Modern Techniques of Weft Insertion in Projectile Weaving Machine

Modern Techniques of Weft Insertion in Projectile Weaving Machine

Conventional Weft insertion in Projectile weaving machine :-

To understand the modern techniques of weft insertion in projectile weaving machine first let’s see the weft insertion in conventional projectile machine.

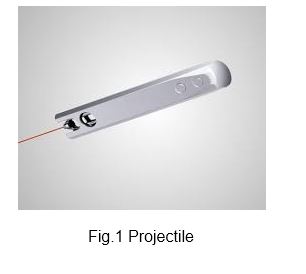

In conventional Projectile weaving machine a projectile (fig.1) is used to hold or grip the weft yarn and lay it in the opened shed. The projectile is having 10 times less mass than the shuttle used in shuttle loom. Due to this the weft is inserted at substantially higher speed. The projectile has clamps at one end which will hold the weft yarn.

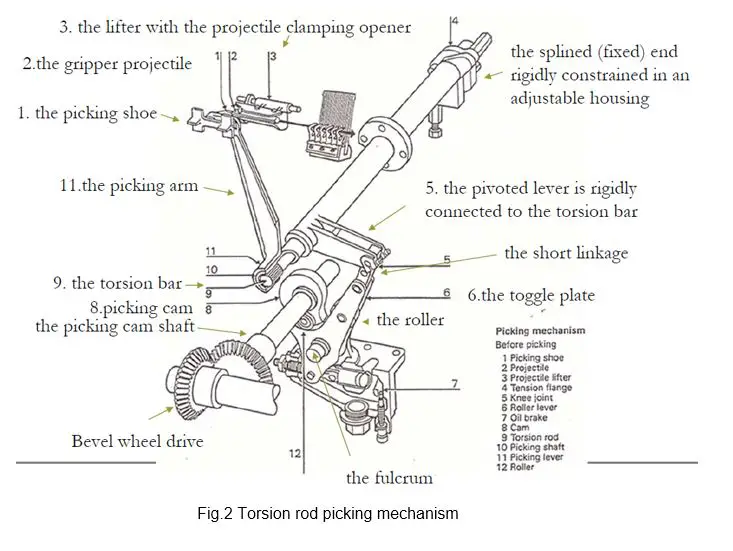

This projectile gets the motion due to the torsion rod picking mechanism (fig.2). In this mechanism the picking cam attached to the picking shaft which is getting the drive from the main shaft through bevel gear. This picking cam has the roller attached to it. Once the roller is in contact with the toggle plate, it gives the motion to plate. The toggle plate is further connected to the torsion rod with short linkage. The torsion rod is fixed at one end and another end is free to rotate around its axis. Due to the motion given to the toggle plate the torsion rod gets twisted since the opposite end is fixed. This torsion rod has the extraordinary properties to regain its original shape without any permanent deformation. Therefore once the roller attached to a picking cam is no longer in contact with the toggle plate suddenly the torsion rod gets untwisted with a lot of energy. This generated energy is then transferred to the projectile through a picking arm and picking shoe.

This projectile gets the motion due to the torsion rod picking mechanism (fig.2). In this mechanism the picking cam attached to the picking shaft which is getting the drive from the main shaft through bevel gear. This picking cam has the roller attached to it. Once the roller is in contact with the toggle plate, it gives the motion to plate. The toggle plate is further connected to the torsion rod with short linkage. The torsion rod is fixed at one end and another end is free to rotate around its axis. Due to the motion given to the toggle plate the torsion rod gets twisted since the opposite end is fixed. This torsion rod has the extraordinary properties to regain its original shape without any permanent deformation. Therefore once the roller attached to a picking cam is no longer in contact with the toggle plate suddenly the torsion rod gets untwisted with a lot of energy. This generated energy is then transferred to the projectile through a picking arm and picking shoe.

The main disadvantage of projectile weaving technique is that the energy utilization is not efficient than the shuttle loom. About 62% of the energy in the picking system is absorbed by the oil brakes (i.e. it gets wasted). This disadvantage is eliminated by the modern techniques of weft insertion in projectile weaving machine, along with some improvements in speed, productivity and flexibility.

