Geo-textiles : The Fabric of Erosion Control

Geo-textiles : The Fabric of Erosion Control

One of the most important & Valuable sectors of engineering is Textile Engineering. In worldwide it is hugely elaborated. There are many sectors of Textile Engineering. In our Country Textile Engineering is the main aspects of our National Economy. But the Knowledge of “GEOTEXTILES” is very insufficient in our country.

Geotextile is one of the member of the geosynthetic family. As we know, the prefix of Geotextile, Geo means earth & the “Textile” means fabric. So a permeable geosynthetic comprised solely of textiles. Geotextiles are used with foundation, soil, rock, earth or any other geotechnical engineering related material as an integral part of human made project, structure or system.

Geotextiles were originally intended to be an alternative to granular soil filters. The original, and still sometimes used, term for geotextiles is filter fabrics. Work originally began in the 1950s with R.J. Barrett using geotextiles behind precast concrete seawalls, under precast concrete erosion control blocks, beneath large stone riprap, and in other erosion control situations.

Geotextiles extend the service life of roads, increase their load-carrying capacity, and reduce the incidence of ruts. These benefits are accomplished by separating aggregate structural layers from subgrade soil while allowing the passage of water (see description on Separation). Geotextiles should be considered for use on any section of road requiring an aggregate (rock) layer for surfacing. Geotextiles can reduce the amount of aggregate required, thus reducing the cost of the road, as well as providing the benefits. For temporary road construction in environmentally sensitive areas, a biodegradable woven jute geotextile has been developed. This fabric will totally biodegrade after one to two seasons, eliminating the need to remove a synthetic geotextile from under the roadbed. It is economical for use on roads that will be decommissioned after use.

There are many uses for geotextiles. The geotextile manufacturer can provide help in selecting the correct material for your specific situation. Rather than describe the many potential conditions under which they may be used, the principles governing their use are described in this section. These principles then can be considered in solving your particular drainage problem.

Geotextiles can be woven, knitted or non-woven. Different fabric composition and construction are suitable for different applications. The non-woven geotextile is an arrangement of fibres either oriented or randomly patterned in a sheet, resembling felt. These geotextiles provide planar water flow in addition to stabilization of soil. Typical applications include access roads, aggregate drains, asphalt pavement overlays, and erosion control. Woven geotextile looks like burlap. It is a fabric made of two sets of parallel strands systematically interlaced to form a thin, flat fabric the strands are of two kinds – slit film which are flat, or monofilaments which are round. The way these two sets of yarns are interlaced determines the weave pattern that in turn determines the best application for that woven fabric. Weave patterns come in a virtually unlimited variety that do affect some properties of the fabric. Woven geotextiles are generally preferred for applications where high strength properties are needed, but where filtration requirements are less critical and planar flow is not a consideration. These fabrics reduce localized shear failure in weak subsoil conditions, improving construction over soft subsoil and providing access to remote areas through separation.

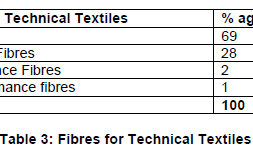

(28)