E-Flow: E-Flow Technology and Sustainability in the Garments Washing Industry: Nano Bubble Technology

Denim jeans are one of the most widely used garments in the fashion industry. Due to their durability, versatility, and widespread appeal, jeans are a staple across all demographics. However, the traditional washing and finishing processes of denim require excessive amounts of water, energy, and chemicals, contributing to environmental pollution. With increasing global concerns about sustainability, the textile industry is seeking alternative solutions to minimize its environmental footprint.

One such breakthrough technology is E-Flow, developed by the Spanish company Jeanologia. This Nano Bubble Technology is revolutionizing denim finishing by drastically reducing water consumption and eliminating hazardous chemical discharges.

What is E-Flow Technology?

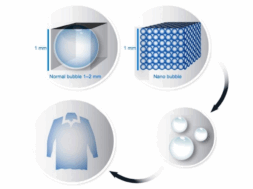

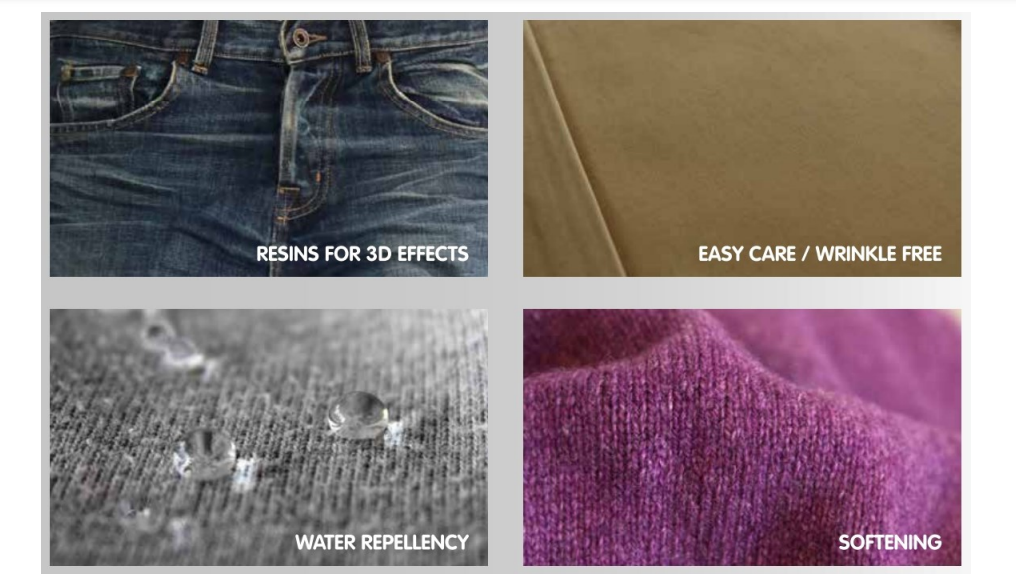

E-Flow is an innovative sustainable garment finishing technology** that utilizes nano bubbles to transfer chemicals onto fabric surfaces with minimal water usage. Unlike conventional wet processing methods that rely on large volumes of water, E-Flow employs air and a small amount of water to achieve desired effects like softness, color fading, and controlled shrinkage in garments. This ensures zero discharge of pollutants into the environment.

Why is E-Flow Technology Important?

The conventional denim washing process involves multiple stages of water-intensive treatments, including de-sizing, bleaching, neutralizing, and softening.

These processes generate high levels of effluent containing harmful chemicals and dyes, leading to:

- Water scarcity in textile manufacturing regions.

- High energy consumption due to heating and drying processes.

- Chemical pollution affects both human health and aquatic ecosystems.

E-Flow technology significantly reduces these environmental hazards, making it a game-changer for sustainable textile production.

How Does E-Flow Technology Work?

