneer in sustainable textile technology, is revolutionizing the industry with its G2 ozone technology. Showcased at Kingpins Amsterdam, this innovation significantly reduces water and chemical use in denim and knitwear finishing. By harnessing ozone in atmospheric conditions, Jeanologia’s Atmos process enables dry-finishing, creating authentic vintage looks without water, pumice stones, or toxic chemicals.

This eco-friendly method slashes water consumption by 96% and cuts energy use by 25%, offering a cleaner and more cost-effective solution. Marketing Director Carmen Silla emphasized that air, rather than water, is now shaping the future of textile processing. With its patented INDRA system, Jeanologia continues to push boundaries, setting new benchmarks in sustainability.

With operations in 72 countries, Jeanologia’s technology is used in over 35% of global denim production, reinforcing its commitment to an ethical, digitalized, and pollution-free textile industry. This marks a transformative step toward a greener future.

Sustainability Benefits of Ozone Technology

- Reduces Chemical Dependency: Minimizes the need for traditional bleaching agents such as potassium permanganate and chlorine. Decreases chemical discharge, leading to a cleaner environment.

- Conserve Water & Energy: Traditional washing processes consume vast amounts of water. Ozone technology reduces water consumption by up to 60%. Less reliance on thermal drying and extensive rinsing translates to lower energy consumption.

- Eco-Friendly Processing: Ozone gas naturally decomposes into oxygen, eliminating harmful residues. Reduces textile wastewater pollution, aiding in responsible manufacturing.

Future of Ozone Technology in Garment Finishing

As sustainability becomes a priority for global fashion brands, ozone technology is expected to take center stage in denim processing. Innovations like Jeanologia’s Atmos System and Tonello’s O-Bleach Process have already demonstrated the industry’s shift toward air-based washing solutions.

With brands increasingly adopting circular fashion models, ozone-based garment finishing presents a viable path toward achieving zero discharge production, ensuring an eco-friendly and cost-effective future for denim manufacturing.

(266)