Carding Action | Part 02

Part 01 | Carding Introduction | | Part 02 | Carding Action

Part 03 |Card Clothing | Types of card clothing | | Part 04 | Auto Leveling in Carding

Part 05 | Measuring Devices in Carding | | Part 06 | Characteristics of Card Sliver

Carding Action | Difference Among Carding Actions

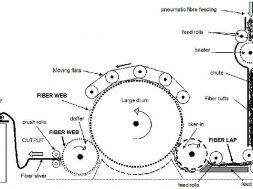

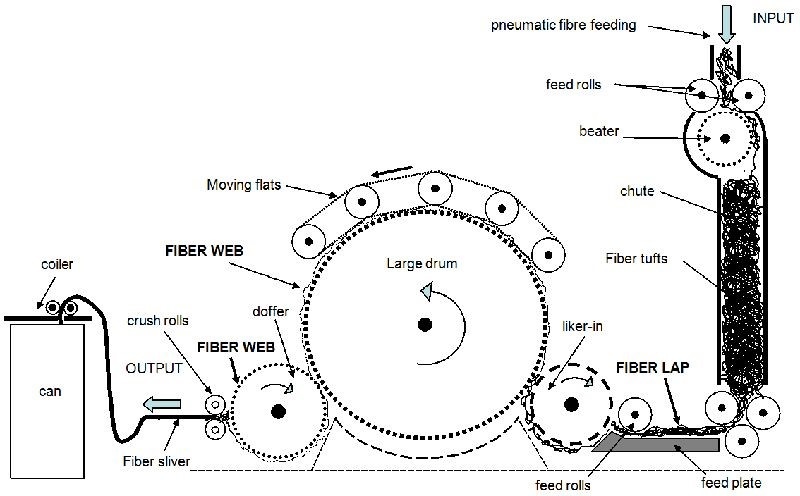

Carding: Carding is a mechanical process that disentangles, cleans and intermix fibers s to produce a continuous web or sliver suitable for subsequent processing. In this process fibers are opened, parallelized & removes dust, impurities, short fibers to produce continuous strand of sliver. This is achieved by passing the fibers between differentially moving surfaces covered with card clothing. The word is derived from the Latin “CARDUUS” meaning thistle or teasel, as dried vegetable teasels were first used to comb the raw wool.

Actions in carding machine:

I . Stripping action: when two close surfaces have same wire direction but their speed direction is opposite to each other, then the action between two surfaces is called stripping action. Opening and cleaning of fibers is done by this action.

- Action between taker in and cylinder

- Wire direction same

- Speed direction opposite

- Face to back arrangement of wires

II . Carding action: If two closed surfaces have opposite wire direction and their speed direction is also opposite to each other, then the action between two surfaces is known as carding action. Opening to individual fibers and neps removal is done by this action.

- Action between cylinder and flat

- Wire direction opposite

- Speed direction opposite

- Face to face arrangement of wires

III . Doffing action: when two close surfaces have opposite wire direction and their speed direction is also opposite to each other, then the action between two surfaces is known as doffing action. Web formation of fibers is done by this action.

- Action between Cylinder and doffer

- Wire direction opposite

- Speed direction opposite

- Face to face arrangement

Difference among carding actions:

|

|

Stripping action |

Carding action |

Doffing action |

|

Action occurs |

Taker in & cylinder |

Cylinder & flat |

Cylinder & Doffer |

|

Wire Direction |

Same |

Opposite |

Opposite |

|

Speed Direction |

Opposite |

Opposite |

Opposite |

|

Wire arrangement |

Face to back |

Face to face |

Face to face |

|

Function |

Opening & cleaning of fibers |

Opening into individual fiber & removing of neps |

Web formation |

Part 01 | Carding Introduction | | Part 02 | Carding Action

Part 03 |Card Clothing | Types of card clothing | | Part 04 | Auto Leveling in Carding

Part 05 | Measuring Devices in Carding | | Part 06 | Characteristics of Card Sliver

(3828)