Raschel Machines | Features, Knitting Cycle & Application of Raschel Machines

198

0

Raschel Machines | Features, Knitting Cycle & Application of Raschel Machines

Raschel Machines

Raschel machines for producing stretch and non-stretch sportswear, lingerie and tulle, as well as fine and coarse nets.

Raschel knits do not stretch significantly and are often bulky; consequently, they are often used as an unlined material for coats, jackets, straight skirts and dresses. These fabrics can be made out of conventional or novelty yarns which allows for interesting textures and designs to be created.

Raschel Machines Main Parts :

- Front Roller

- Back Warp

- Warp Tension Roller

- Knitting Elements

- Fabric Take Up Roller

- Take Up Beam

- Machine Bed

- Main Eccentric Shaft

- knitting element Drive

Features of Raschel Machines :

- Raschel machines normally use latch needles and compound needles also used.

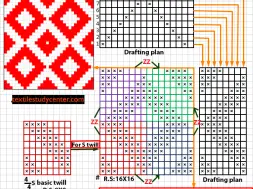

- The gauge is expressed in needles per 2 inches. The most common gauges are 30,40, 56.

- The chain links are numbered in even numbers 0, 2,4,6.

- Raschel sinkers only perform the function of holding down the loops while the needles rise.

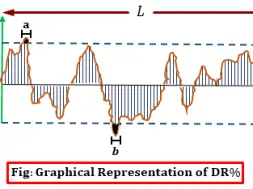

- The fabric is drawn downward from the needles almost parallel to the needle bar at an angle of 120-160degrees by a series of take down rollers.

- The guide bar are threaded commencing with the needle bars.

- The guide bars are numbered from the front of the machine.

- In a raschel machine there is acommodation for at least 4, 32inch diameter beams or large number of small diameter pattern beams.

Front view of Raschel Machine :

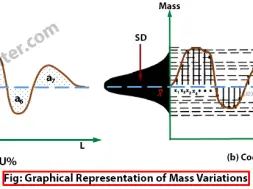

Raschel M/C Knitting Cycle :

Raschel Machine – Crosssectional View :

Video of Raschel Machine :

Application of Raschel Machines :

- Fishing nets,

- Protective net,,

- Purse net,

- Shading net

- Fence net/ Bird net

- Olive net,

- Garment net.

You May Look :

(198)