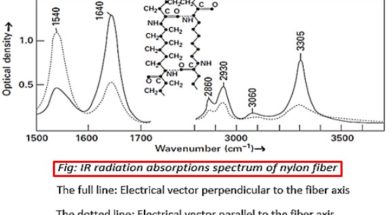

Absorption of IR radiation method

Infra-red (IR) spectroscopy is one of the most common and widely used spectroscopic techniques. When electromagnetic waves interact with matter, they are scattered and absorbed. Infrared spectroscopy, radiation with wavelengths between 1 -15 μm is absorbed at certain characteristic frequencies, which yield structural information.