Modern Weft insertion techniques in Projectile weaving machine:-

There are different types of weft insertion methods used in weaving. In conventional looms shuttle is used to carry and insert the weft in the warp sheet. In shuttleless looms different techniques are used such as Projectile, Rapier, Air jet and Water jet. During weft insertion in the weaving process, variety of demands needs to be fulfilled in respect to energy efficiency, productivity and flexibility to use all kinds of yarns. These demands are met only partially by the common methods of weft insertion.

There are different approaches made to fulfill these demands, but in this article we are only going to see the magnetic types of weft insertion. All the magnetic type of weft insertion techniques are based on the basic projectile type of weaving (i.e. use of projectile to carry the weft yarn). Mainly there are three methods used for magnetic weft insertion.

- Electromagnetic Projection

- Magnetic Timing Belt

- FOR-Maglev

1 . Electromagnetic Projection

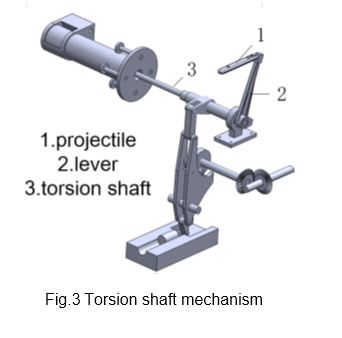

In the common projectile looms torsion shaft projection mechanism is used (fig.3). This mechanism has certain disadvantage on the matter of structure and efficiency. These disadvantages can be overcome by the electromagnetic projection technique.

The principle of Electromagnetic projection:-

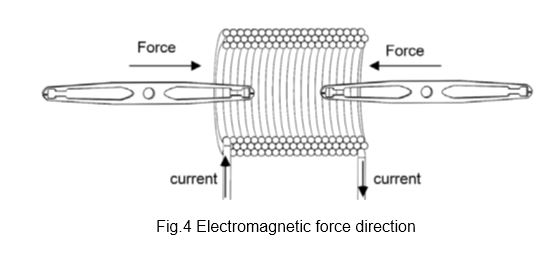

The basic principle of Electromagnetic projection is live conductor or ferromagnetic object in a magnetic field pushed forward by Electromagnetic force. Electromagnetic projection mechanism mainly consists of coils and projectile. Fig.4 shows the Electromagnetic force directions. When projectile comes in front of coil, Electromagnetic force pushes projectile move toward coil’s center and accelerate projectile.

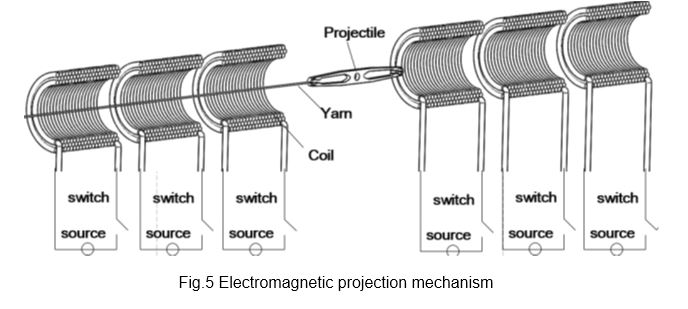

Electromagnetic projection model consist of power source, switches, coils and projectile, etc. As shown in fig 5. This mechanism using coil’s Electromagnetic force to accelerate projectile. Once the projectile moved to other side of the loom, the coils having reversed Electromagnetic force will apply brake to projectile and decelerate it. After projectile loaded with yarn, the Electromagnetic force will re-accelerate projectile, and repeat weft insertion process. Therefore this mechanism is bidirectional unlike the traditional projectile loom.

The traditional Projectile loom uses torsion bar and lever to impact on and accelerate projectile. After one projection process completed, the Hydraulic brake mechanism will apply brake to the projectile, and convey projectile to projectile conveyor belt to proceed for the next weft insertion process.

Compared to traditional Projectile loom, this mechanism omits the torsion shaft and its Transmission device, Hydraulic break mechanism, delivery mechanism, etc. Also reduces the impact and vibration of the whole mechanism, Simplified mechanical structure and improve the projectile loom’s reliability.

2 . Magnetic Timing Belt

This weft insertion technique is proposed by Jan Vincent Jordan, of RWTH Aachen University. As a prototype this technique is showcased at the ITMA 2015. He received the ITMA 2015 Research and Innovation Excellence Award for his work on this potentially influential new development.

