Laser in Denim Industry | Laser Technology

Laser in Denim Industry | Laser Technology | Mechanism of Laser Fading | Laser Finishing Process

Laser Finish :

Laser finish is an exceptional method which can create extraordinary jeans and reduce the environmental impact of this industry. In laser finish, there is no use of water, chemical, stones or sand to wash the jeans.

The finish is done using laser which goes across the jeans and burns into them. The process is very quick and the finishing effect look amazing. This water-free technology can give much wanted ‘distressed’ or ‘vintage’ look to the denim.

Laser technology has been adopted by some denim brands as an apt replacement for the traditional methods of denim finishing like sandblasting, stone washing, etc. It is the fastest growing and accepted technique in the denim market, as this technology has made denims go green. This method creates patterns like dots, lines, text and even images which are executed through computer managed process.

Laser technology :

LASER is light amplification by stimulated emission of radiation. Laser is an electromagnetic radiation, produced by the atoms due to energy states are changed in some materials. The atoms promoted to higher energy states emit laser in the form of light by the process known as “stimulated emission” Subsequently, this laser is being amplified in a suitable lasing medium with the help of mirrors. The final laser delivers from the equipment as a stream similar to light. The color of the laser depends on its wavelength. The most widely used unit used to express the wavelength of a laser is in nanometer (nm).

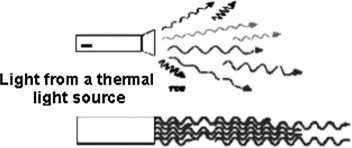

Laser light (Fig. 1) emitted from a laser has four fundamental characteristics: Intensity, Coherency, Monochromaticity, and Collimation, which distinguish it from natural light.

Laser is Coherent, monochromatic & nearly parallel.

Fig 1 : An ordinary light and a Laser beam

A high energy concentration per unit area of the beam is present in the laser. A laser beam can be of very high intensity with 1-2 mm of beam diameter and an output power of some milliwatts (mW). All the lasers are not powerful in spite of the light with high intensity as intensity is estimated from the power output/area. From Fig. 1 it can be observed that the ordinary light (from a thermal source) is incoherent, i.e., light waves are generated at different times and propagate in all possible directions randomly. However, laser is coherent as shown in the figure due to the waves are in phase while they propagate. Ordinary light is composed of all the colors in the visible region, but laser light is of a single color or monochromatic. The coherent nature in addition to the monochromaticity results in highly collimated laser. As all the waves propagate in same phase in parallel lines, there is almost no divergence as observed in light. This property of laser helps in achieving high intensity even after travelling a long distance. The energy concentration of the beam can be increased by manifold when the beam is focused as a point with the help of optical lens. For the production of the laser beam a lasing material is stimulated with electric dis¬ charge in an enclosed container. A number of partial mirrors help in multiple internal reflections that lead to obtain the desired coherency and power output. Mirrors or other optical devices help in focusing the laser to a lens, which then reflects the laser to the working zone. In order to enable the cutting action by a laser away from the edge, it should be pierced before the laser cut using a high-power pulsed laser beam.

Mechanism of Laser Fading :

