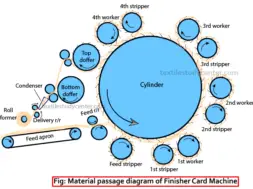

Finisher Card Machine

Study on material passage diagram of Finisher Card machine.

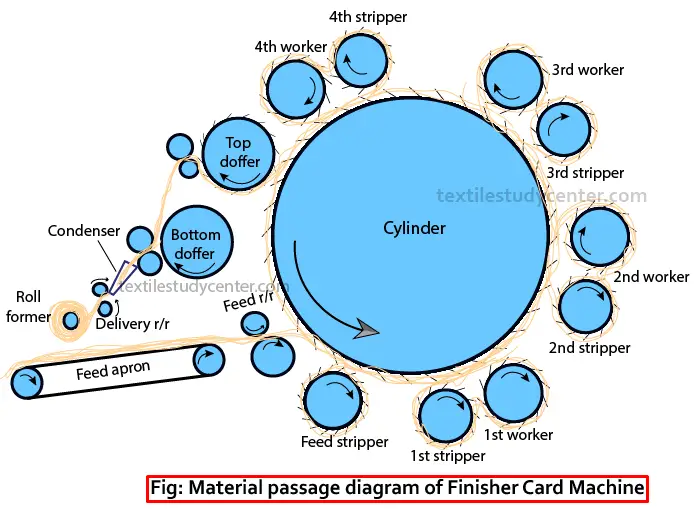

Introduction: For getting better quality of jute yarn, Finisher card machine is necessary for jute spinning industry. It is usually down striking and full circular carding machine, having 4.5 pairs of workers and strippers. Its feed and delivery is on the same side of the machine. A number of breaker slivers are feed side of the Finisher card to obtain a more uniform sliver from it and to mix different qualities of fiber.

Objectives:

To Split up & Break down the jute fiber.

To individualize & parallelize the jute fibers.

To straighten the jute fibers.

To remove trash from jute fibers.

To blend different grades and varieties of jute

To blend jute with others fibers like wool, stapled rayon, etc.

Input: Breaker carded sliver

Output: Finisher carded sliver

Main Parts:

- Motor

- Motor shaft

- Feed sheet

- Feed roller

- Pin feed roller

- A big Cylinder

- Feed stripper roller

- Stripper (4 pair)

- Worker (4 pair)

- Doffer (2pair)

- Drawing roller

- Drawing press roller

- Condenser

- Delivery roller

- Delivery press roller

- Roll former

Working Principle of Finisher Card Jute Carding Machine:

The total working procedure of a finisher card jute carding machine has explained in the below:

① 10-12 breaker card slivers are placed at the fed end of the finisher card side by side.

② Two types of feed systems like the shell feed and double pinned fed system.

③ Shell fed system is used for sacking weft cards and light card loading is possible in double pinned feed.

④ Pin feed roller and feed stripper both have pins so little amount of carding action takes place when fibres come in contact with the top feed roller, pin feed roller and feed stripper.

⑤ Carding action takes place when fibres are transferred to the worker.Here cylinder and worker pin direction is opposite and cylinder speed is much higher than the worker stripper.

⑥ Here the fibres are attenuated and individualized.

⑦ The same action is repeated along the 2nd, 3rd and 4th pair of worker and stripper.

⑧ Doffing action takes place when fibres are about to leave the 4th worker stripper and here the pin derection of doffer and cylinder is opposite.

⑨ Then the fibres pass through the drawing roller to 2nd doffer to drawing roller to delivery roller.

⑩ The finished sliver is condensed to the delivery in roll form finally.

Conclusion:

Finisher card is important step in high quality jute yarn production. It makes the jute fibers more straight and parallel through action of 4.5 pair of roller.

(3785)