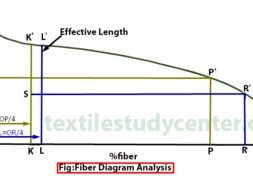

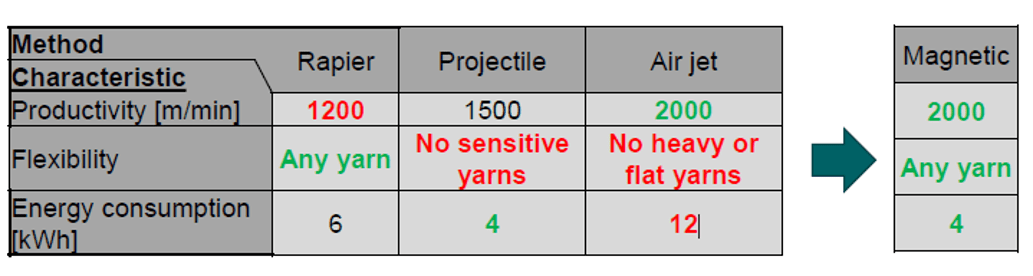

The highest productivity is currently achieved with air jet weaving, but at the same time energy consumption is also high, and there are limitations in terms of what yarns can be accommodated*. The globally-utilized weft insertion method that grants the highest productivity is the air jet system.

Meanwhile, Rapier weaving is the most flexible method, granting a gentle transport of any yarns, and with medium energy consumption, but also at lower speeds.

Projectile weaving has the lowest energy consumption of all, but due to the high acceleration at the initiation of movement, an impact load is put on the yarn that can only be bear by those with sufficient tensile strength.

Behind the development of the new magnetic weft insertion technique is the aim of combining the advantages of all three current commercial options – the highest speed, the lowest energy consumption and the ability to accommodate all yarn types.

*Newly manufactured airjets can accommodate the wide variety of yarns.

In functional tests, a proof of concept has been delivered, showing that the productivity of air jet weaving can be achieved at the low energy consumption of projectile weaving. In addition, completely new types of fabric can be manufactured with the magnetic insertion system – by alternating the movement of the weft yarn in the shed.

