INTRODUCTION TO TAPPET SHEDDING

INTRODUCTION TO TAPPET SHEDDING

1.What is shedding?

Ans: It is the first primary motion. Shedding is the process of dividing the warp yarns into two layers.

Note: To separate the warp thread into two layers – One layer is raised and the other layer is lowered.

2.What is shed?

Ans: The passage tunnel or space between two layers of the warp yarns.

3.Types Of Shedding Mechanism

There are four types of shedding mechanism. They are:

- Tappet shedding

- Dobby shedding

- Jacquard Shedding

Combined Shedding:[ Tappet+Dobby ; Dobby + Jacquard ; Jacquard + Tappet]

4.What is Tappet Shedding?

Ans : It is a shedding mechanism where shedding is done by means of tappet(cam).

5.Principle Of Tappet Shedding :

The principle of tappet shedding motion consists in using a tappet which impinges upon an Anti friction roller or bowl, supported in a treadle, the heald shaft being directly or indirectly connected to the treadle from which it is operated.

6.Types of Tappet Shedding :

There are mainly two types of tappet shedding.

They are:

- Positive Tappet

- Negative Tappet

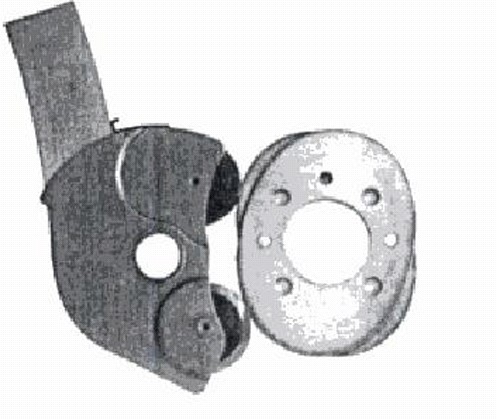

A.Positive Tappet Shedding :

In this type of shedding positive tappet(cam) is used for shedding. The positive shedding cam (tappet) give both upward and downwards movements to healds without the aid of any additional mechanism.

Types of Positive Tappet Shedding :

- Woodcraft’s section tappet

- The oscillating tappet

- Nuttall’s chain tappet

- Scroll tappet.

B.Negative Tappet Shedding :

It is the type of tappet shedding where shedding mechanism is done by means of negative tappet (cam). The negative shedding cam gives one direction movement that means it gives upward or downward movement.

Types of Negative Tappet Shedding :

- The ordinary plain and twill weave shedding tappet

- Jamieson’s Tappet

- The barrel Tappet.

7.Advantage Of Tappet Shedding :

A. Simplest and Cheapest Mechanism.

B. Give best result within its capacity.

C. Action is certain

D. Capable of lifting heavy weights with less wear and tear of the machine.

E. Open shed is created.

F. Warp strain less.

G. Fabrics defects fewer.

H. Less power consumption.

I. Maintenance is easy.

8.Disadvantage :

A. Less number of heald frame used.(Maximum number of heald frame is 14 but practically 6-10)

B. Need heald staggering.

C. complex design can not be obtained.

D. For faulty tappet jerky movement obtained.

E. When design is changed need to change the cam,that is expensive and time consuming.

So frequently design change is not suitable.

9.Scope Of Tappet Shedding :

A. suitable for weaving plain, twill design.

B. comparatively economical mechanism.

10.What is cam?

Ans: A cam is a disk that transform a rotational motion of its own to a reciprocating motion of a follower.

Note: The transfer is done by means of the cam edge or a groove cut in its surface.

11.Types of cam:

There are two types of cam:

A.Positive cam

B. Negative cam.

Positive cam:

The harnesses are both raised and lowered by tge cam.

Types:

- A frictionless roller follows a groove machined in the face of the cam.The cam follower, which is attached to one end of a lever,moves up and down and the lower end of the lever moves back and forth in the horizontal direction. Then the motion carries to the harness frame by means of various lever. This type of mechanism is not used much more.

-

A pair of matched cams are used for each harness.The frictionless rollers which are in the contact with the cam faces oscillated the lever about its fulcrum. As a result a reciprocating movement is obtained in the lever . This type of machine is common in modern weaving machines.

