What Is Loom | Classification Of Loom

What Is Loom | Classification Of Loom :

Loom:

The weaving m/c is technically termed as loom .The loom is a device or m/c in which interlacement of warp and weft yarn performed and thus fabric is produced.

Chronological/historical development of loom

❶ Egyptians made woven fabrics some 6000 years ago.

❷ Chinese made fine fabrics from silk over 4000 years ago.

❸ In the 3rd century, a shedding mechanism was originally invented in China and introduced in Europe.

❹ In 12th century, completely wooden hand looms were used as standard designs in England.

❺ The developments in the design and performance of looms have taken place during the past 850 years.

❻ The fly shuttle, invented in 1733 by John Kay, was hand operated.

It was an important cornerstone to improve the productivity.

This shuttle, running on four wheels, was moving over the lower

side of the warp sheet.

Two wooden tenders connected to a small cord commanded by the hand were used to propel the shuttle. The weaver sitting in the middle of the loom threw the shuttle by pulling the cord very easily.

❼ E.Cartwright invented the power loom in 1785.

❽ In the early 1800s, looms made of cast iron were operated by steam power.

❾ In the 1830s, there were some 100,000 shuttle looms operating in England.

❿ In 1895, many looms, all driven by an electric engine were invented and then became spread.

⓫ At the beginning of 1930’s, eventually, each weaving machine driven individually by an electric motor was developed, this loom drive concept has remained in use until the present.

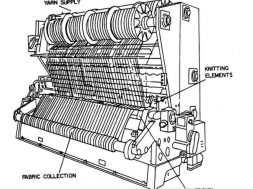

Classification of Loom

or

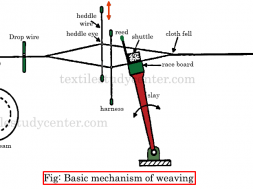

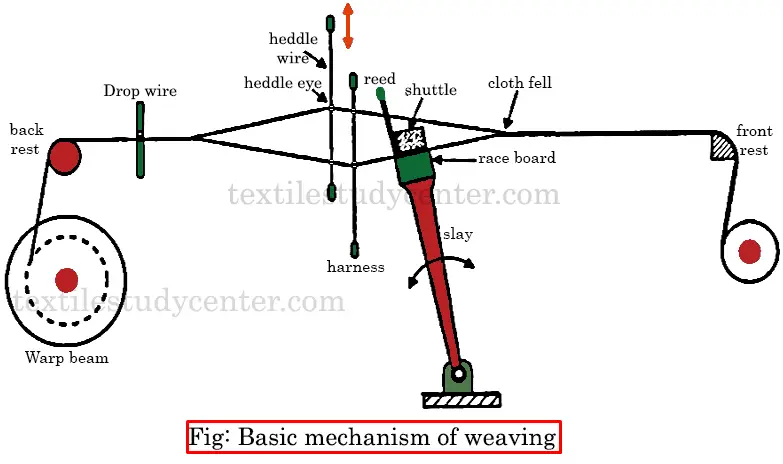

Basic mechanism of weaving

❶ The warp unwound from the warp beam passes round the back rest and comes to the held frames (harnesses),which are responsible for separating the warp sheet for the purpose of shed formation.

❷ It then passes through the reed which holds the threads at uniform spacing and is also responsible for beating up the last inserted pick.

❸ All the threads unite again in the fabric at the point of cloth fell.

❹ The cloth then passes over the front rest and is wound onto the cloth roller.

❺ A drop wire signals the loom to stop immediately after a warp end breaks off.

❻ In conclusion, the warp from the beam is converted into fabric which is taken-up on a cloth roll.

Woven fabric manufacturing process

Some definitions

Drafting: It is the process of passing the warp yarn into the heald eye of heald frame is called drafting.

Drawing: It is the process of passing the warp into the drop wire is called drawing.

Denting: It is the process of passing warp yarn into reed is called denting.

Knotting/Tying-in: The tail end of the warp from the exhausted warp beam is tied to the beginning of the new warp is called knotting/tying-in.

The condition of knotting-

Be easy to tie

There is no variation of count of yarn.

Warp number of new beam must be equal or less than from the exhausted warp beam.

Gaiting: It is the process of setting drawing, drafting, denting in loom is called gaiting.

(6923)