Textile Technology in Spacesuit

Textile Technology in Spacesuit

Spacesuit:

A space suit is a garment worn to keep a human alive in the harsh environment of outer space and temperature extremes.Space suits used by the astronauts during space shuttle missions represents the ultimate protective clothing . They protect the astronauts from heat ,cold , chemical, micrometeoroids, pressure fluctuations and temperature extremes.Spacesuit may be an example of growing development of textile technology.

Raw Materials for Space Suit Manufacturing:

The different materials which are used to make spacesuit are:

- Nylon Tricot

- Spandex

- Urethane coated Nylon

- Neoprene coated Nylon

- Mylar

- Kevlar

- Dacron

Requirements of a Spacesuit:

- Have a pressurized atmosphere.

- Have sufficient oxygen supply.

- Eliminate carbon dioxide.

- Maintain a proper temperature despite of strenuous work and movement.

- Protect from micrometeoroids.

- Protect from radiation to some degree.

- Enable clear vision.

- Allow easy movement of the body inside the spacesuit .

- Enable easy conversation with others such as ground controllers, other astronauts etc.

- Facilitate movement around the outside of the spacecraft.

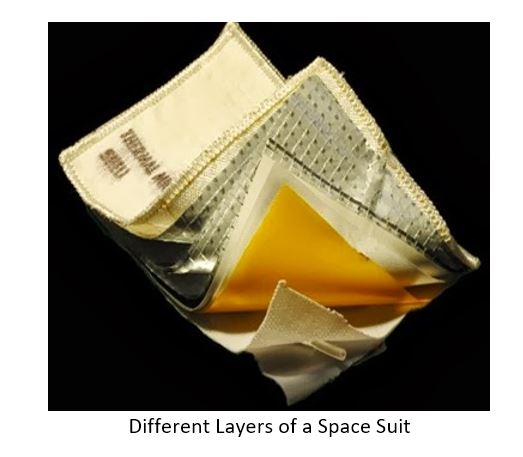

Different Layers of a Space Suit:

- A water-cooled Nylon undergarment

- A multi-layered Pressure suit :

( A ) Inside Layer : Light weight nylon with fabric vents.

( B ) Middle-Layer: Neoprene coated Nylon to hold pressure.

( C ) Outer-Layer : Nylon to restrain the pressurized layers beneath.

- Five Layers of Aluminized Mylar interwoven with four layers of Dacron for heat protection.

- Two Layers of Kapton for additional heat protection.

- A layer of Teflon-coated cloth (non-flammable) for protection from scrapes.

- A layer of White-Teflon coated cloth (non-flammable)

