Light Fastness and Factors Influencing Light Fastness Behavior

Light Fastness and Factors Influencing Light Fastness Behavior

MTextile Dyes and Pigments used in the industry vary to a great extent in terms of their resistance to light sources and this phenomenon is called as ‘Light-fastness of Textiles’. Sunlight materials emits electromagnetic radiations of several wavelengths. Visible range of spectrum (400 – 700 nm) , ultraviolet (300 – 400 nm) and infrared (700 – 1400 nm) become the main constituents which reach to the earth’s surface. Colored materials like Textile, Leather and Paper when subjected to the photons generated from the sunlight have tendency to destroy the coloring constituents of dyes and pigments. Further prolonged exposure may even cause destruction to the substrate itself. Partial destruction of the coloring material in dyes and pigment is known as fading.

The other detrimental effect could be change of tone or change of brilliance of the color. A consumer when buys an apparel is attracted to the colors and if this color is altering / fading during usage or laundering, the consumer gets frustrated, so it is responsibility of dyestuffs manufacturers to safeguard and guide the processor about the fading behavior of a dye/pigment applied on the substrate. There are many factors influencing the light fastness behavior.

- Substrate and their diffusion properties.

- Substrate preparation.

- Chemical nature of the fiber.

- Method of the application.

- Delusterants in the substrate.

- Finishing chemicals applied

- Usage of the article.

- Dye-fixers used.

- Choice of colors and their combination.

- Perspiration and exposure to light.

- Prolonged exposure to light.

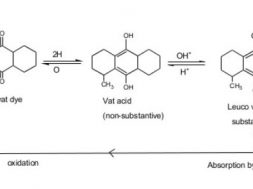

- Oxidative or reductive nature of dye fading reaction.

Unfortunately, the tag labels on articles do give wash instruction but the guidance and sustainability of the article to multiple exposures to light are not so popular. There are hardly any indicators to guide the consumer regarding the resistance of the article towards sunlight fading.

Uncontrollable Factors

- Content of UV amount in the sunlight: As more is the UV component more photons of their light and more will be the effect on color with respect to fading.

- The intensity of temperature from the sunlight falling on the article.

Relative Humidity

- Higher the humidity, higher could be fading.This factor has impact on the wet-light fastnessand hence fading in varying humid environments comes into the picture.

- Atmospheric contaminations.

- Amount and quality of perspiration also play acrucial role in deciding the amount of fading.

- Laundering pattern.

- Repeated laundering and exposure to sunlightor a single exposure to sunlight also affects thedegree of fading.

Some Guidelines

- Higher the depth, better the light fastness.

- Only right choice of colors can help in gettingbetter light fastness and any corrective actionswould fail to improve the light fastness.

- Right choice of textile chemicals to ensure thatno detrimental effects of them on the light fastness of dyed articles occur.

- When use of more than one color is made inmaking a shade, the final light fastness of thearticle will be based on the lowest light fastnessconstituent of the dye in the recipe. This is moreimportant when we want to ensure on-tonebehavior of fading after exposure to light (onecomponent fading to smaller extent will give afurther ugly appearance to the shade than one with on-tone fading).

High Light fastness reactive dyestuffs from renowned dyestuffs suppliers:

- Dystar offers Levafix CA dyes for highest light fastness:

- Levafix Amber CA-N(Non –photochromic)

- Levafix Fast Red CA

- Levafix Blue CA

- Levafix Navy CA

- Huntsman offers Novacron FN dyes for highest light fastness:

- Novacron Yellow FN2R(Non-photochromic)

- Novacron Red FN2BL

- Novacron Blue FNR

- Novacron Navy FN-BN

- Archroma offers Drimaren HF dyes for highest light fastness:

- Drimaren Yellow HF-CD(Non-photochromic)

- Drimaren Red HF-CD

- Drimaren Blue HF-RL

- Drimaren Navy HF-GN

It has been observed that light fastness for pale to medium depth shade depends essentially on red and blue components.

(728)