12.Motion transfer Of Tappet :

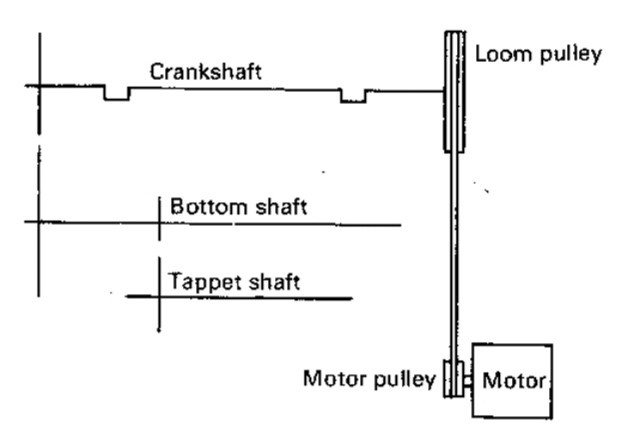

Motor -> Motor pulley -> Machine pulley-> Crankshaft ->Bottom shaft -> Tappet shaft

13.What is dwell?

Ans : It is the stationary period of healds,while shuttle passes through the shed.

14.Why more than 8-10 healds frame can not be used in tappet loom?

Ans: There are two basics reasons-

A. The dwell period is not enough for passing the shuttle through the shed.For this the possibility of shuttle trapping between the shed is increased, that causes the more warp breakage.

B. If heald staggering is not done then the space for shuttle passing will be decreased. That causes more warp breakage.

15.Calculation of loom cycle :

The speed of loom is measured in P.P.M unit(P.P.M= Picks Per Minute)

Generally, Motor R.P.M.= Loom P.P.M

Let, The P.P.M. of loom is 120.

That means the number of picks insert in 1 minute (60sec) is 120. In another way we can say 120 loom cycle is completed in 1min(60sec).

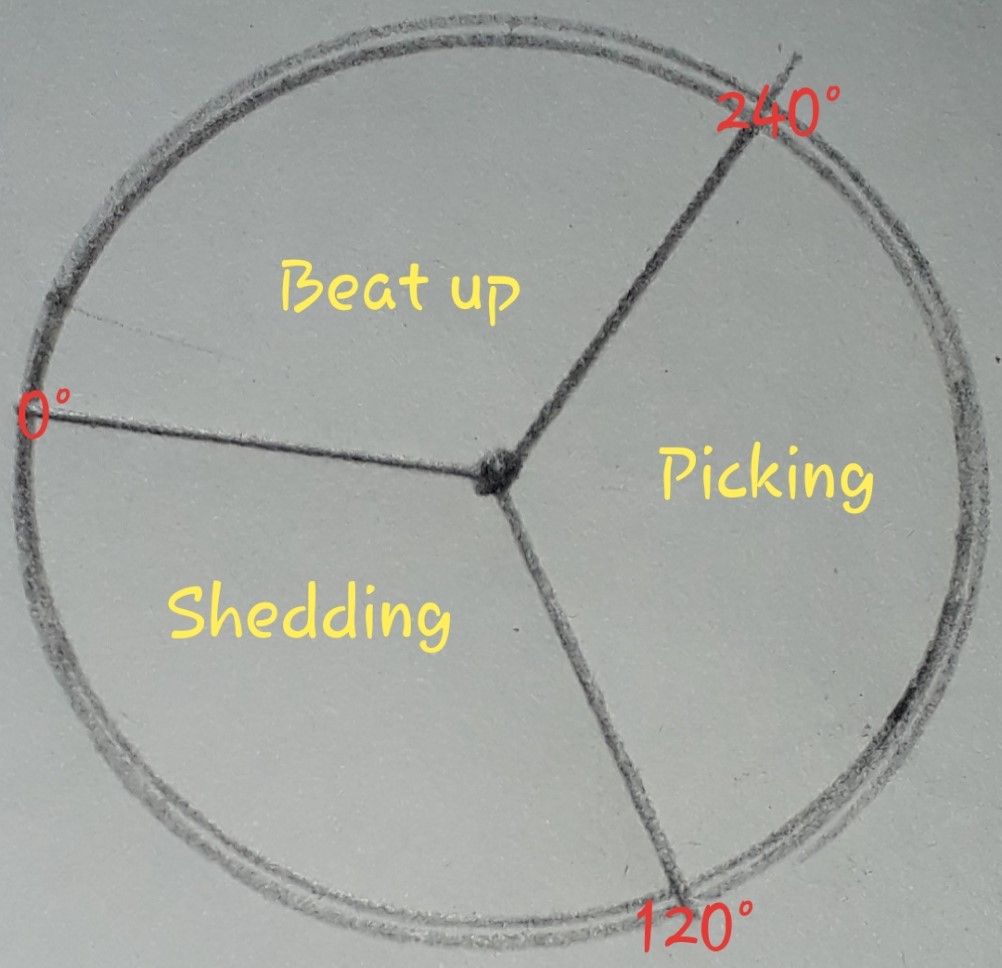

Here shedding is done within 0°-120° of the rotation of crank shaft.

