Sustainable Effluent Treatment Plants (ETPs): A Key to Greener Garment Washing

Effluent Treatment Plant (ETP) :

Effluent is the excess chemical liquor discharged from an industry after its original use. Industrial effluent, which contains environmentally harmful materials, is treated with chemicals to neutralize or remove these toxins. This treatment occurs in an Effluent Treatment Plant (ETP). Nowadays, having an ETP is common for export-oriented factories due to compliance requirements and strict government regulations on environmental issues.

Sustainable Effluent Treatment Plants (ETPs): A Key to Greener Garment Washing

The garment washing industry, particularly denim finishing, is a significant contributor to water pollution due to the discharge of untreated wastewater containing harmful chemicals, dyes, and heavy metals. To address this, Effluent Treatment Plants (ETPs) have become essential for sustainable operations. ETPs not only help industries comply with environmental regulations but also reduce their ecological footprint, making them a cornerstone of sustainable practices in the garment-washing industry.

The Need for ETPs in the Garment Washing Industry

Garment washing processes, such as dyeing, bleaching, and stone washing, generate large volumes of wastewater laden with pollutants like:

- Heavy Metals: Chromium, lead, and cadmium from dyes and chemicals.

- Organic Compounds: High levels of Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD).

- Suspended Solids: Fabric fibers and chemical residues.

- Toxic Chemicals : Potassium permanganate (KMnO4), sulfides, and phenols.

Without proper treatment, this wastewater contaminates water bodies, harms aquatic life, and poses health risks to communities. ETPs are designed to remove these pollutants, ensuring that discharged water meets national and international environmental standards.

