Jute Fibre | Jute Fibre Cultivation | Part 01

Part 02 : Jute Fibre Properties and End Uses

Jute Fibre | Jute Fibre Cultivation | Grading System of Jute Fibre | Producing Countries of Jute Fibre | Part 01

Introduction:

Jute is known as golden fibre because of its golden color & it will bring a golden future for Bangladesh. In terms of usage, production and global consumption, jute is second only to cotton. Once upon a time before liberation it was the main exporting goods and was sold in raw & finished goods. Jute is a bast fiber used for sacking, burlap, and twine as a backing material for tufted carpets.

Origin:

In all continents and in numerous tropical and sub-tropical regions, Corchorus species are found in warm regions throughout the world. C . Capsularis is universal in Indo-Myanmar and South China and from where it migrated to India and Bangladesh. The primary centre of origin of C. Olitorius is probably Africa and the secondary region is India or indo-Myanmar.

Requirements for growth:

Jute is essentially a tropical plant and requires high temperature (95-85 0F) and high precipitation. It needs well penetrative soil, suitable seeds, rainfall over 40, a sufficient supply of water retting plants and washing the stripped fibres.

Cultivation :

For good production of jute the soil type needs mainly silt, laterite and calcareous with soil texture varying from sandy loam to clay loam. The soil should be well drained and its PH range should be 5.5-6.5.it needs humid climate with temperature of between 24°C-38°C, the optimum being around 34°C and humidity between 70%-90%, minimum rainfall requires 1000 mm though line sowing or planting in lines has many advantage such as 50% lower seed rates, fewer rounds of thinning and weeding. It has an opportunities to reduce costs by utilizing mechanical implements for sowing, thinning and weeding, more convenient harvesting and generally higher fibre yields. Usually 6–8 t/ha of farmyard manure are applied to the field during land preparation. Raking, thinning and weeding are generally adopted in all jute fields, which are best practised under optimum soil moisture conditions.

Harvest:

Jute is generally harvested by the calculation of crop age, height and flowering stage. It needs 110-120 days are required to mature for harvesating. Jute is generally harvested when the plants are at early pod stage. The fibre remains weak if it is harvested before flowering. On the other hand, the fibre becomes coarse and lacks luster if harvesting is delayed beyond 120 day age.

Retting:

For fibre extraction, the jute stems are retted in water for 3-4 days, after harvesting and defoliation of plants in the fields. The traditional method is to ret the jute stems for about 15–18 days and extract the fibre manually after retting. Retting is used for breaking down the soft tissues around the fibre bundles and the fibres by bacteria. Retting is complete when the bark separates out easily from the core. Before extraction, the farmers make frequent checks to determine the end-point of retting. Correct retting is essential for the production of good quality fibre.

There are also other methods of retting, chemical, enzymatic/microbiological etc. advocated by different scientists/researchers.

Extraction:

After retting, plants are taken out of water and the fibre is traditionally extracted by hand.

Washing:

The washing process consists of holding the extracted fi bre bundle by the butt end and jerking it through the water. Clean water is used for washing. The entire dirt, gum, extraneous plant materials and retting residues are removed thoroughly.

Drying:

The washed fi bre is spread over a bamboo perch or bar for thorough sun drying for 4–7 days before storage. Drying on bare ground is discouraged, because it affects quality of fi bre by contamination with dirt, sand, dust particles, etc.

Up-gradation Process:

Up-gradation of jute fibre at different stages of preparation of the commercial raw material has been continuously attempted through chemi-mechanical, chemical, and biological means by various workers and is still in the process of modifications and refinements. Most of the earlier attempt proved futile, either because of high process cost or extensive labor involvement. Some of the processes of proven ability to improve fibre quality are rather of academic interest. Others, involving manipulations at pre-retting stage, have been experimented in large-scale field trials. Considering the multifaceted limitations, it was considered worthwhile to develop a simple process which could upgrade the quality of fibre. The basic proportion was to identify the combination of chemicals which would significantly contribute to the quality.

- Substrate

- Retting and Fibre Extraction

- Post retting chemical treatment

- Fibre gradation

- Chemical Analyses

- Color measurement

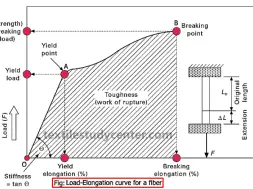

- Measurement of physical properties

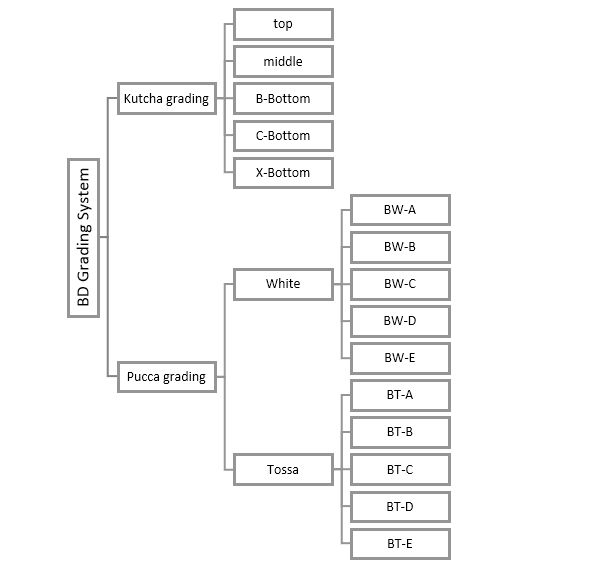

Grading System:

Geographical Distribution:

Almost all the world production of jute comes from india and bangladesh. Most of the jute is grown in the fertile, alluvial, annually flooded area at the mouth of the ganges and brahmaputra rivers, where all the geographical requirements are present. The jute-producing areas of the world are shown in figure.

Producing Countries:

Jute is not cultivated all over the world. It depends on the characteristics of soil. It is specially cultivated in the subcontinent and surrounding countries. Bangladesh and west Bengal of India is the highest jute cultivating area.

|

Sl no. |

COUNTRY |

JUTE PRODUCTION M/T (2017-18) |

% OF WORLD TOTAL |

|

1 |

India |

1,968,000 |

50% |

|

2 |

Bangladesh |

1,452,044 |

42% |

|

3 |

China |

45,500 |

1.3% |

|

4 |

Uzbekistan

|

20,000 |

0.57% |

|

5 |

Nepal |

18,000 |

0.45% |

|

6 |

Myanmar |

17,000 |

0.43% |

|

7 |

Thailand |

12,000 |

0.3% |

|

8 |

Vietnam |

̴12,000 |

̴0.3% |

|

9 |

Sudan |

3,350 |

0.085% |

|

10 |

Egypt |

2,508 |

0.063% |

Part 02 : Jute Fibre Properties and End Uses

(1178)