Wool Fibre | Manufacturing Process of Wool Fibre | Part 02

Part 01: Wool Fibre | Wool Fibre Identification | Uses & Application of Wool fibre

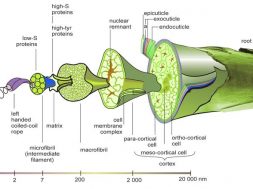

Part 03:Wool Fibre Morphology | The Macro Structure of Wool

Part 04: Physical & Chemical Properties of Wool Fibre

Wool Fibre | Manufacturing Process of Wool Fibre | Grading System of Wool Fibre

Wool Fibre:

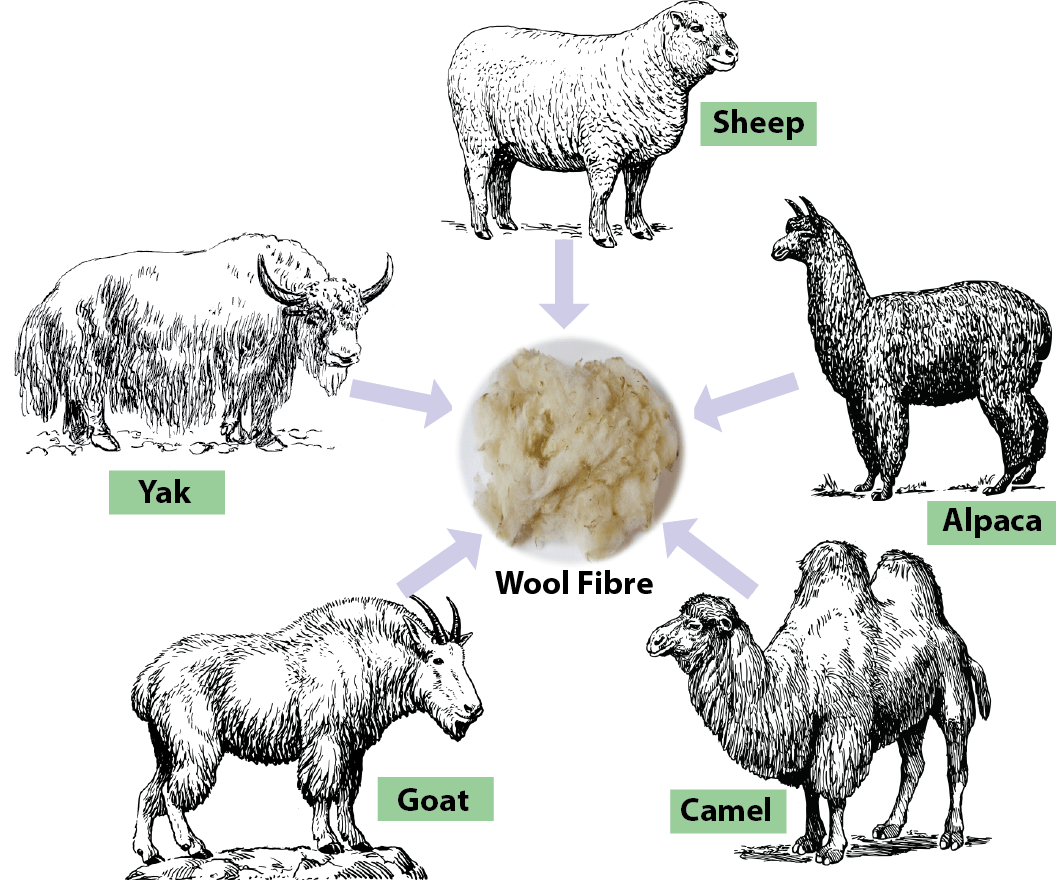

Wool is the natural protein fibre obtained from sheep and certain other animals, including cashmere from goats, mohair from goats, angora from rabbits, and other types of wool from camel. It is a multi-cellular, staple fibre. The density of fibre is 1.31g/cc, which is tends to make wool a medium weight fibre.

Fig: Source of Wool

Manufacturing Process of Wool Fibre:

