Clothing Made From Pinapple Fibre Called Pina

Clothing Made From Pinapple Fibre Called Pina

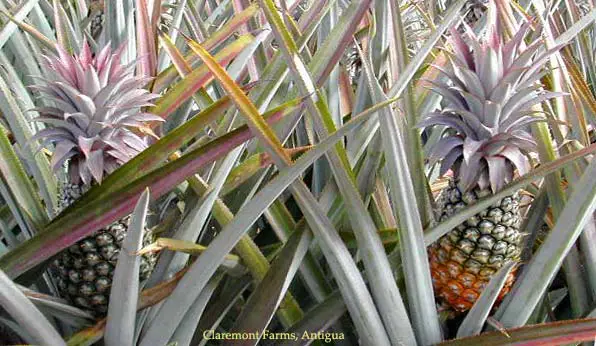

Pineapple is a fruit which is known to all. We think that only fruit is useful and other parts of the fruit are garbage. What we think is wrong. We can produce fiber from pineapple leaf which is known as pina fiber and is natural fiber also. Fibers which are obtained from stem, bark or leaf of certain vegetables plants are called bast fiber. So, pina is also a bast fiber. This fiber is commonly used in Philippines. Sometimes this fiber is combined with silk and polyester to create textile fiber for more luxture, strength or fineness. This fiber is biodegradable so that the expectation of greening the today’s world is come into use.

Physical properties of Pina:

|

Parameters |

Properties |

|

Length |

3-9mm |

|

Breadth |

4-8 mm |

|

L/B ratio |

450 |

|

Gravimetric Fineness |

1.54(tex) |

|

Tenacity |

50(gm/tex) |

|

Extension of break |

2-6% |

|

Flexural rigidity |

3.8 (dyne cm-2) |

|

Density |

1.48(gm/cc) |

|

Moisture regain |

65% |

|

Color |

Ivory-white color |

Chemical properties:

The chemical composition of jute is given below:

|

Compositon |

percentage |

|

Holocellulose |

87.56% |

|

Alpha-cellulose |

78.11% |

|

Hemicellulose |

9.48% |

|

Lignin |

4.78% |

|

Pectin |

2-3% |

Effect of bleaching : Not affected by oxidizing and reducing agent.

Effect of alkali : Easily damage by hot dilute or cold concentration acid.

Effect of organic solvent : Resistance of organic solvent.

Effect of sunlight : Poor sunlight resistance, scorches at high temperature.

Crystallinity : 150

Extensibility : 2.5 times extensible than jute.

The degree of polymerization : less by 40% than cotton.

Pina loss his strength when its buried under the ground.

Products from pina:-

- Paper

- Reinforced Plastic

- Reinforced Roofing

- Decorative Purpose

- Upholstery: Tommy Bahama pineapple paradise ablong toss pillow.

Advantages:

There are different ways to recycle the pina wastes and substitutes for cotton and any other fiber:-

- To produce silky white fiber from pineapple waste using biotechnology.

- To compare the biotechnologically produced fibers with the commercially natural fibers for its qualities.

- To curtail the disposal problems of pineapple processing industrial waste.

- To minimize the use of forest resources by using non woody resources like organic waste.

- Biotechnological engineering of waste to fiber.

- Employment opportunity for rural people.

- Cloth is wear-resistance.

- It is easy clean and dry but dry cleaned is not needed.

Disadvantages:

- Very expansive.

- Production method is carefully to do.

Cultivation of pina:

First , pina is produce from a leaf , so the leaf has to be cut from tree.

Second , the fiber has to be pulled or split away from the leaf.

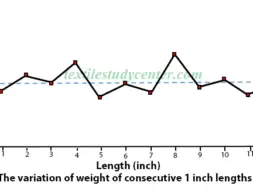

Third , Most leaf fibers are long and some what stiff.Each strand of is hand scraped and it is knotted one by one to form a continuous filament to be handwoven.

Fourth , Pina is intensive, as each is done mostly by hand.

Producers:-

Kalibo, Aklan, is the main and the oldest manufacturer/weaver of piña cloth in the Philippines which are being exported to various parts of the world most particularly North America, and Europe. Pina weaving is an age-old tradition which was recently revived in the past 20 years. During the 1996 APEC summit held in the Philippines, world leaders donned Barong Tagalog made of piña sourced from Kalibo during the group photo.Producers include La Herminia Piña Weaving Industry, Malabon Pina Producers and Weavers Association, Reycon’s Pina Cloth and Industry, and Rurungan sa Tubod Foundation.

(1414)