Picking is done within 120°-240° of the rotation of crankshaft.

Beat up is done within 240°-360° of the rotation of crankshaft.

Time for 120 loom cycle = 60 sec

So,time for 1 loom cycle = (60/120)

=(1/2)

The crankshaft rotate 360°( one shedding, one picking, one beat up) in (1/2) sec

So time for one shedding that means time for rotation of crankshaft 0° to 120° is =(1/2)*((120-0)/360)

That means time for shedding = time for 1 loom cycle*(angle for shedding / 360)

Similarly,Time for one picking = time for 1 loom cycle *(angle of picking / 360)

Time for one beat up = time for 1 loom cycle*(angle of beat up/360)

Exercise :

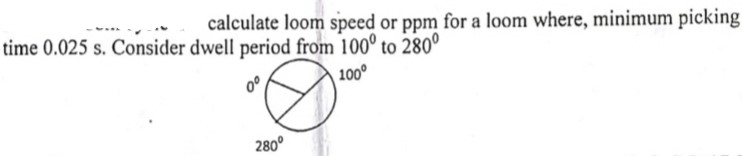

Here,Picking time = 0.025 s

Dwell period = picking angle = (280-100)=180°

We know,Picking time = time of 1 loom cycle * (picking angle /360)

Or, 0.025 s = time of 1 loom cycle*(180/360)

Or, 0.025 s = time of 1 loom cycle *(1/2)

