Laser Technology: Paving the Way for Sustainable Denim Washing

The global demand for denim continues to rise, particularly among the younger generation who prefer washed, faded, and distressed jeans over solid-color denim. However, traditional denim washing techniques consume vast amounts of water and chemicals, posing significant environmental challenges. With growing concerns over global warming and ecological hazards, the fashion industry is shifting towards sustainable alternatives. One of the most revolutionary advancements in this field is the adoption of laser technology, which reduces water and chemical usage while enhancing efficiency in denim processing.

The Environmental Impact of Traditional Denim Washing

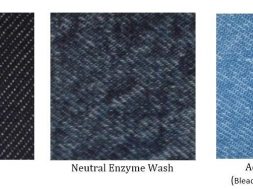

Conventional denim washing methods involve various processes such as potassium permanganate (PP) spray, bleaching, acid washing, stone washing, enzyme washing, and hand sanding. These techniques require significant amounts of water and chemicals, leading to water pollution and resource depletion. In an industry where sustainability is becoming a critical concern, adopting innovative technologies such as laser washing is a game-changer.

How Laser Technology Works in Denim Washing

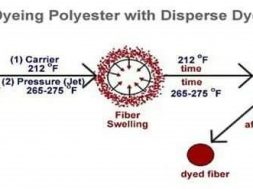

Laser technology acts as a thermal source to evaporate indigo dye from denim fabrics, using CO2 and DC current instead of Potassium Permanganate spray.

The Laser machine has three parts:

- the computer part,

- the Siler part, and

- the Laser part.

The work-bed can be a honeycomb structure, metal salts, or rods. Fabrics must be at least 98% cotton, as polyester is difficult to use with Laser. Indigo fabric works well.

Laser working sequences

- Create the design pattern on a computer using graphics editing software and convert it to a grey scale.

- Input the design file into the Laser system and set parameters for pixel time and resolution.

- Place the garments on the honeycomb cutting table, identify the Laser engraving area, and conduct Laser engraving.

- The Laser burns the fabric surface.

- Fume extraction from below the workpiece enables gases to circulate and debris to be removed from the work area.

Sustainable Advantages of Laser Technology

- Water Conservation : Traditional denim washing processes use approximately 70 liters of water per pair of jeans. Laser technology eliminates the need for water-intensive treatments, reducing water usage by up to 67%.

- Reduction in Chemical Usage : Chemical treatments such as PP spray and bleaching contribute to pollution and worker health hazards. Laser technology eliminates or significantly reduces the need for these harmful chemicals, making denim processing safer and more sustainable.

- Energy Efficiency : Laser technology consumes 62% less energy than conventional denim finishing processes. The reduced need for repeated washing cycles also contributes to lower energy consumption.

- Increased Production Efficiency : Compared to manual scraping, which produces 10 pairs of jeans per hour, laser machines can process up to 200 pairs per hour. This increased efficiency reduces labor intensity while maintaining design precision.

- Worker Safety and Well-being : Traditional denim finishing methods, such as sandblasting, expose workers to harmful silica dust, increasing the risk of lung diseases like silicosis. Laser technology eliminates this risk, providing a safer working environment.

Complementary Sustainable Technologies

Besides laser technology, other green innovations in denim washing include:

- Ozone Fading: Uses ozone gas instead of chemicals for bleaching, reducing water and energy usage.

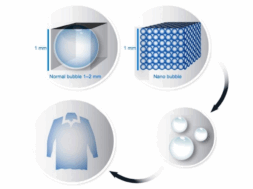

- E-Flow Technology: Generates nano-bubbles to distribute finishing agents more efficiently, saving water and chemicals.

(155)