An Overview of the Spinning Properties

An Overview of the Spinning Properties

Researchers from the textile industry of many countries have worked on the project to develop the nature of the spin produced by various natural sources. Engineer A.A. under the drafting of the spinning properties The study of sinyin has been the subject of the study and proposes to propose a proposal for two spinning spinners.

- Properties of spinning properties by studying the mechanic properties of the sheets and knowing how they move to the spin quality

- Properties of spinning products produced from mixtures based on specimens of spin yarn made from each component

It should be noted that the use of method 2 is currently not economically feasible. Evaluation of particle properties of equipment used during the first methodology of AAA SINSIN research is not sufficiently grounded. Among the many fundamental efforts to address the issues of foreign researchers are Professor P.Unenko, A.Novolov, K.Koritsky, VI. Будников, В.Е. Profesor Gusev and K.Razarumaev are well-known. The professor A.Novolovev assessed the position of the yarn in theory and practice as follows: <Ideally, the engineers and technologists are important in selecting and optimizing the raw materials, and using them to produce specific qualities of yarn>. The analysis of the spinning properties of OLSU Shubov has been conducted on a number of studies in the scope of the project’s spinning nature, and has been speci fi ed in detail by the various spinning properties of the spinning process, but does not seriously disturb the projection of the wool yarn. In addition, it also contains a compound characteristic of fittings, mechanisms, chemicals and applications, and is relatively expensive in raw materials. Therefore, this issue is specifically addressed. Researchers from Australia, New Zealand, England and Russia have been doing a bit more research on how the raw / non-wool / nature of the wool and yarns can affect the characteristics of the left and right combs. The study of the effect of the characteristics of raw material on yarns and semi-finished products can be considered as follows:

- Properties of spinning spinning of various natural elements other than wool

- Properties of wool yarn characteristics

- Properties of left tail combing properties

An overview of the nature of the spinning properties other than wool

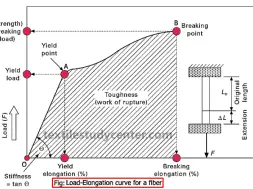

The first foundation project for the projection of a homogeneous character was the dissent of professor A.Novovyev. Professor A. The dependence of Soloviev cotton core spinning on the core of the load loads is based on a large number of test data, and the theory of uneven spin theory has been developed for the effects of vitality. Forecasting loads for spinning loads AN Sloovyev’s formula is expressed as follows:

P0 = 〖Pв x (〖10〗 ^ 3 Т) / Тв (1-0,0375Ho)〗 ^ -2.65 / √ ((〖10〗 ^ 3 Т) / ТВ) xZKfn

Here are: Po – Spinning loosening loads, sH / tex

PW- Load breaking load, SA / TEX

Тв – Linear density, linear

T – Linear density, texture

The quality of the nano-technology process is 3.5-4.4 times in fine combing and 4.5-5.0 in fine combing

Z-800 large length coefficient of coefficient, z = 1-C / Lh

C-constant coefficient and C = 5 for sponge

n – coefficient of probability of equipability of equipment, n = 0.95-1.1 normal operation n = 1

Determine the difference between the probability coefficient of the KF and the actual and critical coefficients.

Professor VA.Asensko has identified several factors that correlate between the loosening loads obtained from the wicker fibers. The predictive formula for spinning loads was similar to that of A.Novolov.

P0 = 〖Pв x (〖10〗 ^ 3 Т) / Тв (H -〗 ^ 2.8 / √ ((〖10〗 ^ 3 Т) / Тв)) xZβК

Here are: Po – Spinning loosening loads, sH / tex

PW- Load breaking load, SA / TEX

Тв – Linear density, linear

T – Linear density, texture

The spinning system technology is the coefficient of spinning irregularities attributable to the process, and for the dimensions of the whiskey sliced in precision, H = 0.87-0.91

2.8 – The coefficient determined by the test

Z – frictional and long-regression coefficient Z = 1-1.8 / Lf

f- friction coefficient

The coefficient calculated on the length of the strips of β- yarn loads

Calculate the effect of K-Fertility

ВА According to the Wiesenk, the tensile strength of the beams is expressed in bold.

Baz is the sum of the potential concentrations of 5 batches predominantly 1 mm apart from one another. Reducing the load of spinning will not affect the 50% reduction. According to the BATenko’s estimation, bumps are 50% or more, while β = 1, in other cases, are given in Table 1.1.

The value of the influence on β coefficients

Base,% 50 and above 45 40 35 30 25

β 1,0 0,99 0,97 0,94 0,90 0,85

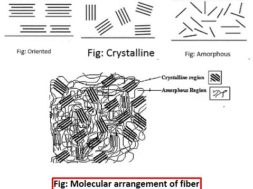

Professor V.Gomarov proposed a structure similar to the formula for determining the breakdown of spinning found. Professor K.I. The formula for the uniformity of the corrosion of homogeneous spinning is expressed as a more complex structure.

