Jute Fibre Properties and End Uses | Part 02

Part 01 : Jute Fibre | Jute Fibre Cultivation

Physical and Chemical Properties of Jute Fibre| Chemical Composition | End Uses of Jute Fibre

Introduction:

Jute is known as golden fibre because of its golden color & it will bring a golden future for Bangladesh. In terms of usage, production and global consumption, jute is second only to cotton. Once upon a time before liberation it was the main exporting goods and was sold in raw & finished goods. Jute is a bast fiber used for sacking, burlap, and twine as a backing material for tufted carpets.

Morphological Structure:

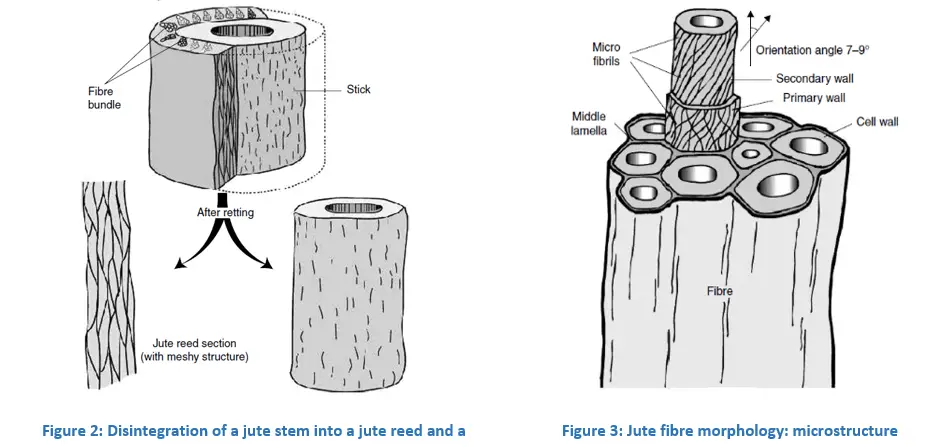

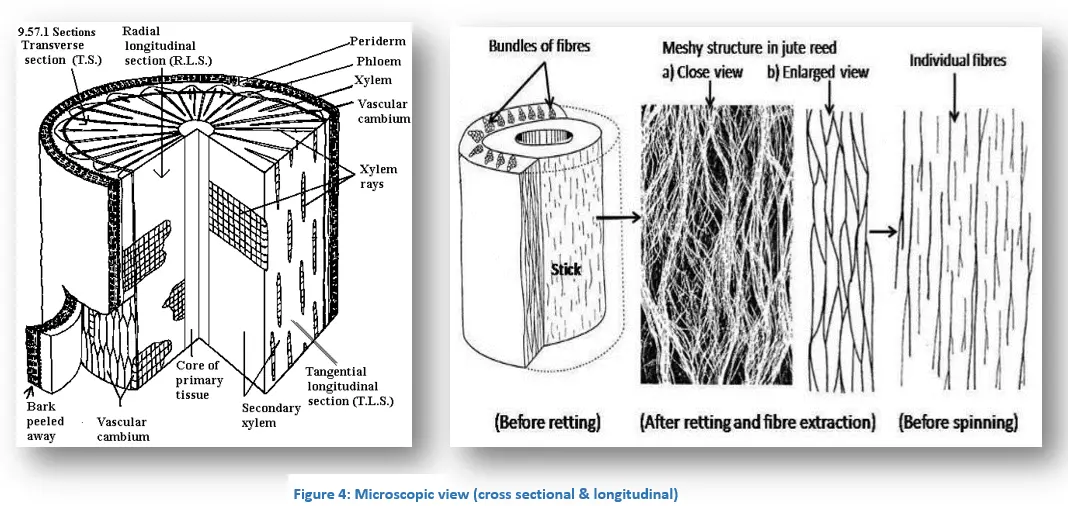

Jute fibre is a multicellular fibre. It is formed as a cylindrical sheath made with single fibres joined together by three dimensional network from top to bottom of the steam.

1 . Macro structure: Each fibre element visible by naked eye, of a raw jute reed available commercially is basically a group of about 5-15 ultimate cells, cemented together laterally and longitudinally by means of inter cellular materials being chiefly non cellulosic in composition. Thus jute fibre is multicellular. For this, jute fibre is much coarser than cotton which is unicellular. The ultimate cells are spindle shaped and of variable size in length and width, being on an average 2.5 mm long and 0.02 mm width at the middle. The cross-section of the ultimate cells are found to be polygonal with rounded corners. The layer of natural cement present between the ultimate cells is known as middle lamella. Each ultimate cell has thick cell wall and lumen, the central canal with more or less oval cross-section.

