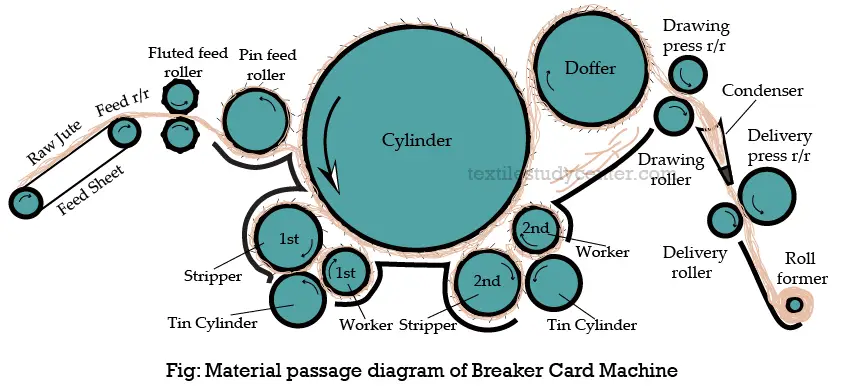

Breaker Carding Machine

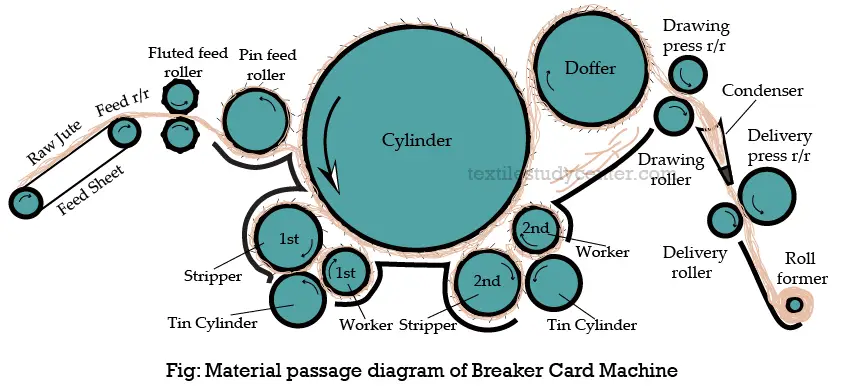

Name of the Experiment: Study on material passage diagram of Breaker Carding Machine

Introduction:

After the fiber from the softening machine has been conditioned for the desired time, it is ready for one of the most important processes in the cycle of jute manufacture: this process is termed carding. In the carding, the operation the long strands of jute are converted into a continuous ribbon of fibers. The ribbon is known as sliver. Different qualities of jute in the batch are also blended and much shorter fibers are removed too. The machines used in the carding process are generally two types-

- The breaker card

- The finisher card

Breaker Carding:- In different jute mills the carding operations has been carried out in two ways:

- Hand feed breaker carding.

- Roll feed breaker carding.

The material after piling more than 24 hours is used hand feed breaker where the material after piling for 12 hours used in the roll feed carding. In this machine, softened jute, after pilling, is fed by hand in suitable mass. By action with different rollers, the machine turns out raw jute in the form of jute slivers for finisher carding. Breaker cards are usually half circular and down striking and have two pairs of workers and strippers. In this process, root cutting is necessary before feeding the material to the hand-feed breaker carding machine.

Objectives:

To Split up & Breakdown the jute fiber.

To individualize & parallelize the jute fibers.

To straighten the jute fibers.

To remove trash from jute fibers.

To remove short fibers.

To convert the reeds of jute into a uniform fibrous strand, sliver suitable for further processing.

Input: Emulsified long reeds of jute

Output: Breaker carded sliver

Main Parts:

- Motor

- Motor shaft

- Feed roller

- Pin feed roller

- Shell

- A big Cylinder

- A pair of worker

- A pair of Stripper

- A pair of tiny cylinder

- Doffer

- Drawing roller

- Drawing press roller

- Condenser

- Delivery roller

- Delivery press roller

- Roll former

Working Principle:

Normally 6-8 roll spreader slivers are feed onto the feed sheet from a creel at floor level and material passes up towards the feed rollers of the breaker card.

① The jute now enters the space between the shell and pin feed roller which travels towards the swift moving pins of the main cylinder.

② When the feeding ends of the reeds meet these fast-moving pins, then they are split, opened out and converted into a fibrous beard.

③ After shell feed operation, the jute reeds come into the real carding action carried out by two pairs of workers and strippers.

④The essential features of this worker and stripper action are combing, teasing, spitting as the fiber is transferred from the cylinder to worker, then from the worker to stripper and finally from the stripper back to the cylinder.

⑤ The wastage is then discharged through the tin cylinder.

⑥ In this way, jute fiber passes 1st and 2nd worker stripper pairs.

⑦ After leaving the 2nd worker stripper pair, the thin sheet of combed and split fibers comes into contract with the pins of the doffer from which it is removed by the drawing and pressing rollers.

⑧ Then the sheet of fibers emerges from these rollers into the broad and upper part of the condenser.

⑨ The thin sheet of fibers are delivered to delivery roller and delivery processing roller.

⑩ Finally, the sliver is obtained in the roll form with the help of roll former.

Conclusion:

Breaker card is one of the most important machine in jute manufacturing technology. By this experiment, we know about material passage diagram of this machine. These will surely help us in our future life.

(5998)