Card Clothing | Types of card clothing | Part 03

Part 01 | Carding Introduction | | Part 02 | Carding Action

Part 03 |Card Clothing | Types of card clothing | | Part 04 | Auto Leveling in Carding

Part 05 | Measuring Devices in Carding | | Part 06 | Characteristics of Card Sliver

Card Clothing | Types of card clothing | Geometry of card clothing

Card clothing: The pin which is used to cover the surface of carding roller such as taker in, cylinder, doffer and are of fine in diameter, spaced closely and bended in shape is defined as card clothing.

Selection of card clothing:

- Type and design of card

- Rotation speed of the cylinder

- Production rate

- Material throughput

- Raw material type (natural or man-made fibers)

- Fiber characteristics (mainly fineness, length, bulk, dirt content)

- Overall quality requirements

- Price of the clothing

- Service offered by the clothing supplier.

Types of card clothing:

- Flexible card clothing

- Semi-rigid card clothing

- Metallic card clothing

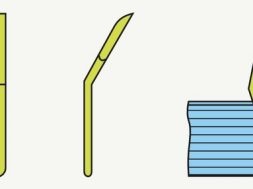

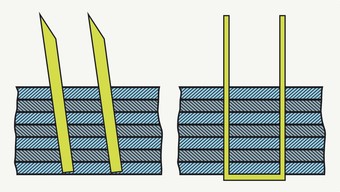

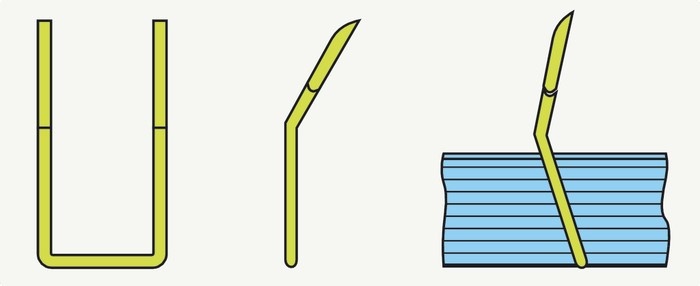

I . Flexible clothing: Flexible clothing have hooks of round or oval wire set into elastic, multi-ply cloth backing. Each hook is bent into a U-shape and is formed with a knee that flexes under bending load and returns to its original position when the load is removed.

Advantages of flexible clothing:

- Higher point density so better carding action

- Fiber damage is less due to flexible wire point

- Only the damaged part of the clothing is needed to be repaired

- Exerts desirable force on cotton causing good carding

- Less expensive.

Disadvantages of flexible clothing:

- Requires textile fabric or rubber as foundation material.

- The wires can be loosened

- Production less due to stripping

- Need regular grinding

- Wire and foundation maybe damaged as both wire and foundation are flexible

Fig: Flexible card clothing

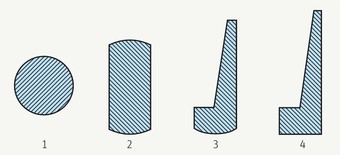

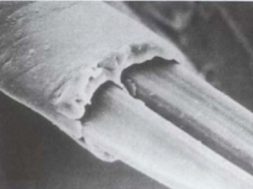

II . Metallic clothing:

These are continuous, self-supporting, square wire structures in which teeth are cut at the smallest possible spacing’s by a process resembling a punching operation.

Advantages of metallic card clothing

- Does not require separate foundation material. The metal surface of the machine works as foundation material.

- The teeth do not get loose as teeth and foundation both are metallic rigid.

- Can choose any carding angle

- Does not require regular grinding

- Production increases as regular grinding and stripping is not performed.

Disadvantages of metallic card clothing

- Fiber damage is more as the wire points are metallic.

- Difficult to repair in the mill when a portion of it is worn out

- If any part of the wire is damaged, then the total clothing is rewind.

- Expensive

Fig: Metallic card clothing

III . Semi-rigid clothing: Semi-rigid clothing have wires with square or round cross-sections and sharp points are set in backing which is less elastic than that of flexible clothing. This backing is a multi-ply structure with more plies than the backing of flexible clothing, comprising layers of both cloth and plastics.

Advantages of semi-rigid clothing:

- Does not choke with fiber

- Eliminate less flat stripping

- Does not need sharpening

Fig: Semi rigid card clothing

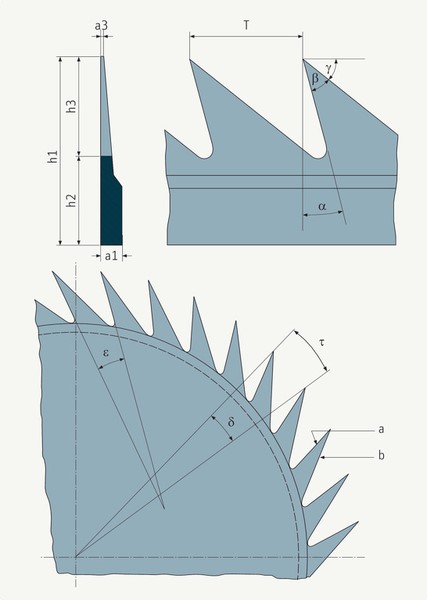

Geometry of Card Clothing:

|

Sl. No |

Name |

Symbol |

Comments |

|

I.

|

Base width |

a1 |

in mm |

|

II.

|

Tooth thickness at the root |

a2 |

in mm |

|

III.

|

Tooth thickness at the tip |

a3 |

in mm |

|

IV.

|

Overall height |

h1 |

in mm |

|

V.

|

Height of the base |

h2 |

in mm |

|

VI.

|

Depth of the tooth |

h3 |

in mm |

|

VII.

|

Tooth pitch |

T |

Spacing between successive tooth points measured with the wire stretched out |

|

VIII.

|

Carding angle |

α |

Angle between a line normal to the base of the tooth and the leading edge of the tooth, measured with the wire stretched out |

|

IX.

|

Tooth apex angle |

β |

Angle between the leading and trailing edges of the tooth |

Fig: Geometry of Card Clothing

Part 01 | Carding Introduction | | Part 02 | Carding Action

Part 03 |Card Clothing | Types of card clothing | | Part 04 | Auto Leveling in Carding

Part 05 | Measuring Devices in Carding | | Part 06 | Characteristics of Card Sliver

(6323)