Zein Fibre | Physical and Chemical Properties of Zein Fibre | Production of Zein fibre

Zein Fibre

Regenerated protein fibers made from corn and maize. Zein fibers were commercially sold as Vicara from 1948 to 1957. They were made with the crushed meal of corn and maize after the oil was extracted. The meal is dissolved in an alkali bath then forced through spinnerets to form fine fibrils that were hardened with Formaldehyde. Fabric made from zein fiber is soft, tough and strong and has the warmth of wool. It is resistant to mildew, insects, sunlight, and temperatures to 140 C. Vicara was usually blended with Cotton, Wool, or rayon. It was used in suits, sweaters, blankets and pile fabrics.

Physical and Chemical Properties of Zein Fibre

- Soluble in hot alkaline solutions

- Insoluble in water, dilute acids and most organic solvents

- Fibers are smooth with a circular cross section

- Tenacity = 1.2 g/denier (dry); 0.65 (wet)

- Elongation 25-35%; (wet); 30-45% (dry)

- Moisture regain = 10%

- Melting Point = 185 (dec)

- Density = 1.25

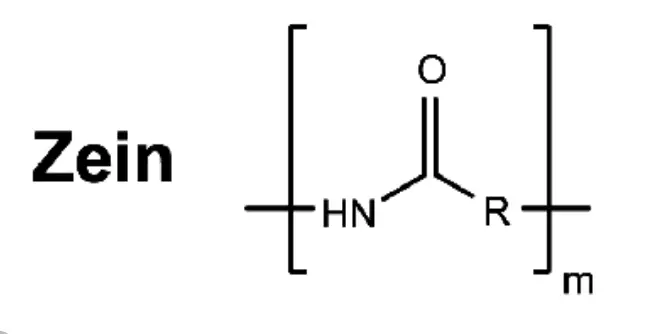

Chemical Structure of Zein Fibre

Production of Zein fibre

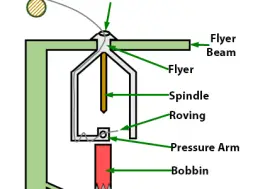

- Zein fibers were successfully prepared by a wet-spinning technique from a zein suspension formulated with 15% zein, 60% water, 22% 0.4N sodium hydroxide, and 3% urea by weight.

- Tenacities were with an Instron machine, and flexibility was determined by noting the smallest diameter rod around which a fiber could be looped without breaking.

- After spinning, the tenacity of the zein fibers was improved by modification with several agents: acetic anhydride for acetylation, glutaraldehyde, and dialcohols for cross-linking and physical stretching.

- The tenacity and flexibility of the fibers were measured at 11.65, and 100% rh.

- Untreated fibers had tenacities of 3.41, 2.65, and 0.17 g/tex at 11, 65, and 100% rh, respectively.

- A combination of chemical treatments (20% glutaraldehyde and 95% acetic anhydride) and 115% stretching increased tenacities to 6.89, 6.56, and 1.17 g/tex at 11, 65, and 100% rh, respectively.

- Control zein fibers had flexibilities of 5 and 2.5 mm at 11 and 65% rh, respectively, whereas the treated fibers had flexibilities of 1.5 mm at both humidities.

- Extrusion of zein fibers was not successful. Zein-soy protein mixture could be extruded, but properties of wet-spun fibers of zein-soy blends were not much improved over those of soy protein alone.

- The tenacity of blended soy protein-zein fibers was greater than that of soy protein fibers at 11% rh.

Applications and Uses of Zein Fiber

- In textiles, Fabric made from zein fiber is soft, tough and strong and has the warmth of wool.

- It is resistant to mildew, insects, sunlight, and temperatures to 140 C.

- Vicara was usually blended with Cotton, Wool, or rayon. It was used in suits, sweaters, blankets and pile fabrics.

- Historically, zein has been used in the manufacture of a wide variety of commercial products, including coatings for paper cups, soda bottle cap linings, clothing fabric, buttons, adhesives, coatings and binders.

- The dominant historical use of zein was in the textile fibers market where it was produced under the name “Vicara”. With the development of synthetic alternatives, the use of zein in this market eventually disappeared.

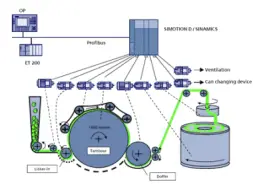

- By using electro spinning, zein fibers have again been produced in the lab, where additional research will be performed to re-enter the fiber market.

- It can be used as a water and grease coating for paperboards and allows recyclability.

Areas of Trades :

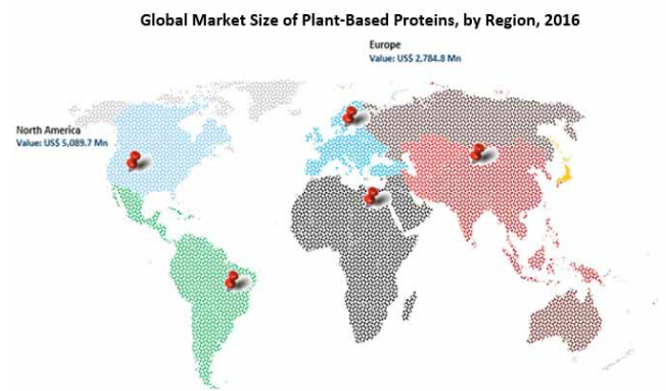

The Zein Protein market can be segmented on the basis of source, end-use, and distribution channel.

Some of the key players in the Zein Protein market includes:

- Zein Products

- Archer-Daniels Midland Company

- Glanbia plc.

- AGT Food & Ingredients

- Burcon Nutrascience Corporation

- Penta International

- I. DU PONT DE NEMOURS AND COMPANY

- ROQUETTE FRERES

- Cargill Inc.

References:

- https://www.researchgate.net/figure/Chemical-composition-of-groundnut-shells_tbl1_204585292

- https://www.sciencedirect.com/topics/materials-science/zein

- https://www.researchgate.net/figure/Molecular-structures-of-Zein-and-CA_fig1_265966432

- https://www.textiletoday.com.bd/groundnut-protein-fiber-properties-end-use/

- https://textilevaluechain.in/2017/06/15/clothing-from-ground-nut-fibres-2/

- http://cameo.mfa.org/wiki/Zein_fiber

(379)