The promising magnetic weft insertion system developed at RWTH Aachen University

Mechanism of magnetic timing belt weft insertion:-

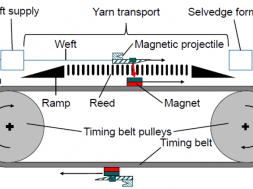

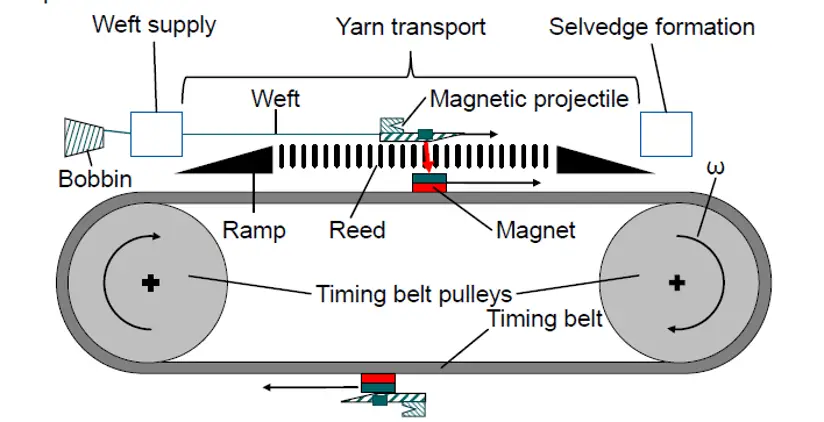

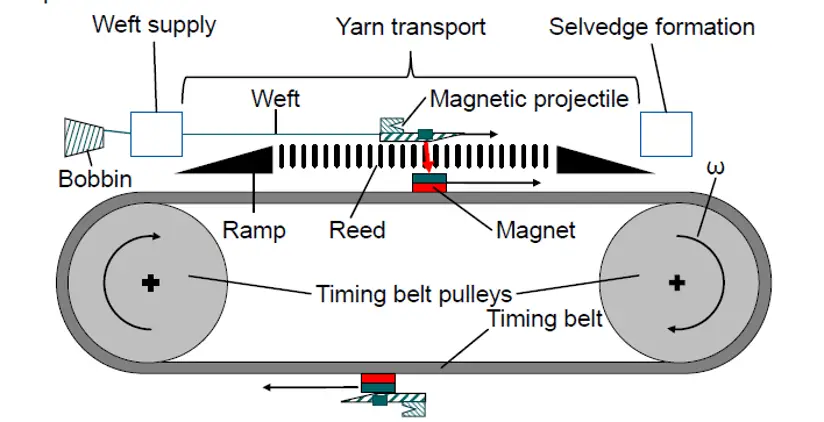

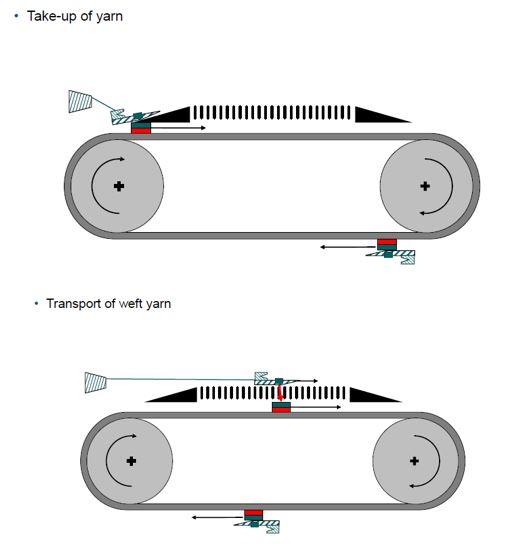

In this method two pulleys are placed below the area where shed is formed. On this pulleys timing belt is mounted. There are two permanent magnets attached to this belt at exact equal distance.

The permanent magnets on the belt attract the magnetic projectile and move it along the warp width over a specially made reed. Also on both sides of reed, ramps are placed so that projectile can go easily over the reed. Along with the magnetic projectile weft yarn is laid in between the shed.

Once the projectile reaches the other side of loom, it releases the weft yarn and beat up action takes place. All this processes are shown in the following figures –

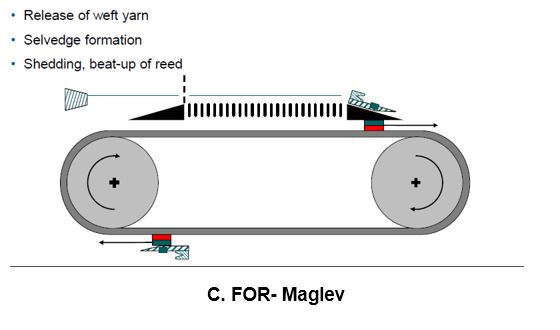

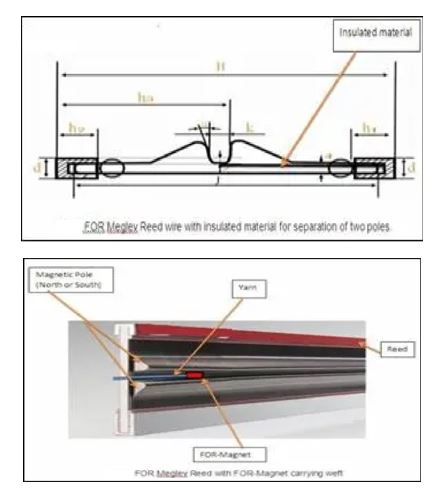

FOR-Maglev weft insertion is a transport system of weft yarn guided by magnet that uses magnetic levitation to suspend, guide and propel weft yarn. In FOR- Maglev insertion, levitating magnet carries weft yarn along a guide way of dents of reed by using magnetic force to create both lift and thrust. The power that is needed for levitation is not in particular a large percentage of the overall energy consumption; most of the used power is needed to overcome air resistance (drag), as with any other high-speed form of insertion.

