Chenille Fibre | Advantages & Disadvantages of Chenille Fibres

Chenille Fibre:

Chenille may refer to either a type of yarn or fabric made from it. Chenille is the French word for caterpillar whose fur the yarn is supposed to resemble.

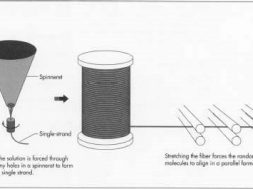

The chenille yarn is manufactured by placing short lengths of yarn, called the “pile”, between two “core yarns” and then twisting the yarn together. The edges of these piles then stand at right angles to the yarn’s core, giving chenille both its softness and its characteristic look. Chenille will look different in one direction compared to another, as the fibers catch the light differently. Chenille can appear iridescent without actually using iridescent fibers. The yarn is commonly manufactured from cotton, but can also be made using acrylic, rayon and olefin.

Many chenille fabrics should be dry cleaned. If hand or machine-washed, they should be machine-dried using low heat, or as a heavy textile, dried flat to avoid stretching, never hung.

Improvements :

One of the problems with chenille yarns is that the tufts can work loose and create bare fabric. This was resolved by using a low melt nylon in the core of the yarn and then autoclaving (steaming) the hanks of yarn to set the pile in place.

Chenille became popularized for apparel again with commercial production in the 1970’s.

Chenille yarn is primarily produced using cotton but use of acrylic, rayon, wool, silk and olefin is also fairly common. The chenille fabric made of 100% cotton is used to make shawls, blankets, throws, garments and other things owing to its incredible softness which is always desirable when making products that will be in close contact with the skin.

The method of manufacturing Chenille now is very different from when it was first produced in the 18th century. Chenille is made by placing short lengths of yarn between two “core yarns” and then twisting the yarn together. The wrapped yarns are cut to produce a pile effect. The edges of these piles then stand at right angles to the yarn’s core, adding to chenille’s softness. One of the problems with chenille is that the tufts can become loose resulting in bare fabric. This issue was resolved by using low melt nylon in the core of the yarn and then steaming the lengths of yarn to set the pile in place.

As the fibres catch light at different angles, chenille can appear iridescent even though no iridescent fibres are used.

Advantages of Chenille:

- Soft to the touch

- Has a good drape

- Slight sheen

- Thick and durable

- Water absorbent

- Resistant to abrasion

- Retains heat

- Multi-use fabric

Disadvantages of Chenille

- Fussier to maintain

- Prone to stretching and distortion

- Prone to shrinkage

(1112)