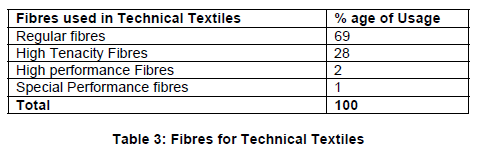

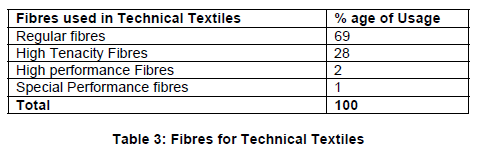

Fibers for Technical Textile

The usages of fibres in the technical textile area are not only the high functional fibres alone, but also the natural (due to bio-degradability and compatibility) and common man-made fibres occupied considerable share, which is shown in table .

( 1 ) Domestic fibres:

Medical Application-Cotton, silk polyester, polyamide are used in medical applications.

Geo Textile-PP and Polyester are used in geo textiles and dry/liquid filtration due to its compatibility.

Biodegradable – Jute and coir (Ligno-Cellulosic) used in biodegradable products and in packaging industry.

Antiballstic and Filtration application– Nylon is been used in the anti- ballistic, Cord, protection and filtration applications.

( 2 ) High functional fibres:

High functional fibres are having high technical properties based on the end uses. The properties are high tensile strength, high modulus, good chemical resistance, high dimensional stability, cut resistance and low thermal shrinkage.

( 2.1 ) Kevlar:

It is Para-Aramide fibre based on terephthalic acid and p-phynelene diamine. It is highly oriented and high crystalline (90%) fibre. It is having good fibre tenacity (about 25gfpd),and high thermal resistance and low thermal shrinkage. This fibre is used for anti ballistic apparel, helmet, industrial protective clothing, gloves, in hot gas filtration, structural composite for air crafts, optical fibre cable sheath, high pressure and automatic hoses, sail cloths and as special tyres cords.

( 2.2 ) Carbon:

It is produced by extruding precursor of acrylics, pitch or specially purified viscose rayon in to filaments, then carbonized to get carbon. After carbonization the fibre processing is a difficult one, hence the precursor fibre may be converted in to fabric, there after it is carbonized to get the required product. Final carbon content could be around 92% by weight. High stiffness to weight ratio (for aero space structure applications), softness, high thermal resistance are the special properties of the carbon fibres.

( 2.3 ) P-phenylene-2.6-benzobisoxazole (PBO):

It is having very high strength (42gfpd) and tensile modulus of 1300-2000gfpd, which is greater then the any known fibre. Good flame resistance and heat resistance (68%-LOI) and high decomposition temperature (600° C). It is used in the anti ballistic vests, protective apparel for fire fighters, lightweight armor for vehicle and for personal.

( 2.4 ) Ultra high molecular weight poly-ethylene (UHMWPE):

It is having high molecular weight (10 6), produced by Gel spinning technique. It is having Low (0.97) specific gravity, high Chemical & abrasion resistances and high strength comparable to Kevlar. It is used in anti ballistic protection, floatable ropes, and nets.

( 2.5 ) Glass:

t is an inorganic and isotropic fibre. High strength, chemical resistance, electrical, resilience, flame resistances and low elongation at break are the salient features of glass. It has a high specific gravity (2.5-2.7), it is used in industrial applications including fire proof, filtration, insulation and in reinforcement.

( 2.6 ) Alumina silica:

Ceramic fibres reported with a very high temperature resistance, used for furnace insulation and hot air filtration.

( 2.7 ) Melamine:

These fibres having 50% by weight of melamine cross-linked polymer (specific gravity about 1.44).It is having outstanding heat blocking properties with low thermal conductivity and good elongation at break (about 18%).

( 2.8 ) Basalt:

It is produced from the basaltoid rocks. Basalt derived from minerals of Plagiocene and pyroxene. This is used for the production of high temperature resistance and chemical resistance products.

( 2.9 ) Noviloid:

This fibre produced with 65% of cross linked novolac, it posses excellent flame retardant properties andrecommended to use up to 150°C in the presence of air and in absence of air it can be used up to 250°C . This can with stand up to 1000°C in short period exposure to flame.

( 2.10 ) Fiber composites for chemical protection:

Acetate, PET, PVC and ploy carbonate sheets used to get clear vision in face shield and goggles. Rubber, PVA, Teflon composite materials used in gloves as a protection layers. TYVAK (spun bonded Ploy ethylene) used in coats and jackets as barrier to chemicals.

(1493)