Natural Color Substances for Textile Materials

Natural Color Substances for Textile Materials

EXPLORATION TEHNIQUE NATURAL DYES SUBSTANCE OF PLANTS IN AROUND US FOR DYEING TEXTILE MATERIALS

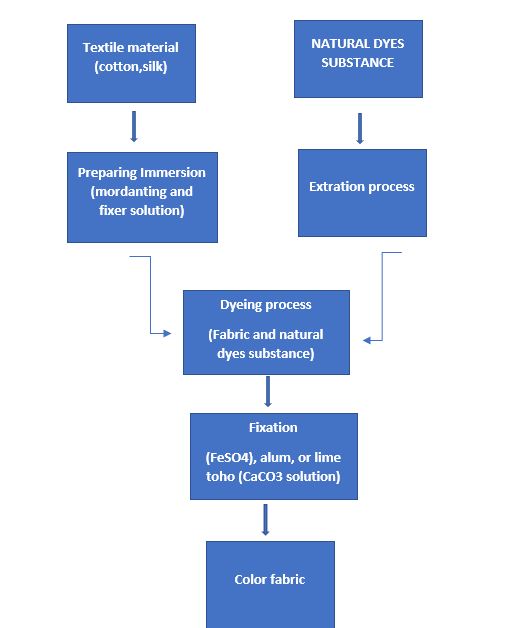

According to the source of the textile dye is classified into 2, namely:

First, Natural Coloring Agent (NCA) is a dye derived from natural materials in generally from the extracts of plants or animals. Second, Substance Synthesis Agent (SSA) is Artificial color or synthesis is made by chemical reaction with a stone charcoal base coal material or petroleum which is the result of such aromatic hydrocarbon derived compounds benzene, naphthalene and anthracene

In the beginning the process of coloring textiles using natural dyes. However, technological advances along with the discovery of synthetic dye for textiles, the more eroded the use of natural dyes.

Fashion design that uses natural dyes have a selling value or a high economic value because it has artistic value and distinctive color, environmentally friendly so impressive ethnic and exclusive.

Natural Color Substances for Textile Materials:

Natural dyes for textile materials are generally obtained from extracts various parts of plants such as roots, wood, leaves, seeds or flowers. such as: tilapia tree (indofera), bark of soga tingi tree (Ceriops candolleanaarn), timber tegeran (Cudraina javanensis), turmeric (Curcuma), tea (The), roots mengkudu (Morinda citrifelia), soga jambal skin (Pelthophorum ferruginum), kesumba (Bixa orelana), guava leaf (Psidium guajava).

Textile materials dyed with natural dyes are the ingredients derived from natural fibers such as silk, wool and cotton.

Exploration of Natural Color Substances and Dyeing Technique:

most of the colors can be obtained from plant products, in the plant tissue there is plant pigment Different color schemes depend on their chemical structure. The pigment plants can be chlorophyll, carotenoids, flovonoids and quinones. For that pigment – Such natural pigments need to be explored from plant tissue or organs and made into solution natural dyes for dyeing of textile materials. The exploration process is done by extraction technique with water solvent. The chemicals used are tunjung (FeSO4), alum, sodium carbonate / soda ash (Na2CO3), calcium oxide (CaCO3),

Natural Dyes Extraction Process:

In the process of extraction / preparation of natural dye solution needs to be adjusted with the weight of the material to be processed so that the amount of the natural dye solution is produced can be sufficient to dye the textile material. Number of natural dye solution which depends on the amount of textile material to be processed. Comparison of solution dye with textile materials commonly used is 1: 30. For example, the weight of textile materials which is processed 100 grams then the need of natural dye solution is 3 liters.

The following is measures extraction process to explore natural dye in a scale laboratory

- Cut into small size – a small part of the plant you want, for example: leaves, stems, skin or fruit. Materials can be dried first or direct extracted. Take the piece weighing 500 gr.

- Insert the pieces into the pan. Add water with comparison 1:10. For example if the weight of the material extracted 500gr then the water 5 liter.

- Boil the ingredients until the water volume becomes half (2.5liter). If desired dye solution so thicker the volume of residual boiling can be reduced for example to one-third. As an indication that the color pigment is inside plants have come out shown with water after boiling into color. If the solution remains clear then the plant is almost certainly not contains color pigments.

- Filter with the filter solution screen the extraction process results to separating with the remaining material extracted (residue). Solution extract the results This filtering is called a natural dye solution. After chilling the solution is ready used.

Preparing Immersion With Natural Substances:

Before dipping with natural dye solution on cotton and silk fabrics it is necessary to do some preparation process as follows:

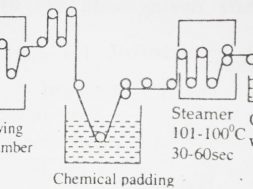

- Mordanting Process:

Textile materials to be colored must be processed mordanting first. Process This mordanting is intended to increase the appeal of natural dyes to the material textiles as well as useful for producing good color and sharpness of color.

Soak textile material to be colored in 2gr / liter neutral soap solution or TRO (Turkey Red Oil). This means that every 1 liter of water is used added 2 grams of neutral soap or TRO. Immersion done for 2 hours. Can also soaked overnight. After that the material is washed and aerated

- Preparation of fixer solution (color lock):

In the process of dyeing textile materials with natural dyes needed fixation process (Fixer) that the locking process colors after dyed material with natural dyes that color has good fastness. There are 3 types of fixer solution commonly used tunjung (FeSO4), alum, or lime tohor (CaCO3) .with the way: Dissolve 50 grams of tunjung (FeSO4), alum, or lime tohor (CaCO3 in each liter of water used. Let it settle and take the clear solution.

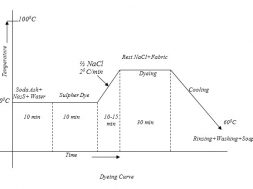

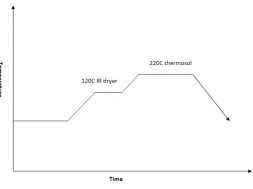

- Dyeing process With Natural Dyes:

After the material in mordanting and fixer solution is ready then the dyeing process of textile material can be done in the following way

- Prepare a solution of natural dyes extraction process results in dyeing place.

- Insert textile material that has been memordanting into the natural dye solution and processed immersion for 15 – 30 minutes

- Insert the material into the fixer solution. The material is processed in fixer solution for 10 minutes

- Rinse and wash the material and then dry. The material has been colored with solution natural dye.

(160)