This FOR-Maglev system can be attached to the airjet waving machine. Once we replace airjet system in the Loom with FOR-Maglev system, there is no need of air for weft insertion, which in turn, saves substantial amount of cost as there is no need of compressed air which is costlier source of energy. Even this device can be applied to other shuttle or shuttle less looms that work with the aid of shuttle, projectile or water. Further, with the use of this system it is possible to feed weft yarn from both sides (i.e. Bidirectional weft insertion)

3 . Mechanism of FOR-maglev:-

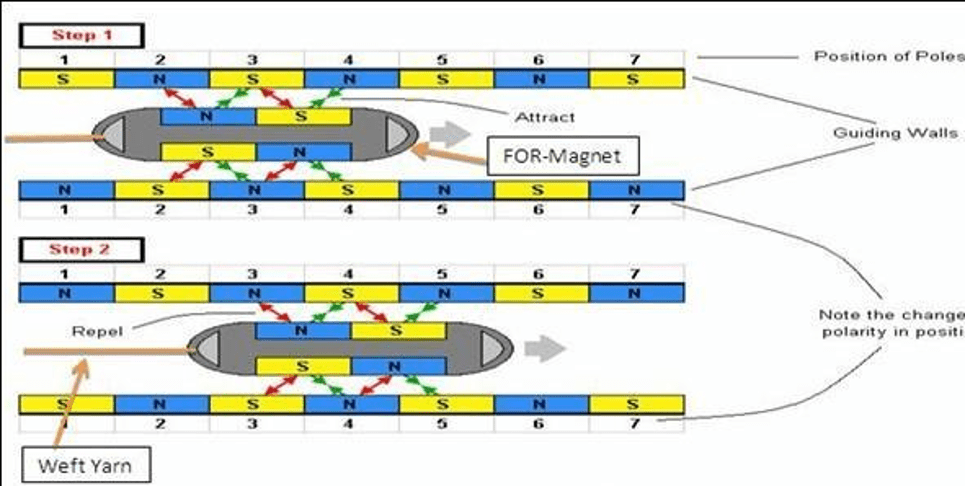

The basic concept of magnetism i.e. like poles repel and unlike poles attract, is the basic principle of Maglev. The electric current supplied to the coils in guide way walls is constantly alternating to change the polarity of the magnetized coil. This change in polarity is used to pull the Magnet forward and push from backside.

For the passage of FOR-Magnet projectile a special type of reed is required. The reed is equipped with magnetic poles which accelerates the projectile by constantly changing their polarity. The insulated material is fitted in the reed to separate the poles.

CONCLUSION:

All these types of magnetic weft insertion techniques are based on projectile type of weaving i.e. they all use projectile as a weft carrier. But the main difference between the conventional projectile weaving and magnetic weft insertion techniques is the mechanism which used to give the motion to projectile. The magnetic weft insertion techniques eliminate the disadvantages that were occurring in the conventional projectile weaving machines. One of the main disadvantage of projectile loom is the poor transferring of energy- only 14% of energy is transferred to the projectile from the torsion bar. Another disadvantage is the poor utilization of energy- about 62% of the projectile’s energy is wasted since break is applied on the projectile.

All these disadvantages are eliminated by the magnetic weft insertion techniques along with increase in productivity, less power consumption, low cost compared to similar productivity weaving machines (i.e. airjet).

REFRENCES:-

- Mechanism research and discussion for Electromagnetic projection bidirectional weft insertion Gripper Loom by Zhang Chi, Lei Xiaolong

- Development of Electromagnetic Picking System for Weaving Loom by Tharmarajah Thiruvaran

- Weft insertion via magnetic timing belt by Jan Vincent Jordan, Maximilian Kemper, Mario Gollasch

- Design and modeling of an electromagnetic launcher for weft insertion system by Abbas Mirjalili, Emad Owlia

- Study of a new Electromagnetic Weft Insertion Mechanism by Luo Sheng Mei, Zhang Bo

- Using Electromagnetic Force in Weft Insertion of Loom by Abbas Mirjalili

- Ballistic Weft Insertion by Prof. Dr. Emel Onder, Ass.Prof. Dr.Omer Berklp

- https://www.onlineclothingstudy.com/2015/11/itma-2015-sustainable-innovation-award.html

- https://www.fibre2fashion.com/industry-article/6113/air-jet-looms-can-run-without-air

- https://www.itma.com/media/the-itma-blog/blog-posts/blog/2015/11/18/technologies-in-transition-and-works-of-art

- http://www.indiantextilejournal.com/articles/FAdetails.asp?id=4557

(952)