Twisting and Amounts of Twist for Different Materials – why is the amount of twist in a yarn important

Twisting section/Twisting and Amounts of Twist for Different Materials – why is the amount of twist in a yarn important :

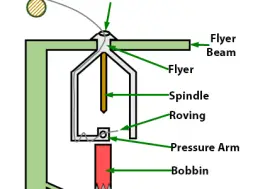

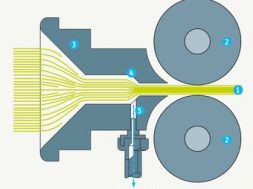

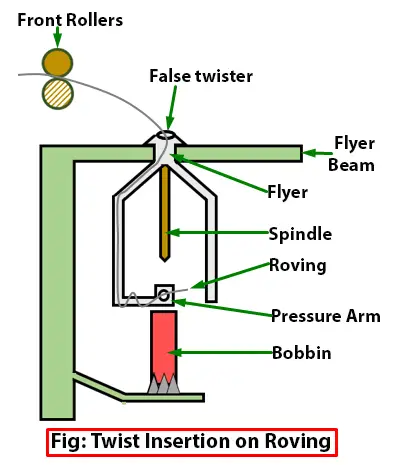

The roving coming out of the front delivery roller is threaded through the top of the flyer, passes through its hollow leg around the presser arm on to the bobbin. The purpose of providing twist in roving is to give the strand sufficient strength to withstand the strain during unwinding in the creel of the ring frame. The insertion of twist is achieved by the rotation of the flyer. Twist level depends on flyer speed and delivery speed of the speed frame. The increase in twist reduces the productive capacity of the machine, so it is generally used in a range as limited as possible. The relationship between the twist and the aforementioned factors is given as follows:

Since the rotary speed of the flyer is constant so the amount of twist inserted per unit length depends upon the delivery rate of the front delivery rollers.

False twisting devices are used on the flyers to add false twist when the roving is twisted between the front roller and the flyer. Because of this supplementary twist, the roving is strongly twisted, and this reduces the breakage rate. False twisting device is also called “twist crown.”

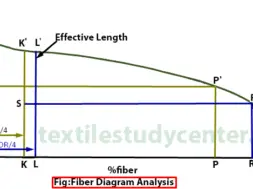

The level of twist imparted in the speed frame process varies with the staple of the cotton and the hank of the roving. Longer cotton requires less twist because individual fibers extend further in the strand and thus help to bind them together more securely than do short fibers. Finer roving requires more twist compared with coarser roving. The level of twist inserted for cotton at the roving frame is about 0.7 to 2 TPI. Higher twist in speed frame reduces the production rate and thus increases the cost of production. On the other hand very low twist makes the roving weak and it can break during the package winding.

Principle of Winding

❶ Bobbin leading principle (For cotton spinning)

❷ Flyer leading principle (For jute spinning)

Bobbin leading principle (NB > NF)

In Bobbin leading the bobbin winds it round itself and the bobbin speed is always more than the flyer speed. But the speed of bobbin decreases as it gets larger in diameter.

Flyer leading principle (NF > NB)

In flyer leading the flyer wraps the roving upon the bobbin in this the speed of flyer is constant but always more than the bobbin. The bobbin starting at certain speed when empty, must gradually increase its rate of revolution as it gets larger in diameter.

(4064)