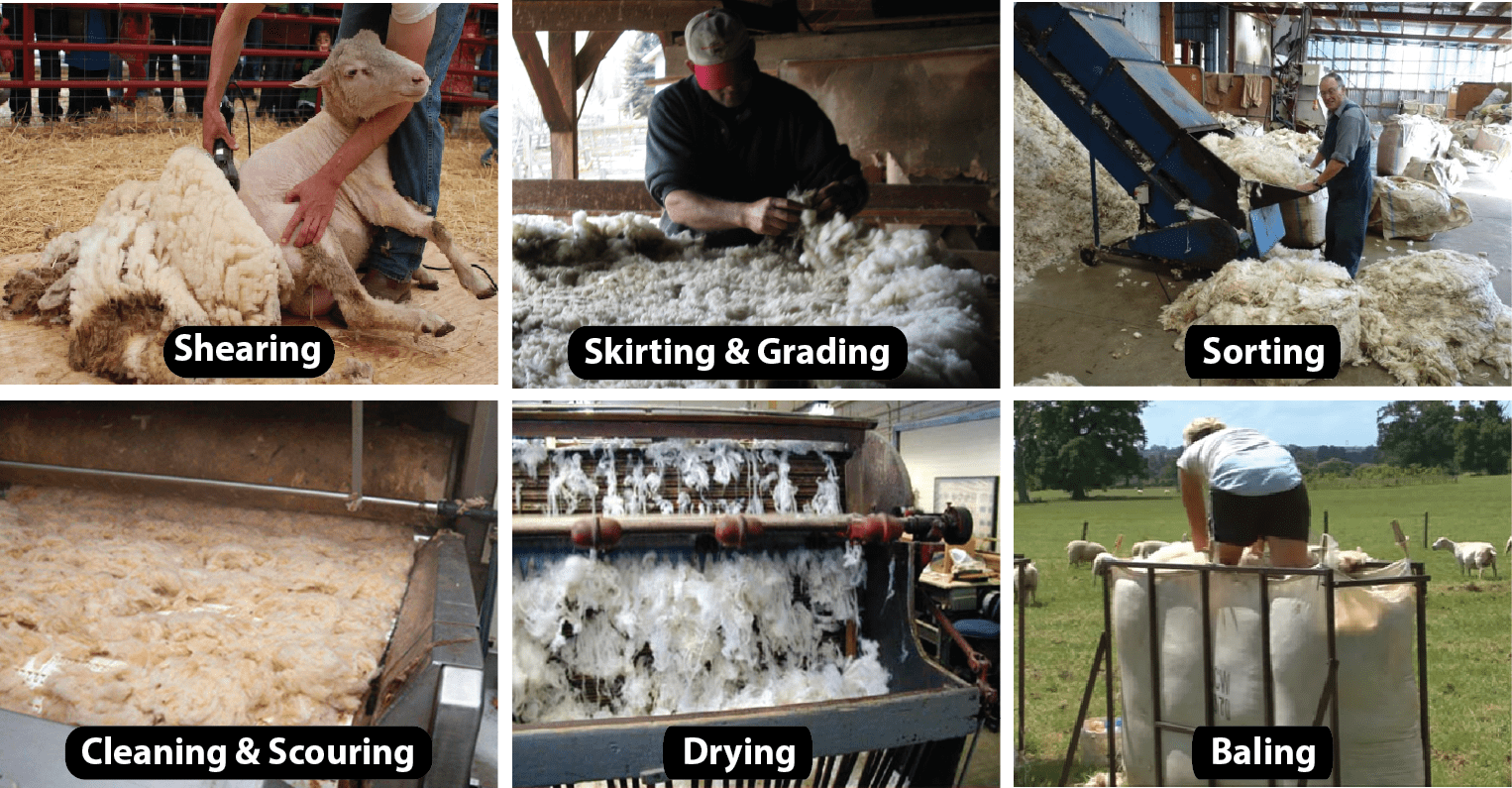

Shearing:

Sheep shearing is the process by which the woolen fleece of a sheep is cut off. The person who removes the sheep’s wool is call shearer.

Generally, each adult sheep is shorn once each year (a sheep may be said to have been “shorn” or “sheared”, depending upon dialect).

Sheep are sheared once a year – usually in the springtime. A veteran shearer can shear up to two hundred sheep per day. The fleece recovered from a sheep can weigh between 6 and 18 pounds; as much as possible, the fleece is kept in one piece. While most sheep are still sheared by hand, new technologies have been developed that use computers and sensor, robot-controlled arms to do the clipping.

Skirting:

Skirting is the practice of separating all inferior fleece portions (head, lower leg and belly wool) and any urine and contaminated fibres from the rest of the fleece at shearing. The products of skirting are termed skirted wool and skirts. Since large variations exist among skirts from different body areas, these should be packaged separately for technical and economic reasons.

- Wool from the top of the head, jaw, and cheeks tends to be short and sometimes heavily contaminated with vegetable matter.

- Belly wool is usually lower yielding and may be either finer or coarser than the bulk of the fleece. It also tends to contain more vegetable and colored fibre contamination than the bulk of the fleece.

- Lower leg wool is short and tends to be composed predominantly of medullated(coarse) hair fibres. The fibres in this skirt are variable in length, and scouring these fibres results in a relatively low yield of low quality of wool.