P0 = Pwm0 x [1- (0.18x 〖10〗 ^ (- 3) pвNвγ (m0-m0) Кф) / (μLEнε1√γв √Nв sin ^ 2β)]

Here are: Po – Spinning loosening loads, sH / tex

PW- Load breaking load, SA / TEX

The number of pieces in a cross section of m o

The number of pieces in the inner layer of m omega-y

Nw-Series number

Percentage of γ

KF-Eermetic cross-sectional area coefficient

The first modular, flexible module

ε1 – the relative strain of the grains in the spin yarn

μ- friction coefficient

L-length, mm

β – the angle of the outer layer spinning axis

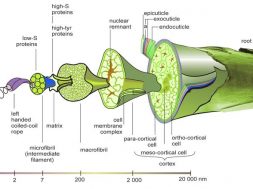

An overview of the nature of the artificial yarn produced by the wool

The drafting of spin fibers derived from wool has been the first time in the Russian research article to work on the engineer A.Alexis. Thus АА In determining the nature of the woolen yarn characterized by several components of sinexin,

Samples of 5-10 kg of each mixed ingredient

Samples taken from each component shall be sent to the same equipment on a similar or similar environment to the specimens of the project.

The characteristics of the spinning properties of each component are determined by the following equation:

A = Σ_ (i = 1) ^ n▒αi aiAi

Here is: A- Characteristics of the projection of spin produced from the Holi ion

Specifications of the yarns obtained from Ai-i

n- the number of spinning elements

αi – i component in mixtures,%

a – the coefficient for the use of the yarn characteristic of the component, in this case it is assumed to be A. A. Sinice αi ≤ 1.

- A. SINICINO recommends determining the linear density, loads, stretches, and outputs of the wool spin yarns by its own formula. In practice, AI = 1 is used in the AACS formula. To calculate the load burden loads from the spinning loads, the formula A is used to estimate the use level.

K = Po / Poв

Here is the coefficient of load loads relative to K-fiber spinning load

Relative loads of Po breakdown

POV – relative loads of wool spikes

The relative load for AEM SINXIN’s recommendation is to use K = 0.27-0.31, while O.Y. The value of K = 0,24-0,86 was calculated. In the AAA Synchin formula we calculated the design and quantity of the wastes used in the AG.

K = (Σ_ (i = 1) ^ n▒αi Ai) / (1-Σ_ (i = 1) ^ n▒Ki βi)

Here is the number of n-natural wool mixtures

The number of mixtures composed of m-plant costs

Ki-≤1 is the coefficient of quantitative determination of the tailings for cereal wool

Share of waste mixtures.

The formulation of homogeneous wool spinning properties for O.B.Berzine is defined as the formula for AO N.Solovyev and V.Asenko.

P = 〖Px xsx (0.018 -〗 ^ 0.063dв / (10x√ (Т / 1000))) Кn

Here is: P- yarn burden loads

Pw- wool load loads

s – wool value (wool from Bradford classification)

dwarf wicker fine, μm

Linear density and texture of T yarns

The coefficient of the C-implicative coefficient (similar to the formula of A.Novolov)

n- the coefficient of estimating the efficiency of the technology

О.Я. There were several disadvantages when using Beretin formula in practice.

The length and length of the woven woven length are not uniform, and the weight of the weld is not specified.

The test for the impact of the impact reinforcement 125 was determined by experiment, but this figure was 95-135.

s quantities do not adequately state the nature of the wool fibers, which are significantly different from those of the wool.

The introduction of the technology effectiveness into the subject does not necessarily reflect the efficiency of the technology.

In the early 1970s, AKP Coborhenikov’s dissertation on the Department of Wool Technology was studied by the complexity of the pure wool particles. In calculating the number and break load of spinner, many composite models are shown below.

P = 35.5 + 1.96Lw-1.12Clв + 6.13Pw-4,84Ew-1.26Cev + 2.45K + 3,91Т

Po = 1.691 + 0.025lв-0,023Слв-0.011dв + 0,035 Пв + 0,003 К + 0.004Т

Chō = 296 + 17.25dw-2,77Lw-22,53PВ + 0.98Скв-0,19Eв-1.98К-0.054Т

Here is the absolute load of P- yarn breaking, Sn

Compressive load relative load, C / texture

Breaking time for chaw-spinning, number of breaks in 1000 threads

Lw- wool length, mm

It is not smooth along the length of the slab-wool

dw – fine wavy wool, μm

Pw-wool loads loads, Сн

The union is unbelievable along the loads of the buffer wool,%

Extension of fiber breakage,%

The elongation of Cev-wool strands is uneven

Linear density and texture of T-yarn

K-yarn intensity, the number of turns in the 10cmС

Copyright : Munkhtuya

(45)