Sustainable Chemicals for the Garment Washing Industry: Paving the Way for a Greener Future

The garment washing industry plays a crucial role in the fashion and textile sectors, contributing to the final appearance and feel of clothing. However, traditional washing processes often involve high amounts of water, energy, and chemicals, leading to significant environmental challenges. In response to growing concerns about sustainability, the industry is embracing innovative and eco-friendly alternatives, particularly in the use of sustainable chemicals. These chemicals are designed to reduce environmental impact while maintaining the high quality of garment finishes that consumers expect.

The Need for Sustainable Chemicals in Garment Washing

Historically, garment washing has involved a heavy reliance on water-intensive and chemically hazardous processes. Traditional techniques, such as stonewashing and chlorine bleaching, have caused environmental degradation, including water pollution, hazardous waste disposal, and worker health risks. As the fashion industry faces increasing pressure to adopt sustainable practices, the use of sustainable chemicals is becoming a pivotal solution to address these issues.

Sustainable chemicals are designed to reduce the use of harmful substances, minimize energy consumption, and optimize water usage throughout the washing process. These alternatives also promote the circular economy by enabling garment recycling and reducing overall waste from production.

Key Sustainable Chemical Innovations

Several sustainable chemical solutions are being developed and adopted within the garment-washing industry. These chemicals serve as effective substitutes for traditional materials, offering enhanced performance while ensuring a lower environmental impact.

1 . Biodegradable Bleaching Agents: Conventional bleaching agents, such as chlorine and potassium permanganate, have long been the go-to solutions for achieving lightened or distressed looks in denim and other fabrics. However, these chemicals can be harmful to both the environment and workers. In response, biodegradable bleaching agents have been introduced. These eco-friendly alternatives are non-toxic, require less water during application, and don’t leave harmful residues in wastewater.

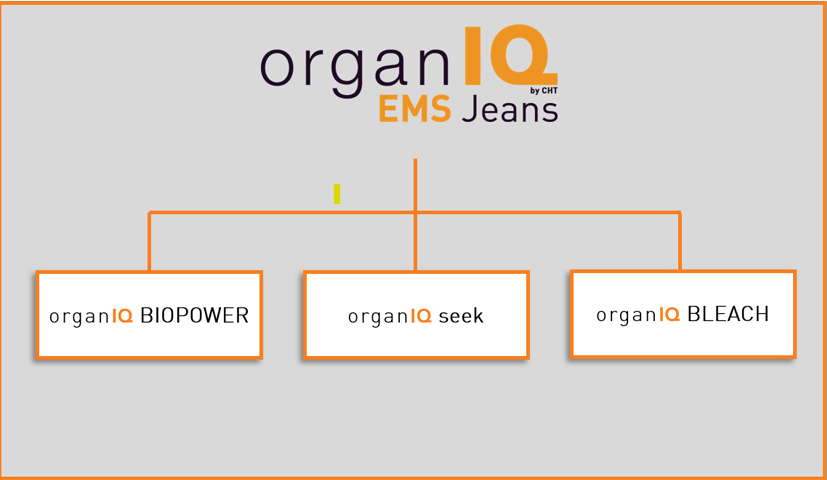

OrganIQ Bleaching, for example, is a biodegradable bleaching chemical that is both effective and safe for the environment. It eliminates the need for chlorine-based agents and reduces the production of harmful byproducts. The adoption of such alternatives helps garment manufacturers significantly reduce chemical waste, making the production process much cleaner.

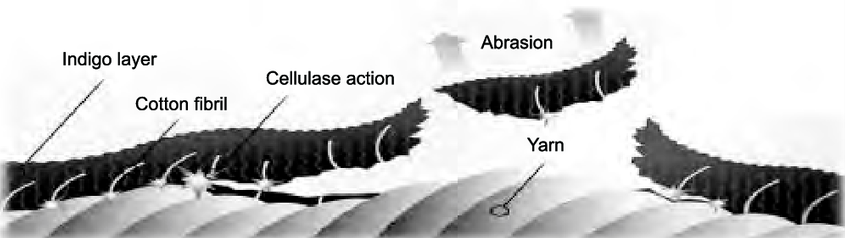

2. Cellulases for Stonewash and Biopolishing : Stonewashing is a popular method used to create a faded, worn-out look on denim garments. Traditionally, this process involved the use of pumice stones, which contributed to water and energy waste, as well as significant wear and tear on machines. Today, cellulases are being used as an eco-friendly alternative.

Cellulases are enzymes that break down cellulose fibers in the fabric, mimicking the effect of stonewashing. By using cellulases, manufacturers can achieve the desired worn look without the environmental cost associated with stonewashing. These enzymes are highly effective even at low temperatures, reducing energy consumption and improving the overall sustainability of the garment washing process.

In addition, cellulases are being used in biopolishing a process that reduces pilling and enhances the smoothness of fabrics. By using neutral or acid cellulases, manufacturers can improve the fabric’s appearance and longevity, contributing to sustainable garment production.

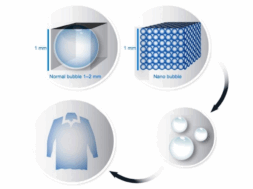

3 . Water-Free and Low-Water Wash Solutions : One of the biggest environmental concerns in garment washing is the vast amount of water used in traditional washing processes. From dyeing to finishing, water is heavily consumed and often polluted. To tackle this, sustainable chemical formulations are being developed that require little to no water.

NoStone®+ Technology, developed in collaboration with Levi Strauss & Co., is an innovative solution that eliminates the need for water in stone washing processes. This technology replaces traditional stones with mechanical treatments that achieve the same abrasive effect, but without the extensive water consumption and the energy costs associated with conventional methods. By adopting waterless solutions like No-Stone®, manufacturers can drastically reduce their water consumption and improve overall sustainability.

4. Anti-Backstaining Formulations : Indigo dye used in denim is prone to detaching during the washing process, which can cause unsightly stains on the fabric. Traditional solutions to this problem often involve the use of harsh chemicals that can damage both the garment and the environment. However, modern sustainable chemical formulations are designed to prevent indigo from detaching and staining the fabric without the use of harmful substances.

These anti-backstaining agents are formulated to retain the indigo dye within the fabric, preserving the garment’s quality while also ensuring that wastewater remains free from harmful pollutants. This innovation not only enhances the final product but also contributes to the broader goal of reducing chemical pollution in textile production.

5 . Enzyme-Based Softening Agents : Softening agents are essential for providing garments with the desired soft touch and luxurious feel. Traditionally, these agents were made from petroleum-based substances, which have a significant environmental footprint. Sustainable alternatives, such as enzyme-based softeners, are now being used to provide the same luxurious feel without relying on non-renewable resources.

Enzyme-based softeners also help delay the yellowing of indigo in denim, reducing the need for harmful chemicals that would otherwise be used for maintenance. These softeners also enhance fabric longevity, reducing the need for frequent replacements and promoting a circular economy.

(216)