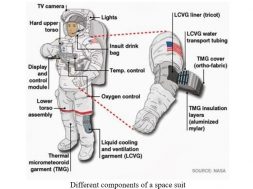

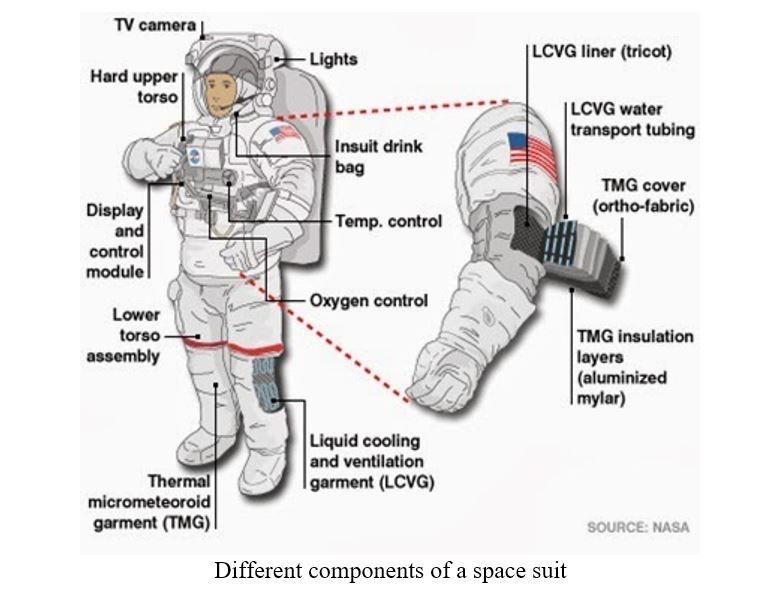

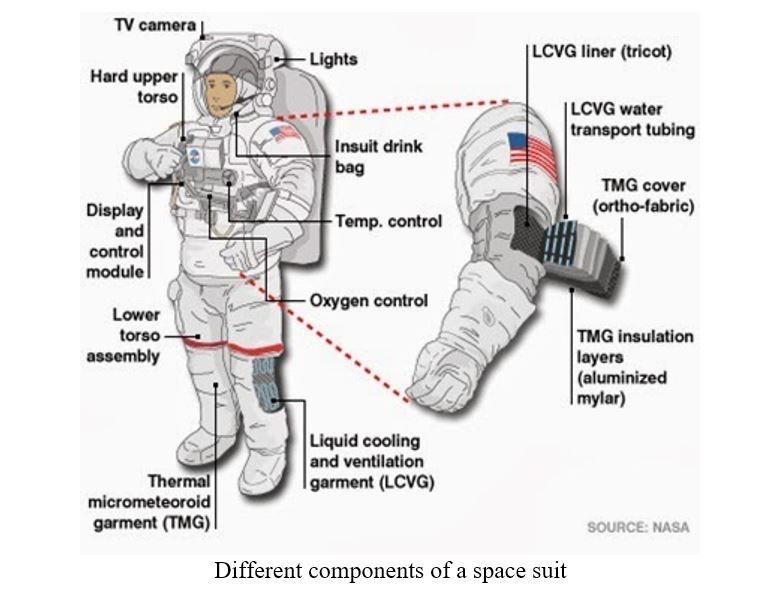

Components of a Space Suit:

1 . Liquid Cooling Ventilation Garment (LCVG): It is a set of Nylon Tricot and Spandex “long underwear” that is laced with thin plastic tubes through which,cool water flows which eliminates the excess body heat produced by the astronaut.

2 . Communication Carrier Assembly (CCA): The communication carrier assembly is a cap worn by the astronaut which contains microphones and earphones enabling hand-free communication. This skull cap is made up of Teflon and Nylon/Lycra fabrics.

2 . Communication Carrier Assembly (CCA): The communication carrier assembly is a cap worn by the astronaut which contains microphones and earphones enabling hand-free communication. This skull cap is made up of Teflon and Nylon/Lycra fabrics.

3. Maximum Absorption Garment (MAG): Helps in collecting body wastes and its storage during spacewalk.

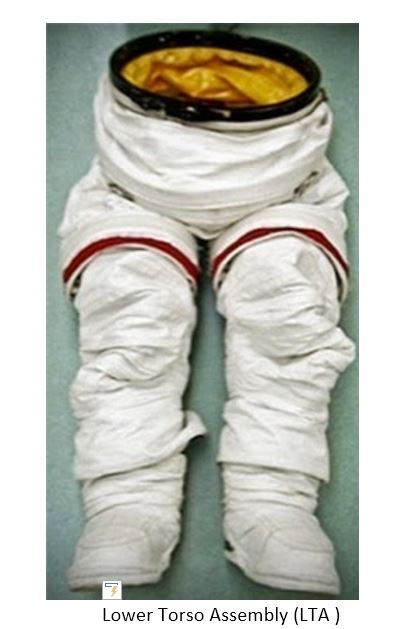

4. Lower Torso Assembly (LTA): This LTA is a single unit which includes pants, knee and ankle joints, boots and lower waist. A metal connect ring facilitates its fitting. The LTA has loops to join the tools preventing them from floating away in space.

5 . Hard Upper Torso (HUT): It is a hard fiberglass shell that supports several structures including the arms,helmet, life-supporting back-pack and control module.

6. Arms: Arm unit holds shoulder, upper arm and elbow joint bearings enabling the astronaut free movement of his arms in any direction. The arm units are of various sizes so that they can be fitted to different astronauts.

7. In-Suit Drink Bag: It is a plastic pouch placed inside the HUT and can hold 32 ounces (1.9 liters) of water and has a small tube something like a straw that is placed next to the astronaut’s mouth.

8. Gloves: Gloves aid easy movement of the wrist bearings. They are attached to the arms by quick-connect rings. For a proper grip on things, gloves have rubberized fingertips. Astronauts also wear fine-fabric gloves inside the outer glove units for comfort.

9 . Helmet :The helmet is made of clear, impact-resistant, polycarbonate plastic, and is attached to the HUT by a quick-connect ring. The helmet is padded in the rear for comfort; it has a purge valve to eliminate carbon dioxide if the backup oxygen supply has to be used. In the helmet, oxygen flows from behind the astronaut’s head, over the head and down his or her face. The inside of the helmet is treated with an anti-fog compound before the space walk.

10 . Thermal Micrometeoroid Garment (TMG): An (Integrated) Thermal Micrometeoroid Garment (TMG or ITMG) is the outer layer of a space suit. The TMG has three functions:

10 . Thermal Micrometeoroid Garment (TMG): An (Integrated) Thermal Micrometeoroid Garment (TMG or ITMG) is the outer layer of a space suit. The TMG has three functions:

- To insulate the suit occupant and prevent heat loss,

- To shield the occupant from harmful solar radiations,

- To protect the astronaut from micrometeoroids and other orbital debris which could puncturethe suit and depressurize it.

These are the basic structure of a space suit.But with the development of advanced textile technology the space suit is being also developed . And behind this reason there have the numerous contributions of textile engineers.

(392)