Since the term skirting generally implies removal of all wool that does not match the bulk of the fleece, short wool, matted pieces, paint, skin pieces, areas of the fleece heavily contaminated with vegetable matter, and specially colored wool all fail into skirts category.

Grading:

Wool fleeces differ in many measurable characteristics:

- Fineness,

- Yield,

- Length,

- Strength,

- Color and

- Vegetable matter contamination.

When fleeces are grouped according to any or all of these characteristics, the process is called grading. This is determined either by the experienced Graders or by the prospective buyers themselves who take the samples for the purpose. Graders can do the job simply through visual inspection. Fine and medium wools having longer staple lengths if more than three inches are considered to be of good quality and are used for making light – weight worsted suit and dress fabrics. Coarser and short staples of less than three inches long are used for making bulky sweater and carpet yarns.

In the United States wool is graded using three methods:

1 . The “American” or “Blood” System: This is an older system where wool is graded depending upon the amount or percentage of “fine wool” sheep breeding (Merino/Rambouillet blood) there is in the animal being shorn.

2 . The “British “ ,”Bradford”, or “Spinning Count “ System: This is based on the amount of “Hanks” of yarn that can be spun from 1 pound of scoured (washed) wool. One Hank=500 yards of yarn. If a Rambouillet grades 64s (fine grade), then 1 pound of clean wool from that sheep will yield over 20 miles of yarn (64*560 yards of yarn). This system’s grade numbers are always even numbers, with the lowest being 36s and the highest 120s. With this system the larger number will be a finer wool.

3 . The Micron System: Increased emphasis on an exact and highly descripted method of describing woo; grade has produced a measuring system in which individual fibres are accurately measured. The unit of measure is the micron, which is one millionth of a meter or 1/25,000 of an inch. Fineness is expressed as the mean fibre diameter. Eventually, this system will become the standard for describing wool in the United States.

Sorting Technique of English Wool:

When individual fleeces are subdivided again according to any or all of the above characteristics, the process is called sorting. Sorting requires more skill than grading or skirting. Because of the level of skill that is required, sorting is usually a function performed by a specialized wool deal or the textile firm itself.

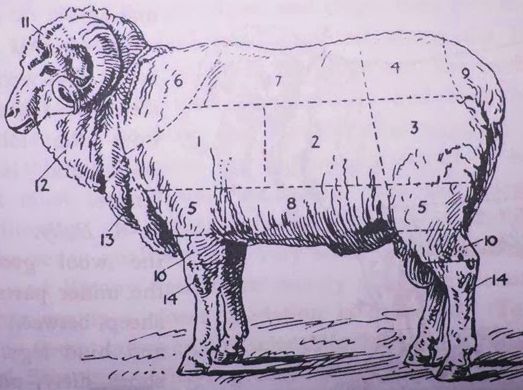

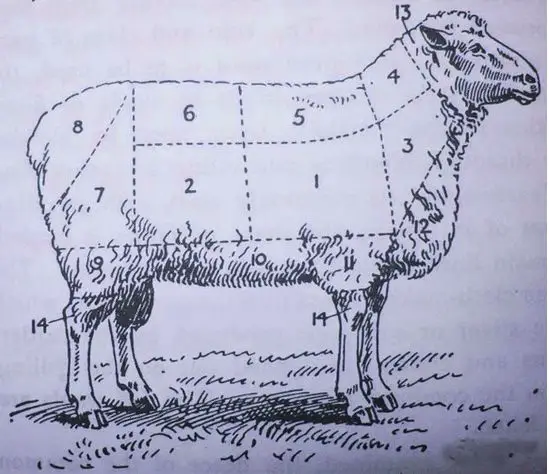

Figure: English Wool Sorting (Leicester Ram)

Figure: English Wool Sorting (Leicester Ram)

For those manufactures who desire to grade their wools finely the fleece of the common sheep has been carefully mapped out as follows, the lowest numbers denoting the highest qualities –

1. Shoulder: Long and fine wool, growing close and even.

2. Side: Stronger, but otherwise equally good.

3. Neck: Short, but fine, liable, to be mixed with grayish wool near the head.

4. Back of neck: Inferior to first three.

5. Top of fore shoulder: Faulty and irregular, but of fair medium quality.

6. Lions and back: Rather coarse and short.

7. Middle of haunch: Long, strong wool of large staple, grading from fine to coarse.

8. Hinder parts: Coarse and long, apt to be hairy.

9. Top of hind legs: Very like 7, but rather dirtier.

10. Under body: Short, dirty, fine towards the fore legs. A tender wool, and known as ‘broke’.

11. Top of fore legs: Short and fine.

12. Throat: Irregular, short, and kemp; very often full of grass and fodder.

13. Head: Short, rough and coarse wool.

14. Shanks: Rough, hard wool; very short and of little value.

Sorting Technique of Merino Fleece:

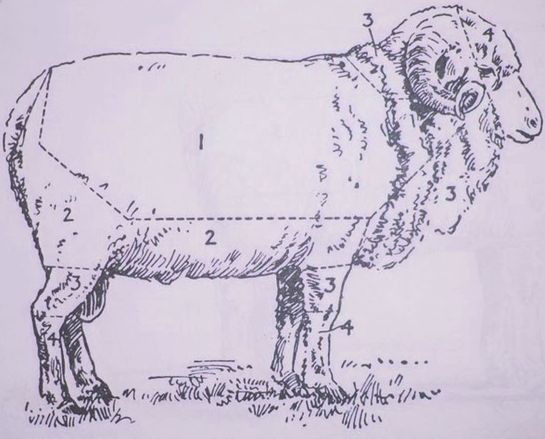

Figure: Merino Wool Sorting (Merino Ram)

The merino sheep produces the finest of all wools, and the fleece has been finely graded by Dr. Bowman in this manner –

1. Shoulders: The wools grown on these parts are commonly the best in the fleece, being specially strong and long in staple, soft in texture and uniform in character.

2. Sides: Same as shoulders.

3. Lower part of back: This is also wool of good, sound quality, resembling in staple that obtained from the shoulders and sides, but not so soft and fine in fibre.

4. Loin and back: The staple here is comparatively shorter and the hair not so fine.

5. Upper parts of legs: Wool from these parts is of a moderate length but coarse in fibre. It is generally sound, but liable to contain some vegetable matter.

6. Upper portion of neck: The staple of the wool clipped from this part of the neck is wholly of an inferior quality, being faulty and irregular in growth, as well as full of thorns, twigs, grass and other matters.

7. Central part of back: This wool closely resembles that obtained from the loins and back, and is rather tender.

8. Belly: This is the wool grown on the under parts of the sheep, between the fore and hind legs. It is short, dirty and poor in quality, and somewhat tender.

9. Root of tail: Fibre coarse, short and glossy, and very often the wool is mixed with kemps or dead hairs.

10. Lower parts of legs: Most of the wool grown on these parts is dirty, greasy, and rough, the staple lacking curliness and the fibre fineness. It is usually full of burrs and vegetable matters.

11. Head: The wools from the part is stiff, straight, coarse, mixed with fodder and kemps.

12. Throat: Same as head.

13. Chest: Same as head.

14. Shins: The wool from the shins is short, straight and stiff and of small textile value.

In Sorting, the wool is broken up into sections of different quality fibres, from different parts of the body. The best quality of wool comes from the shoulders and sides of the sheep and is used for clothing; the lesser quality comes from the lower legs and is used to make rugs.

Sorting Technique of Spanish Wool:

The merino fleece is generally divided by the Spaniards into four sections –

1. Refina: Extending from the lower jaw down to the fore shoulder, across to the haunch, curving round to the back above the tail.

2. Fina: Taken from the belly, hind quarters, and upper thighs.

3. Tercina: Short wool taken from the head, throat, lower part of the neck and shoulders, ending at the joint.

4. Inferior: From forehead, cheeks, tail, and legs.

Cleaning and Scouring

Wool taken directly from the sheep is called” raw” or “grease wool”. It contains sand, dirt, grease, and dried sweat. The weight of these contaminants accounts for about 30 to 70 percent of the fleece’s total weight. Wool scouring machine contains warm water, soap, and a mild solution of soda ash or other alkali. They are equipped with automatic rakes, which stir the wool. Rollers between the vats squeeze out the water. If the raw wool is not sufficiently clear of vegetable substance after scouring, it is put through the carbonizing bath of dilute sulfuric acid or hydrochloric acid to burn out the foreign matter.

Drying:

Wool after scouring should not be allowed to become absolutely dry. About, 12 to 16 percent of the moisture is left in the wool which would enable handling of the fibres in further processing.

Bailing of wool:

A wool bale is a standard sized and weighted pack of classed wool compressed by mechanical means of a wool press. This is the regulation required method of packaging for wool, to keep it uncontaminated and readily identifiable. A “bale of wool” is also the standard trading unit for the wool on the wholesale national and international markets. Each bale contains 330kg (778 lbs.) of graded wool (approx. 110 fleeces), wrapped in plastic and tied by wire.

Dimensons: 109cm x 71cm x 104 cm

Part 01: Wool Fibre | Wool Fibre Identification | Uses & Application of Wool fibre

Part 03:Wool Fibre Morphology | The Macro Structure of Wool

Part 04: Physical & Chemical Properties of Wool Fibre

(5112)