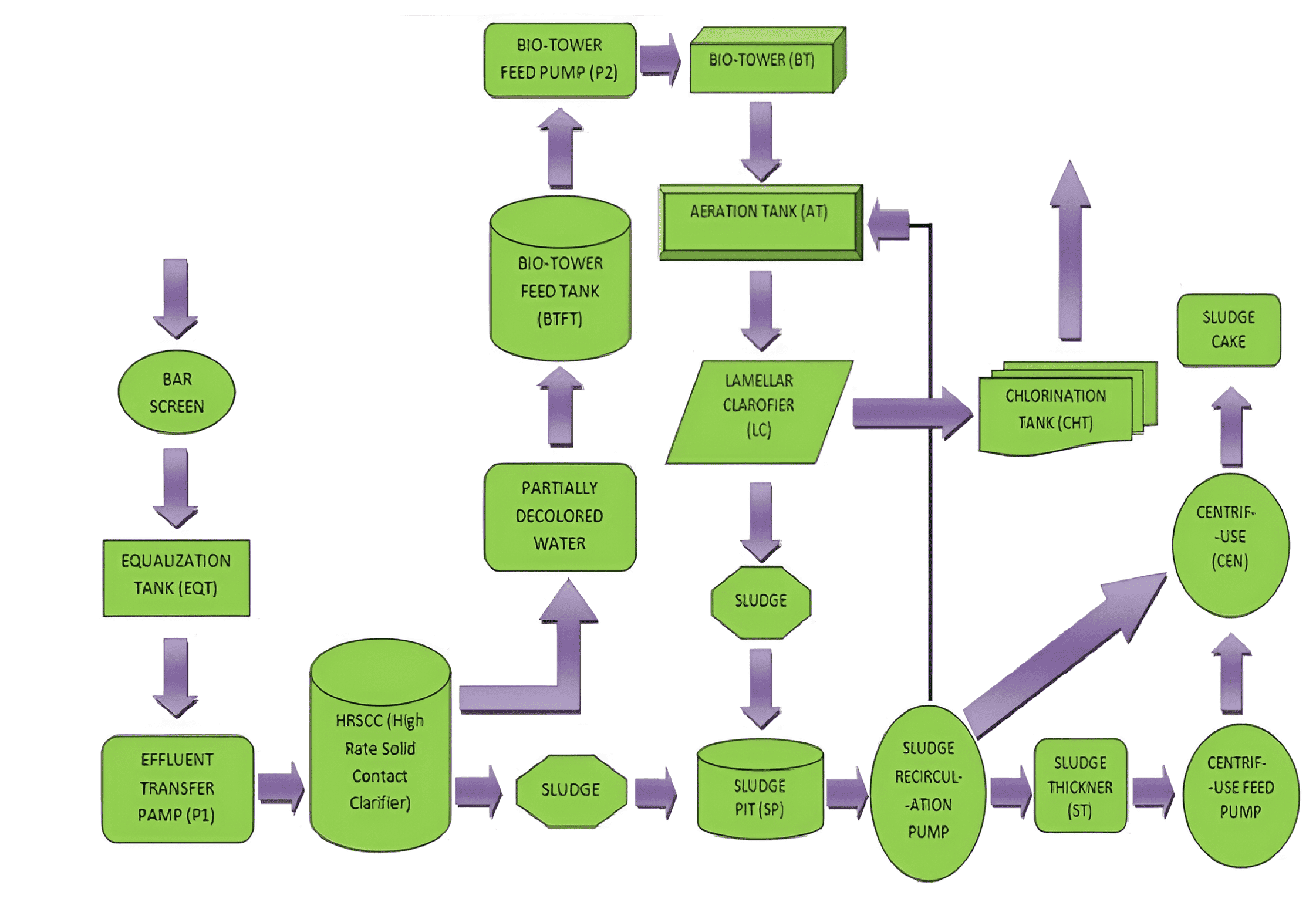

How ETPs Work: Key Treatment Processes

ETPs use a combination of physical, chemical, and biological processes to treat wastewater. Here’s a breakdown of the most common methods:

1 . Physical Treatment

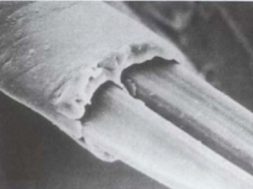

- Screening: Removes large solids like fabric fibers and debris.

- Sedimentation: Allows suspended solids to settle at the bottom of tanks.

- Filtration: Further removes fine particles from the water.

2 . Chemical Treatment

- pH Adjustment: Neutralizes acidic or alkaline wastewater using chemicals like lime or sulfuric acid.

- Coagulation and Flocculation: Adds chemicals like alum or ferric sulfate to clump fine particles into larger flocs for easier removal.

- Oxidation: Breaks down toxic chemicals using oxidizing agents.

3 . Biological Treatment

- Activated Sludge Process: Uses microorganisms to digest organic pollutants.

- Fixed Film Systems: Microbes grow on surfaces like plastic media, breaking down waste as water flows through.

Required chemical in Biological ETP

- H2SO4 : Neutralize the waste water controlling the PH. It is auto dispensed in the neutralization tank.

- Poly electrolyte : Used for sedimentation /sludge coagulation and alsokilling bacteria.

- Antifoaming Agent: Used for reduction / controlling foam. It is used auto / manuallyin the distribution tank.

- De-colorant : Used for removing color. It is used auto / manually in the sedimentation feeding tank.

- Sodium Hypochlorite : It is used to kill the harmful bacteria. It is used in the biological oxidation tank.

Product Quality Checked:

- Oxygen Demand (BOD) –

- Chemical Oxygen Demand (COD)

- Total suspended solids

- Total dissolved solids

- Color

- pH etc.

Major sources of liquid discharge are

- Scouring chemical

- Bleaching chemical

- Washing chemical

- Dyeing chemical

Innovations in ETP Technology

To address these challenges, the industry is adopting innovative solutions:

- Compact ETPs: Designed for small and medium-scale industries with limited space.

- Advanced Oxidation Processes (AOPs): Use ozone or UV light to break down complex pollutants.

- Membrane Filtration: Provides high-quality treated water suitable for reuse.

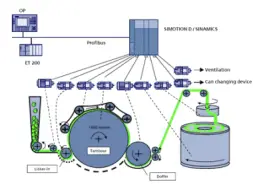

- Automation: Reduces manual intervention and improves efficiency.

The garment washing industry is no longer just about creating the perfect fade or softness—it’s about doing so responsibly. With the adoption of Effluent Treatment Plants (ETPs), manufacturers are taking a crucial step toward reducing water pollution and minimizing their environmental impact. ETPs, combined with groundbreaking technologies like laser fading, ozone washing, and E-Flow systems, are transforming the industry into a beacon of sustainability.

These innovations are not just eco-friendly; they are economically viable, reducing water and energy consumption while lowering operational costs. By eliminating harmful chemicals and conserving resources, the industry is addressing global challenges like water scarcity and climate change. Moreover, sustainable practices are enhancing brand reputations, attracting eco-conscious consumers, and opening doors to new markets.

(197)