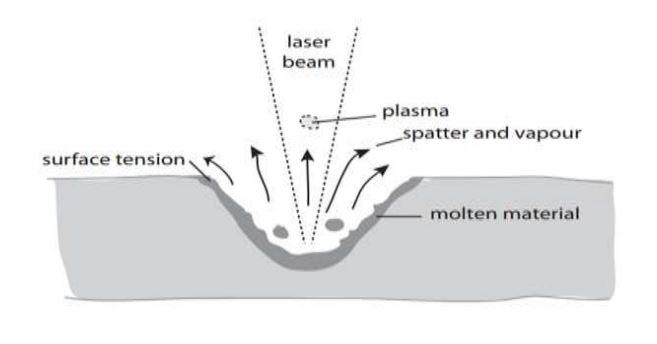

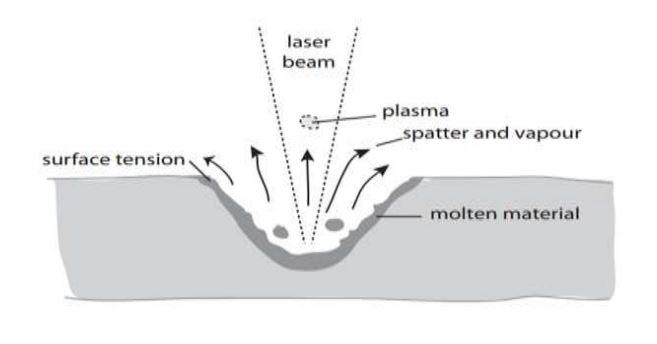

The laser works by creating extensive heat. Within the focused region, the material is subject to very

intensive heating within a very small region. Laser energy is absorbed as heat and the material rapidly

heats leading to melting as a phase change from solid to liquid takes place. Some of the molten liquid

tries to move, driven by surface tension of the liquid. The remaining liquid heats very rapidly, boiling

and releasing vapors another phase change takes place from liquid to gas.

Fig : Mechanism of Laser Fading

Laser Finishing Process :

A Laser finishing generally contains a system for delivering the beam, the work bed on which the

materials to be processed are placed, fume extraction systems and a housing which encloses the

system.

Laser is an energy source whose intensity and power can be precisely controlled. It is produced by

combination of CO2 +DC current. The laser is applied on the fabric according to the require

intensity. There are three parts in laser m/c- computer part, siler part (chemical section) & laser

part. The work bed may be of honeycomb structure or metal slats or metal rods (also containing

tiny holes).

Firstly, the design is made up in computer by Adobe Photoshop and then this design is transferred

to the laser machine placing the garments on the cutting bed. After according to the requirement

intensity, the laser ray applied on the focused design portion. This laser burns the surface of the

fabric. The fume extraction takes place from below the work piece and the spaces or holes enable

the gases to circulate and for processing debris to be sucked away from the work area. Whisker,

hand sand, grinding, fading, cut hole, image printing etc. can be done by laser blasting process.

Figure : Laser printing design in the computer

Stake in the global market

According to the latest data of Bangladesh Denim Expo, around 274 million meters of denim is produced per month by 26 factories operating in Bangladesh. The Bangladesh Export Promotion Bureau estimates the country exported finished denim products worth USD 430 million to the US and Euro 1.8 billion worth of products to the European Union in 2015.

Bangladesh hopes to become the world’s third largest denim exporter, after the US and Italy, in the next five years. The producers have set a target to export USD 7 billion of denim by 2021. The industry is already shifting from China to Bangladesh because of rising production costs and a shortage of workers.

Buyers and consumers have become more concerned about global warming and environmental hazards. That is why Bangladeshi manufacturers are installing technologies that consume less water and chemicals. The initiative is aimed at giving a cushion to the earth.

The global market for denim is projected to reach USD 64.1 billion by 2020, according to Bangladesh Denim Expo. If the country fails to make factories green and water efficient, it will fail to capture the global market, which is considered to be a golden opportunity for Bangladesh’s apparel makers.

The fear of failure is ultimately pushing the apparel businesses in the country to make themselves green.

As a method that saves water, improves production, lowers risks to workers, and also pleases global consumers, few initiatives are a better example of win-win as this shift taking place in Bangladesh’s denim factories

You May Look on Below :

- Laser in Denim Industry | Classification of Laser Technology

- Laser in Denim Industry | Laser Finishing Method | Flow Chart Of Laser Finish

- Laser in Denim Industry | Advantages and Disadvantages of laser finish | Laser safety

- Laser in Denim Industry | Laser Finish is Safe | Lasers Are Sustainable

- Laser in Denim Industry | Laser Technology

(280)