Flammablity Test

Flammablity Test

Flammability

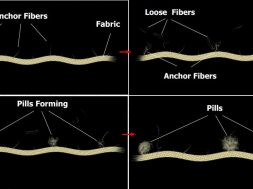

It is the ability to burn or ignite any substance by means of fire or any kind of combustion. Various test procedures exist to determine the flammability. In domestic sphere many serious and tragic accidents are the results of clothing catching fire.Flameproof fabrics are absolutely necessary for protective clothing in many industrial processes where chances of inflammable fabrics being ignited are high.

Some terms and definitions related to flammability

Flammable : A flammable fabric is one which propagates flame, i.e. it continues to burn after the igniting flame has been removed.

Flameproof : A flame proof fabric is one which doesn’t propagate flame, i.e. any flame goes out quickly when the igniting flame is with-drawn.

Flame resistance rating : The time(in seconds) necessary for the propagation of flame in a vertical strip( 10o inch).

Flame resistant : A flame resistant fabric is one whose flame resistance rating is high, i.e. above 150.

Inherently flame proof material : A material that has not been subjected to any flameproof processing’s yet it has flame-proof quality.

Durably flame-proof material : The ability of a flameproof material to retain as flame-proof even after being submitted to washing treatment.

Temporarily flameproof material : Material which complies with the requirements of Clause 3 of B.S. 3120, before, but not after, the prescribed washing treatment.

Factors affecting flame resistance

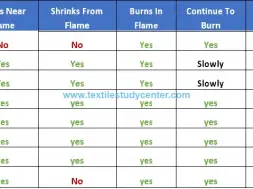

1 . Fibre content : The flame resistance of a fabric is partly dependent on the fibre from which it is made. Cellulosic fibre’s like as cotton, flax, viscos rayon give fabrics of low flame resistance. Wool fabrics are difficult to ignite. Nylons and Terylene(polyester), both are thermoplastic fibre’s, shrink from the flame and tend no to ignite. Although some stiffening treatments and certain dyes can may result in the ignition of nylon and terylene.

2 . Yarn types : Yarn structure does not affect the flame resistance of a fabric.

3 . Fabric structure : Flammability is largely independent of fabric structure. It doesn’t matter whether it is weaved, knitted, laced, bonded, or felted fabric.

4 . Fabric weight : Fabric weight influences flammability of the fabric. For a given fibre the flame resistance rating of fabric has been found to be directly proportional to its weight in ounces(Oz) per Yd2.

Test Methods

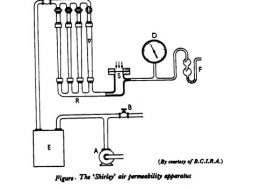

1 . The visual timing test : A fabric strip is suspended vertically and then ignited from the bottom edge, then the rate of flame spread is determined .

2 . The 45 test : In which the time (t), for the flame to travel 5 inch over fabric sloping at 45 degree angle is measured in seconds. The flame resistance rating , M, is then given by (2.5 x t).

3 . The hoop test : In which the rate of flame spread is determined over the fabric mounted on a semicircular frame.

Data for mixture fabrics

|

Description |

Wt. per unit area ( Oz/yd2) |

Rating |

|

20% wool, 80% cotton |

3.7 |

56 |

|

20% wool, 80% cotton |

4.0 |

48 |

|

40% wool, 60% cotton |

3.5 |

45 |

|

50% wool, 50% viscose |

7.7 |

149 |

|

50% wool, 50% nylon |

8.5 |

Infinity |

|

50% wool, 33% viscose, 17% nylon |

7.7 |

213 |

|

50% wool, 33% nylon, 17% viscose |

8.6 |

Infinity |

Data for fabrics treated with flame resistant processes

|

Description |

OZ/yd2 |

Rating |

|

Cotton, Erifon (Lifeguard) treated |

5.9 |

Infinity |

|

Cotton, Proban treated |

5.1 |

Infinity |

|

Cotton, Antiflamm treated |

5.7 |

Infinity |

|

Viscose, Proban treated |

5.1 |

Infinity |

|

Cotton, Antiflamm treated |

5.5 |

Infinity |

Recent Progress in flammability test

Recent tests are modification of vertical strip and 45 degree test , was given by British Standard .Three test methods are given:

Method A :

Basically, this method is the vertical strip test in which the rate of propagation of the flame is measured in terms of the distance in milometers per minute that the base of flame travels up a strip ( 900 mm x 75mm). The time to travel two markers 500 mm apart is observed . The rate of propagation is then given by (500/t x 60 mm/min), where t is in seconds.

some other information’s like after-flame, after-glow, char length are also derived and reported:

1 . After-flame : The time in seconds that elapses between the removal of the std. gas lighting flame and the flame extinction.

2 . After-glow : the time in seconds between flame extinction and the end of any glowing.

3 . The charring : the extent of charring is given by ‘char length. This is the difference in mm between the original specimen length and the undamaged length of the specimen.

Method B :

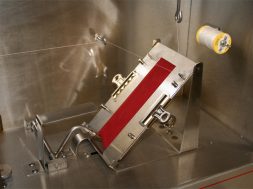

Fabrics made from thermoplastic fibre’s don’t burn in a convenient manner. They melt, shrink, curl away from the flame. In method B the test specimen is hung in the sheet form and the igniting flame applied at right angles to the sheet and near to the bottom edge. The amount of damage and time taken is observed and reported.

Method C :

This test is concerned with the transmission of flame across pile fabrics.

* The lower speed of propagation of flame over wool, silk, acetate fabrics is due to the fact that they melt and drip during burning.

Flame proofing and Flame resistant finishing

Special chemical finishing processes have been developed which reduce the flammability of the treated fabrics. Some recent developments have led to the introduction of such finishes as Proban, Antiflamm, and Lifeguard. Such finishes should have following properties:

- Be permanent and not disappear at the first laundering or cleaning.

- Be non-toxic .

- Be non-irritant to the skin

- Leave the handle and the other desirable properties unaffected.

(2997)