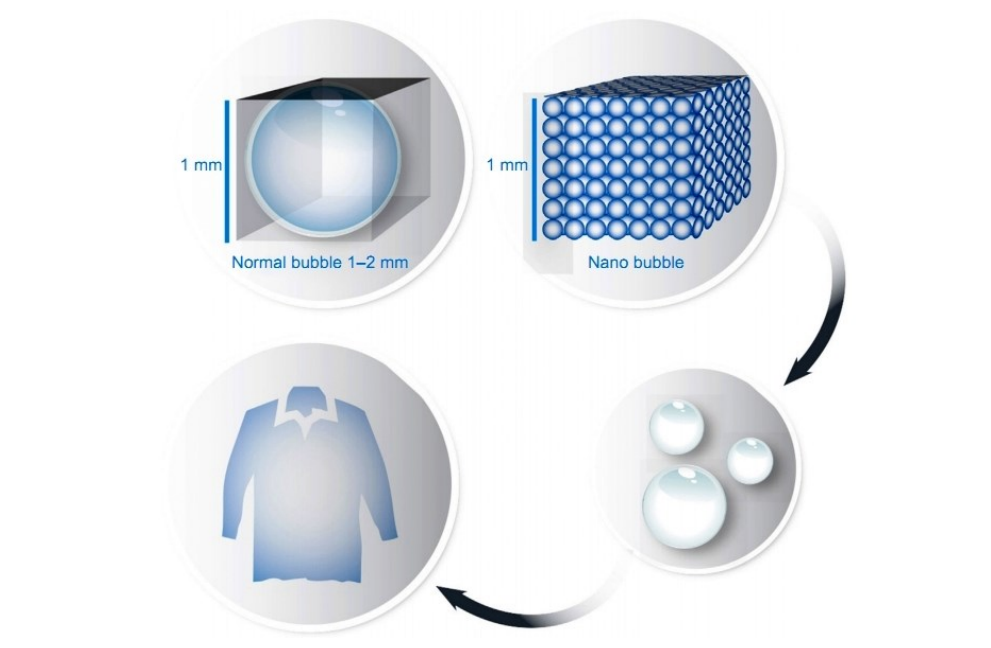

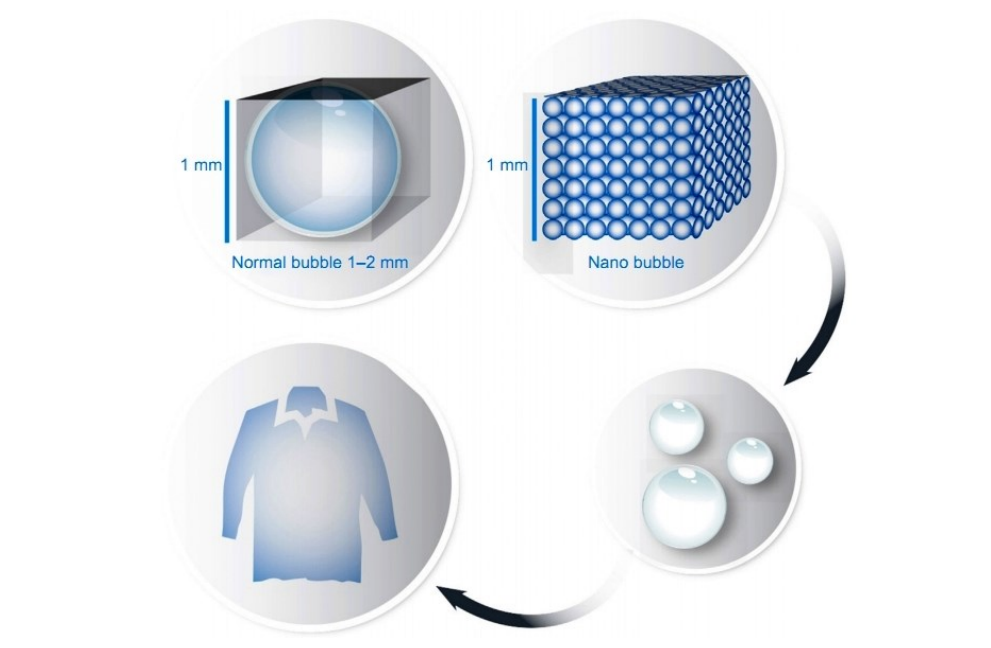

- Nano Bubble Generation: The E-Flow system creates nano bubbles by introducing air from the atmosphere into an electromechanical reactor.

- Chemical Mixing: These nano bubbles mix with a small quantity of chemicals in a specialized chamber.

- Application to Garments: The mixture is transported into a rotating tumbler containing the denim garments, where the nanobubbles distribute the chemicals evenly.

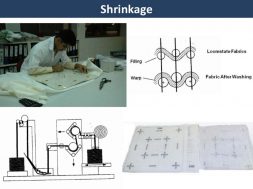

- Drying & Finishing: The treated garments are dried within the same system, ensuring a controlled shrinkage and soft feel.

Benefits of E-Flow Technology

- Water Savings: Reduces water consumption by up to 98% compared to conventional washing.

- Energy Efficiency: Reduces energy consumption by up to 47%, lowering operational costs.

- Chemical Reduction: Eliminates the need for harmful chemicals, resulting in zero discharge.

- Soft Hand Feel & Comfort: Enhances fabric softness and increases rub fastness.

Real-World Application of E-Flow Technology

Many global brands and manufacturers have integrated E-Flow technology into their denim production processes. Some practical examples include:

- Leading denim manufacturers like Levi’s and H&M using E-Flow to achieve sustainable garment finishes.

- Bangladesh’s RMG sector incorporating Jeanologia’s innovations to reduce environmental impact.

Challenges and Future Prospects

While E-Flow technology has proven to be highly effective, its widespread adoption faces a few challenges:

- High Initial Investment: Many manufacturers hesitate to invest in new machinery due to high setup costs.

- Limited Awareness: Some industry professionals are unaware of the long-term benefits of nano bubble technology.

- Lower Load Capacity: Compared to conventional washing machines, E-Flow systems have a lower garment loading capacity, which may require workflow adjustments.

Despite these challenges, the future of E-Flow technology in the textile industry looks promising. As brands and consumers demand eco-friendly fashion, sustainable technologies like E-Flow will become standard practice in denim washing.

(237)