Reactive Dyes – A Better Alternative To Traditional Dyes?

Reactive Dyes – A Better Alternative To Traditional Dyes?

How Is The Dyeing Operation Performed?

Dyeing operations are performed by binding dyes to fibres. There are primarily two types of dyes, namely:

- Water-soluble dyes

- Water-insoluble dyes

When it comes to dyeing fibres, some fibres adhere to and accept dyes easily, while others do not. Depending on the purpose you are seeking to achieve by dyeing, the fabric, and the type of dye you are planning to use make an immense difference in the process.

What Are Reactive Dyes?

Reactive dyes were primarily utilized for dyeing cellulose fibres such as cotton and viscose, but now, reactive dyes are being utilized in the dyeing of wool and polyamide as well. The range of available reactive dyes (whether in terms of chemical composition or in terms of the colour range they offer) is huge. They also enable an incredibly wide range of dyeing techniques that can be utilized for the purpose of dying. They first appeared commercially in 1956 and were invented in 1954. They are known by different trade names depending on the manufacturer and the country producing them Reactive dye manufacturers synthesize the dye through a chemical reaction of colour and reactive components.

The primary aspect of the difference between nature and reactive dyes is their resistance to water, reactivity during the dyeing process, and the variety of colours that they offer. This difference is primarily due to the difference in the chemical properties between chemical dyes and natural dyes. In recent times, reactive dyes have been made even better due to the development of certain chemical properties that increase their reactivity to cellulose, and have also become more soluble in water.

Which Are The Fibres That I Can Dye Effectively With Reactive Dyes?

The following fibres adhere to reactive dyes very effectively. They are:

- Natural fibres such as cotton, flax, and other cellulose-based fibres.

- Wool and Polyamide fibres.

- Silk and Acetate Fibres.

Reactive dyes are perhaps the most common types of dyes throughout the world in terms of their use. Especially when it comes to dyeing natural fibres, reactive dyes play a huge and advantageous role in ensuring that the dye adheres to the fibre. Reactive dyes happen to be the only class of dyes which make covalent bonds with the fibre and adhere to it in an extremely effective manner. They have a number of interesting properties.

Some of them are as follows:

- They are water-soluble to a large extent.

- They have incredible substantivity.

- They are able to form strong covalent bonds with the fibre.

- They have a wide range of colours.

- They are anionic in nature.

- They are cheaper compared to other types of dyes.

What are the chemical auxiliaries used in the process of dyeing cellulose fibres with reactive dyes?

There are a number of chemicals and auxiliary compounds used in the reactive dye manufacturing process with cellulose. Some of the chemicals that reactive dyes manufacturers use are as follows:

- Alkali materials such as sodium carbonate, sodium bicarbonate, and caustic soda.

- Salt

- Urea for the padding liquor in the continuous process

- Sodium silicate, in certain circumstances.

Reactive dye is only dye that reacts with the textile fibre & makes covalent with fibre.Under the suitable condition it reacts with –OH or –NH2 fibre & form covalent dye substrate linkage.

DYE-SO2-CH2-OSO3Na + HO-Cell —— D-SO2-CH2-CH2-O-Cell + NaHSO3

How Are Reactive Dyes Classified?

The following is the main classification of reactive dyes in terms of their chemical composition. They are:

- Chlorotriazine Dyes (MCT)

- Vinyl Sulphonyl Dyes (VS)

- Heterocyclic Halogen Containing Dyes (HHC)

- Mixed Dyes (MCT- VS)

Reactive dyes can also be classified on the basis of their application methods or temperature. They are primarily divided into cold brand reactive dyes, applied under extremely low temperatures (such as temperatures between 25-50 degrees C). The other two types are medium brand reactive dyes, which has a slightly higher application temperature ranging from 40-60 degree Celsius, and low brand reactive dyes, where the dyeing is carried out between 60-90 degree Celsius.

Cold brand reactive dyes are the most effective in terms of their adherence to the fibre. Reactive dyes also have a very good lightfastness rating of about 6. They are very stable in terms of electron arrangement and can protect the fibre against the degrading effects of ultra-violet rays. They also possess extremely good perspiration fastness with a rating of about 4-6.

What Are The Steps In The Dyeing Process?

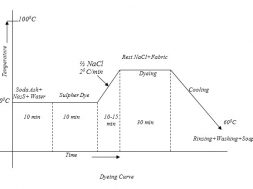

The following are the main steps in the dyeing process.

Dye absorption:

This refers to the immersion of fibre in the dye liquor, a process in which an electrolyte is added to assist the adherence of the dye. Various electrolytes (usually Sodium Chloride) is added.

Fixation:

This refers to the reaction of the reactive groups of the dye with the groups of the fibre forming a strong covalent bond and ensuring adequate and proper adherence.

Wash Off:

Undoubtedly, this is also an important step when it comes to reactive dyes as the excess and unwanted material must be washed off and removed from the surface of the fibre.

Due to all these reasons, reactive dyes are an extremely good option.

(266)