2 . Micro structure: The cell wall of each ultimate cell is composed of an outer thin primary wall and an inner thick secondary wall, differing from each other in the molecular architecture. Both these walls of jute ultimate cell are compared of ultra-fine micro fibrils. While in the primary wall the fibrils are lying in crisscross manner, the fibrils are almost parallelly arranged as right hand spirals in the secondary wall.

Microscopic View:

Physical Properties:

|

Sl. No. |

Parameters |

Properties |

|

1 |

Ultimate length |

1.5-4 mm |

|

2 |

Ultimate diameter |

.015-.020 mm |

|

3 |

No. of ultimate in X-section |

6-10 |

|

4 |

Fibre length |

5-12 feet |

|

5 |

Color |

White, Off white, Yellow, Brown, Grey, Golden |

|

6 |

Strength |

3-4 gm/den |

|

7 |

Elongation |

1.7% at the break |

|

8 |

Specific Gravity |

1.5 |

|

9 |

Moisture Regain |

13.75% |

|

10 |

Resiliency |

Bad |

|

11 |

Dimensional Stability |

Good |

|

12 |

Abrasion Resistance |

Average |

|

13 |

Effect of Light and Heat |

Average |

|

14 |

Effect of Micro Organism |

Good (better than cotton) |

Chemical Properties:

1 . Effect of Acids: Easily damaged by hot dilute Acids and conc. cold Acid.

2 . Effect of Alkalis: Fibers are damaged by strong alkali. Fibers losses weight when it heated with caustic soda.

3 . Effect of Bleaches: Resistant to bleaching agents (Bleaching agent, H2O2, NaOCl, NaClO2, Na2O2, CH3COOH, KMnO4 etc.)

4 . Effect of Light: Color changes slightly in presence of sun light. It happens due to presence of lignin in fiber.

5 . Effect of Mildew: Prevention ability is better than Cotton and Linen.

6 . Dyeing ability: Easy to dyeing. Basic dye is used to color jute fiber.

Chemical Composition :

| Sl. no. | Chemical | Composition % |

| 1 | Cellulose | 65.2% |

| 2 | Hemicellulose | 22.2% |

| 3 | Lignin | 10.8% |

| 4 | Water soluble | 1.5% |

| 5 | Fat & wax | 0.3% |

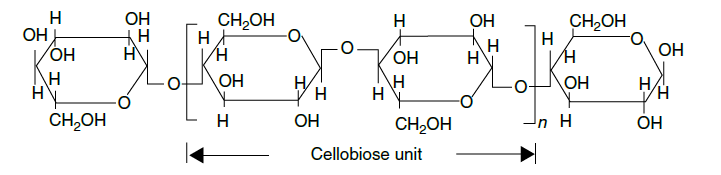

Chemical Structure of Cellulose:

Figure 5: Chemical structure of alphacellulose

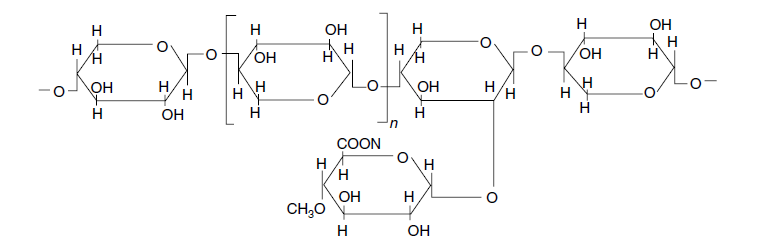

Figure 6: Chemical structure of hemicellulose

Identification of jute fiber:

There are different tests which could be used for the identification of the jute fiber.

There are given below :

Non-technical Test:

- Feeling test

- Burning test

Technical Test:

- Microscope test

- Density measurement test

- Staining test

- Chemical test

Feeling test: Stiff and a harsh hand to human skin, feels bad against skin.

Burning test: Not melt, burn easily, smell like paper burning, because paper is also a cellulosic material.

Microscopic identification: Polygonal shaped cross-section and many ultimate cell of longitudinal view identified jute fiber.

Solubility: Jute is dissolved in 58% H2SO4 in warm condition.

Staining: To study the morphology of fiber surface.

Uses & applications :

Jute fibre is used for various types of jute goods. The finer quality of jute are made into curtains and furnishing fabrics. Jute can be mixed with wool for fine yarn and fabric production.

Familiar uses:

- Packaging: bags, sacks, wrapping material i.e. cotton packs and wool packs.

- Geotextiles – landfill covering, embankment reinforcement.

- Braids and webbing

- Cable filler

- Rope

- Furniture

- Camp beds

- Filter cloths

- Hand bags

- Covering fabrics

Part 01 : Jute Fibre | Jute Fibre Cultivation

(4313)