Colour Fastness of Textiles | Color Fastness To Washing

Colour Fastness of Textiles | Color Fastness To Washing

Colour Fastness

The resistance of colour of textiles to fade or bleed against different agencies such as light, wash,water, perspiration, rubbing, acid, alkali,hot pressing, bleaching etc. is called colour fastness.

Colour fastness is a term used in the dyeing of textile materials, meaning resistance of the material’s colour to fading or running. The term is usually used in the context of clothes. The first known use of the word colorfast was in 1916.

Color Fastness To Washing

There are five (5) test methods of I.S.O.-

| Method i,ii,iii | Same procedure but only temperature varies. |

| Method iv,v | Same procedure but only time difference and used for severe purposes. |

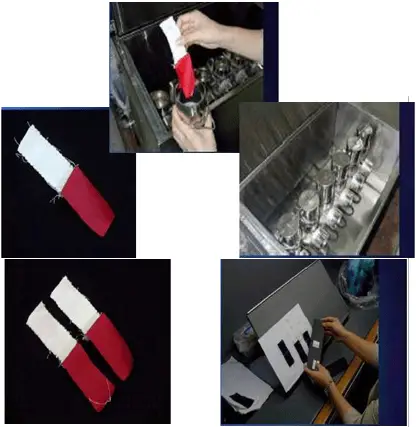

Required Apparatus Color Fastness To Washing :

- SDC recommended multi-fibre fabric or recommended by ISO

- Grey scale for color changing

- Grey scale for staining

- Thermometer

- Dryer

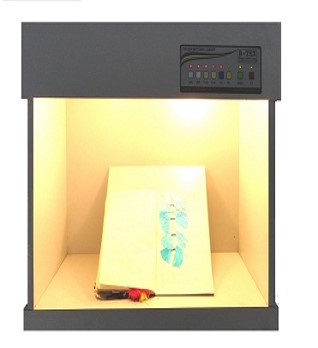

- Color matching cabinet(Light box)

- Sewing machine.

Wash fastness tester and color matching cabinet :

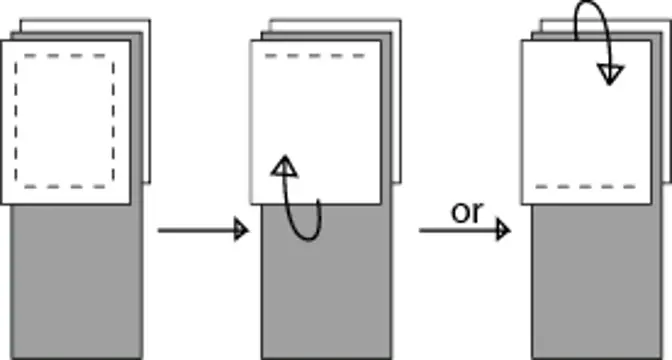

Specimen Preparation of Color Fastness To Washing :

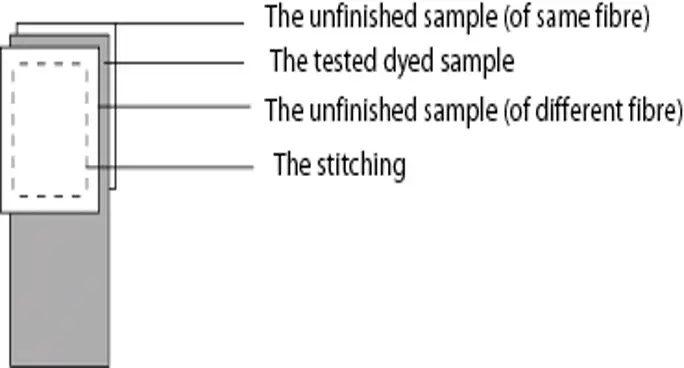

The tested sample is prepared as below:

- A 10 × 4 cm2 dyed sample fabric to be tested is taken.

- Another two pieces of fabric sample of 5 × 4 cm2 which are scoured, bleached but undyed is also taken-

- One will be same fabric undyed

- Other will be a multifibre fabric or indicated by ISO

- Now the dyed sample is placed between the undyed samples covering 5 × 4 cm2 area and stitched at the four edges, leaving 5×4 cm2 exposed, thus the specimen is ready for test

For Test Method i, ii and iii :

|

If the first piece is |

The other piece will be |

|

Cotton |

Wool |

|

Wool |

Cotton |

|

Silk |

Wool |

|

Polyester |

Wool or cotton |

|

Acrylic |

Wool or cotton |

|

Nylon |

Wool or Cotton |

For Test Method iv and v :

|

If the first piece is |

The other piece will be |

|

Cotton |

Viscose |

|

Viscose |

Cotton |

|

Nylon |

Viscose or cotton |

|

Polyester |

Viscose or cotton |

|

Acrylic |

Viscose or cotton |

Washing solution of Color Fastness To Washing :

| Methods | Solution |

| For ISO i, ii, iii method |

5 gm/litre any of following two-

|

|

For ISO iv and v method |

ISO reference detergent – 5 gm/litre Anhydrous sodium carbonate – 2 gm/litre |

The reagents and material are taken in a wash wheel and the recipes are as bellow –

|

Test method |

Temp(0C) |

Time |

M:L Ratio |

|

ISO-1 |

40º ± 2ºC |

30 min |

1:50 |

|

ISO-2 |

50º ± 2ºC |

45min |

1:50 |

|

ISO-3 |

60º ± 2ºC |

30min |

1:50 |

|

ISO-4 |

95º ± 2ºC |

30min |

1:50 |

|

ISO-5 |

95º ± 2ºC |

4hours |

1:50 |

After-treatment of Washing :

- After 30 minutes specimen is taken out.

- The specimen is rinsed twice in cold distilled water.

- Then it is washed in running cold water for 10 minutes.

- The specimen is squeezed and the stitching is removed from two long side (5 cm sides) and one short side (4 cm side) leaving another short side .

- It is dried at a temperature <= 60ºC.

- Then the rest side is unsewed.

Assessment :

Change in colour :

The exposed part is compared with original dyed fabric with the help of grey scale. .

Staining :

The undyed fabric used for covering is compared with the original undyed fabric by grey scale for staining.

(805)