Fabric Thread Density Testing

Fabric Thread Density Testing

For Woven Fabric:

Picks per inch : The number of weft thread per inch is called picks per inch.

Ends per inch : The number of warp thread per inch is called ends per inch.

For Knitted Fabric:

Courses per cm : Course is a row of loops across the width of the knitted fabric and is measured in courses/centimeter.

Wales per cm : Wale is a column of loops along the length of the knitted fabric and is measured in wales/centimeter.

Various Types of Thread Counting Systems and Their Application :

- Counting glass/Pick glass : Most widely used method. Can be used to count courses/inch and wales/inch.

- Traversing thread counter : Like pick glass but improved instrument where the counting pin is moved by means of a handle. Can be used to count courses/inch and wales/inch.

- Fabric dissection method : Most authentic and reliable method and used to count threads of fabric which are too difficult to measure by other methods.

- Taper grating and line grating : Used in cases where

(a) the test results are required in a very short period of time,

(b) where a large number fabric samples are required to test in a very short period of time.

(c) Where the exact test result is unimportant rather a good approximation is required.

(d) Normally fashion designers use this type of instruments.

Identification of Warp and Weft of a Fabric

- The direction of selvedge is warp direction.

- In most cases EPI/EPCm is more than PPI/PPCm

- Normally count of warp is finer than weft

- Generally warp yarn is more twisted yarn than weft yarns.

- If any yarn contains any size particle then the sized yarn is warp yarn.

- Normally stripe effect (both woven and printed) is done in the warp direction.

- Warp yarns are relatively hairy yarn.

- Warp crimp is expected to be less than weft crimp due to high warp tension on the loom.

More Testing :

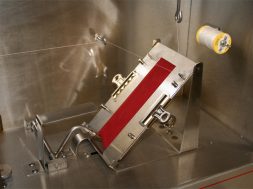

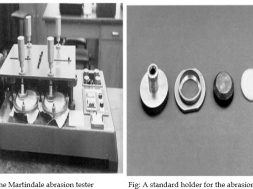

- Fabric Tensile Strength Test | Strip Strength Test | Grab strength test | Tearing strength test | Elmendorf Tear Test | Bursting strength

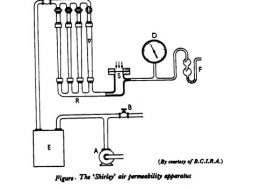

- Air Permeability Test by Shirley Air Permeability Apparatus

(2712)