Acid wash | Random wash | Acid Wash by Stones

Acid wash / Random wash

At present times, the most popular denim garments are random washed among the fashionable people. When solid washed the fading, effects are even and uniform in the garments but when random washed effects are uneven.

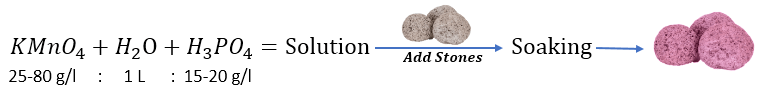

The first step of acid wash is rinse if needed then desized by enzyme (alpha amylase ) or by desizing chemicals according to the fabric of the garment. Then wash by cellulosic enzymes if needed to bring abrasion effects. After that random wash procedures starts by making potassium per manganate (KMnO4)or bleach ( NaOCl ) solution with required amount of water or phosphorous acid and uneven effect making elements like stones, balls, towels and thermopols. To bring random effects on garments must be wet so the garments should be hydro extracted before throwing to the belly machine.

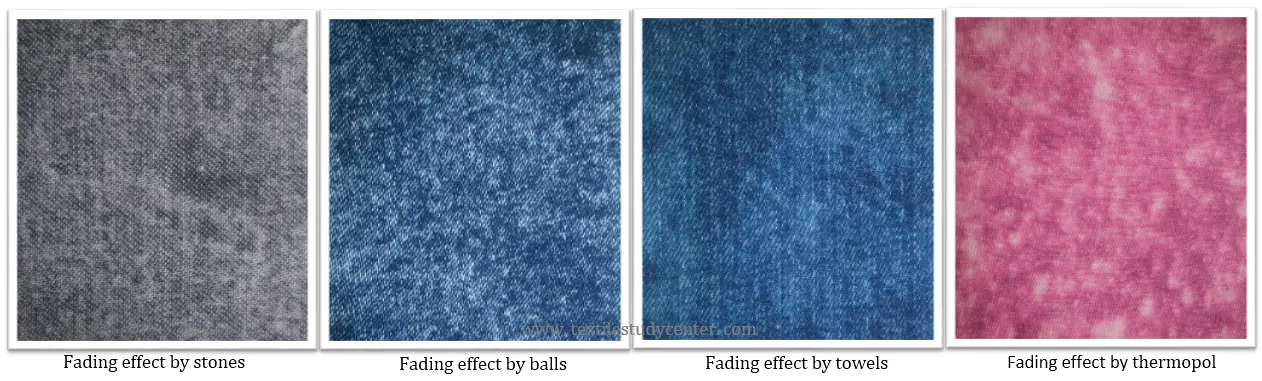

Various types of effects can be produced by following elements are given below:

- Pumice Stones: Makes small fading effects like drop of pin point on the surface of the garments.

- Balls: circular and small line fading effects

- Towels: big uneven fading effect like sweeping randomly

- Thermopols: Random sized fading effect sometimes looks like lengthwise fading

Acid Wash by Stones :

At first pumice stones must be soaked by solution of strong oxidizing agents like sodium hypochlorite ( 5-10% ) (NaOCl) or potassium permanganate (KMnO4) (3-6% ). Excess liquor is removed from the stones. Certain amount of treated stones and garments is dry tumbled in the belly washing machine to bring the desired random effects on the garments is called acid washing or snow washing or ice washing,

Stones can be treated by two ways like –

1. Stones are taken into a net or mesh fabric and soaked into the solution then dried on air.

2. An excess piece of fabric is placed into the belly machine, then stones are gathered on the fabric and the solution is sprayed on those stones and run the machine for 2-3 mins by tumbling to remove excess solution and also to mix them properly.

The soaked stones and wetted garments are loaded into the belly machine. According to the desired fading effect, the machine is tumbled 2-10 mins. The degree of color fading depends on the stone ratio, concentration of the chemicals, types of garments and dyestuff’s. After getting the desired effect, the garments are loaded on another machine for rinse for 3-4 mins. As KMnO4 or NaOCl are hazardous chemical so neutralization is mandatory for further processing. If KMnO4 is used then MnO2 is formed which leads to brown / orange tone and must be removed by oxalic acid and if NaOCl is used then a reducing agent like sodium bisulphite is used for neutralization. Finally the garment treated with softener, hydro extracted and dried by dryer.

Acid wash | Random wash | Acid Wash by Stones

Steps of Acid washing:

Process flowchart :

Step 01: Desizing

Water is added ( Let, M:L = 1:60 )

↓

Loading garments

↓

Machine started running

↓

Desizing chemicals added ( let, 2 g/L )

↓

Antibackstainer added ( .5 g/L )

↓

Pumice Stone added if needed ( Let , 5 Kg)

↓

Steam to raise temp 60°C

↓

Process time 10 minutes

↓

Drop liquor

↓

Rinse 2X

Step 02: Enzyme Wash

Water is added ( Let, M:L = 1:60 )

↓

Machine started running

↓

Neutral Enzyme added ( let, 3 g/L )

↓

Antibackstainer added ( .5 g/L )

↓

Pumice Stone added ( Let , 10 Kg)

↓

Steam to raise temp 50°C

↓

Process time 40 minutes

↓

Drop liquor

↓

Hydro-extraction ( 3 mins ) not dry

Step 03: Acid / Random Wash

Hydro-extracted garments loading

↓

Spread out treated stones in the machine

↓

Dry tumble for 4-5 mins

↓

Check effect ( if ok )

↓

Neutralization

↓

Overall bleach if needed ( 4 min , 50oc )

↓

Neutralization

↓

Softening

↓

Hydro extraction

↓

Drying

↓

Quality Check & Delivery

(2494)