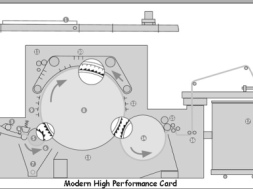

Gearing Calculation of Tappet Loom

Gearing Calculation of Tappet Loom

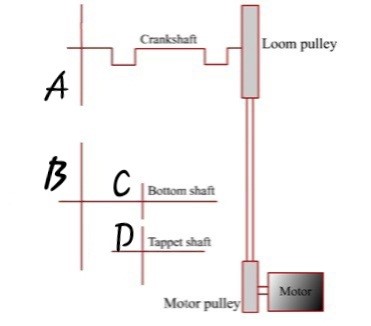

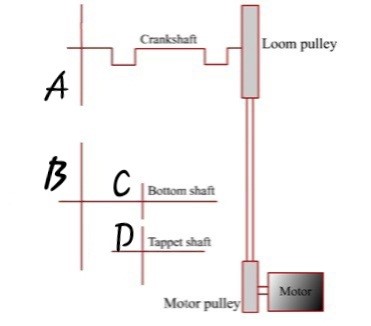

Fig : Gearing Calculation Of Tappet Loom

Here, motor is the main power source. The machine pulley is connected with motor pulley by V belt. So, here motor pulley driver. That means, machine pulley is driven by motor pulley. Crank shaft is connected with machine pulley. The R.P.M. of machine pulley = The R.P.M. of crank shaft. Bottom shaft gets motion by crank shaft via gear A. Here, A is driver. The gear C is connected with gear B by shaft. So, the r.p.m. of B = the r.p.m. of C. Then, the tappet shaft or auxiliary shaft (D) is driven by bottom shaft(C).

In tappet loom, a weaving cycle (that means shedding, picking and beat up) is completed by one revolution of crank shaft, the peaking mechanism is control by bottom shaft. Two peaking cams are situated in the outer side of bottom shaft. The two peaking cams are situated opposite side with an angle of 180°. If bottom shaft rotated 360°, 2 peaks occur. That means 2 weaving cycle will be completed. So, if bottom shaft rotates one time (360°) the crank shaft must be rotate 2 times. That’s why we can say that, the r.p.m. of crank shaft is 2 times greater than the r.p.m. of bottom shaft.

The r.p.m of crank shaft = 2 The r.p.m. of bottom shaft.

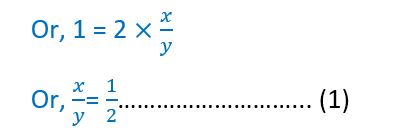

Let, the r.p.m of crank shaft is 1. The teeth number of gear A is x, the teeth number of gear B is y.

So mathematically,

The r.p.m of crank shaft = 2 The r.p.m. of bottom shaft.

That means the ratio of teeth number of crank shafts to bottom shaft is 1/2.

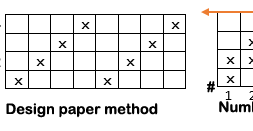

By bottom shaft we can make fabric that repeat size (2 2). If more repeat size is required (that means for more than 2 weaving cycles) auxiliary shaft must be needed.

Finally, we can say that, the use of auxiliary shaft (tappet shaft) depends only the weaving cycle not tappet.

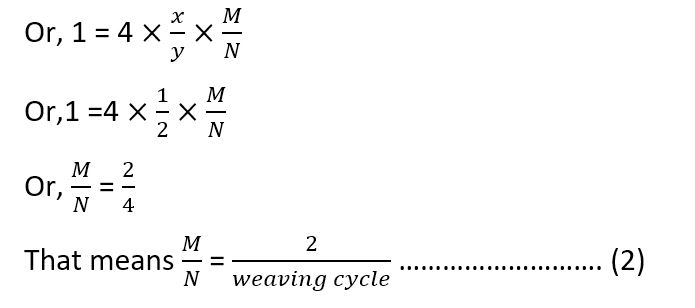

Now we calculated the teeth ratio between Bottom shaft gear C and Auxiliary (Tappet shaft) gear D:

Let, the loom(weaving) cycle is 4; the r.p.m of crank shaft is 1; the teeth number of gear C is M and the teeth number of gear D is N.

So, we can say that, if tappet shaft rotate one times (360°) the crank shaft must be rotate 4 times.

The R.P.M. of crank shaft = 4 The R.P.M. of tappet shaft

So, the teeth ratio of M and N must be 2: weaving cycle (loom cycle)

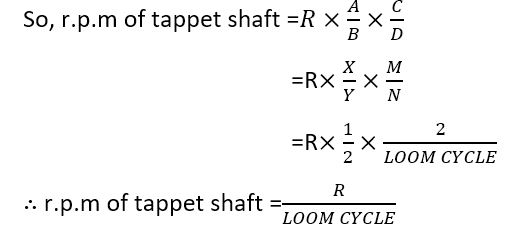

HOW CAN WE CALCULATE THE R.P.M OF TAPPET SHAFT (AUXILIARY SHAFT) FROM THE R.P.M OF CRANK SHAFT.

Let r.p.m. of crank shaft is R

For general formula,

We can write,

THE R.P.M OF CRANK SHAFT = LOOM CYCLE THE R.P.M. OF TAPPET SHAFT.

(740)