Or, (2*0.025) s= time of 1 loom cycle

Or, (1/20) s = time of 1 loom cycle

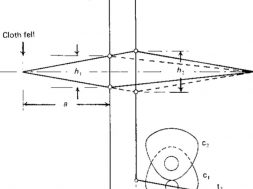

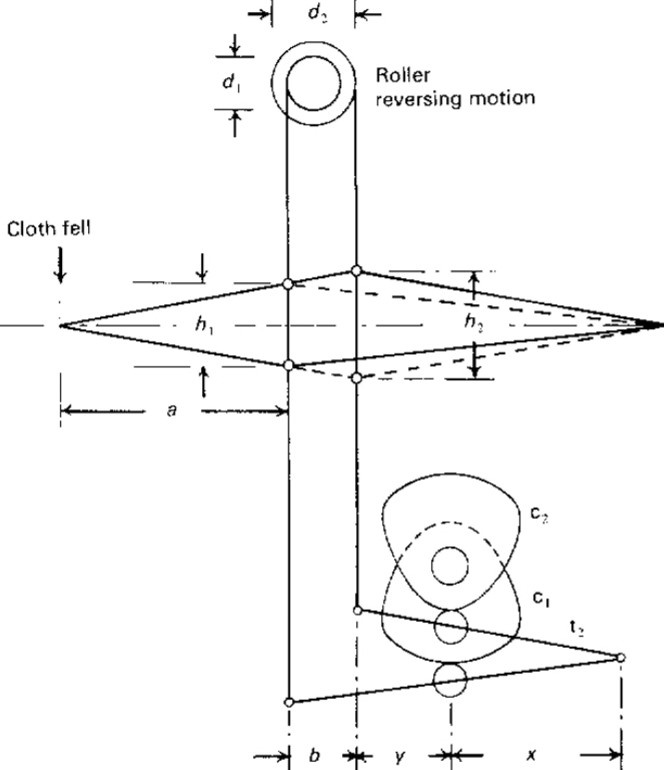

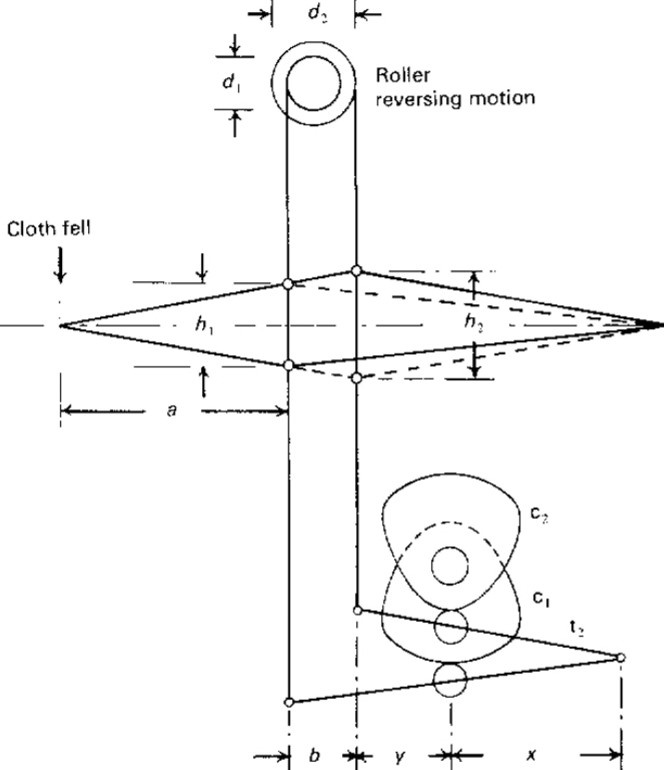

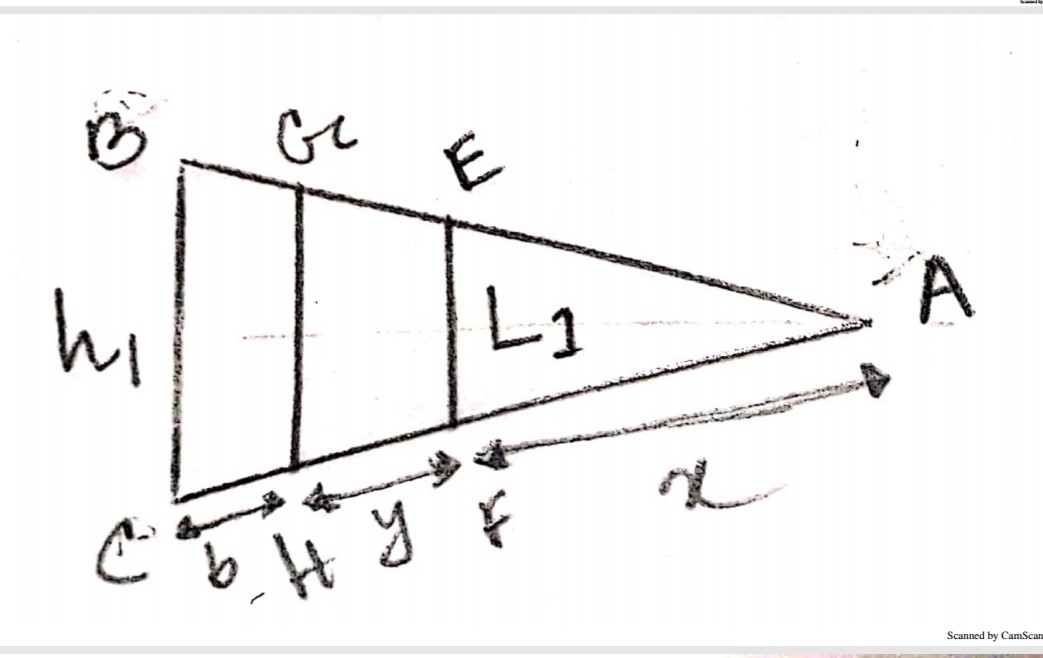

Lift (throw) of the cam:We need more vertical movement in back healds. The effective length of treadle lever is shorter that’s why the vertical movement of the front heald is more. For overcome this problem The lift (throw) of C1 cam is should be less than the throw of C2.

Here,

X= Distance between the fulcrum point of treadle levers and the centre of the treadle bowl.

Y= The distance between the centre of the treadle lever tied with the back heald.

b=distance between the front and back heald.

a= distance between the cloth fell and front heald.

h1 and h2= The lift of the front and back healds respectively.

L1= Lift of the cam that controlled front heald.

L2= Lift of the cam that controlled back heald.

The lift of a heald is equal to the movement of the tip of the corresponding treadle lever.

Now applying the concept of similar triangle :

From triangle ABC we get

(h1/L1)={(x+y+b)/x}

Or,L1= [(h1*x)/(x+y+b)]………………………………….<1>

(2980)