Man-Made Fibers & Classification of Man-Made Fibers

Man-Made Fibers & Classification of Man-Made Fibers

What Is MMF?

In a very general way, a fiber is defined as any product capable of being woven or otherwise made into a fabric. It may be thought of as the smallest visible unit of textile production. Fibers may be agricultural products (such as cotton or wool) or units (such as nylon or polyester) manufactured in a chemical plant. Fibers than serve as the raw material in the next stage of textile manufacturing.

In seventeenth century a scientist named Hooke suggested that if proper liquid were squirted through a small aperture and allowed to congeal a fiber can be produced. Manufactured (MF) fibers (formerly termed “man-made”) are formed from a suitable raw material as a thick, sticky liquid, which is “spun” or extruded through spinneret holes, forming streams that are solidified into fibers.

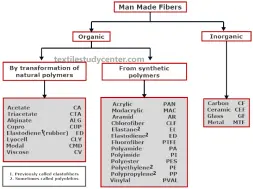

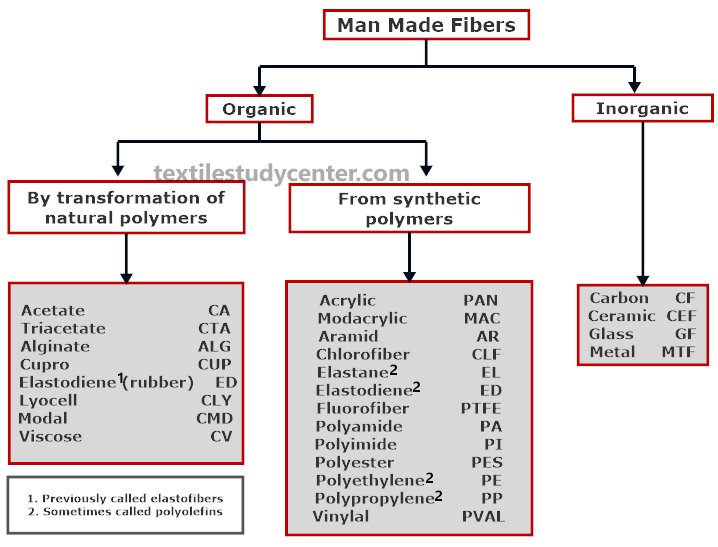

Classification of Man-Made Fibers

OR

Fibers are commonly produced in the following way

❶ Staple fibers

❷ Filaments

❸ Filaments tow

Staple fibers: A staple fiber is a fiber of relatively short length, as is the case with most natural fibers, which range from a few millimeters (e.g. the shortest cotton fibers, known as linters) to around a meter (e.g. fibers from bast plants). Staple fibers are typically between 3 and 20 cm in length. Given the differences in average fiber length, cotton fibers (2–3 cm) and wool fibers (5 cm or more) are, for example, sometimes referred to as ‘short staple’ and ‘long staple’ fibers, respectively.

Filaments: A filament is a fiber of indefinite length. The various silks are the only natural filament fibers. Most regenerated and synthetic fibers are produced as filaments. These can be used in single or multifilament form. Some of these are also assembled to produce a ‘tow’ which is then cut or broken into required short lengths to produce staple fibers suitable for blending with other fibers, in particular with cotton or wool.

Filaments tow: A tow can mean two different things:

In the synthetic fiber industry, a tow is a large assembly of filaments that is destined to be cut into shorter (staple) fibers.

In the processing of natural fibers (flax), tow is the shorter fiber produced when the stalks are processed to extract the fibers (the long fibers are called line flax).

Process Flow Chart of Man Made Fibre Production

Fiber forming polymer/Raw materials

Spinning (conversion to polymer to fiber)

Drawing/Stretching (To increase strength and crystallinity of molecules)

Texturing (To achieve bulk and grater absorbency)

Intermingling (For thrusting out protruding filament ends)

Heat setting (To improve dimensional stability)

Finished filament

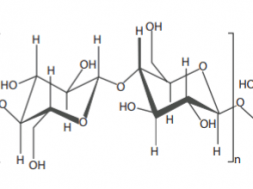

Fiber forming polymer

Fiber forming polymers typically are linear and are capable of being oriented. The molecular weights of fiber forming polymers must be high enough for achieving good mechanical and thermal stability, and at the same time, low enough for dissolving or melting for extruding into fibers. These linear, moderate-molecular weight polymers can be made into fibers by difference type of spinning.

Spinning

Spinning is the process through which bulk polymers are processed into a thread and/or yarn.

All man made fiber spinning process are based on three general steps. These steps are:

❶ Conversion of a polymer into a liquid or spinning solution, also called a dope.

❷ Extruding the solution through a spinneret to from a filament or fiber.

❸ Solidifying the fiber by co-angulation, evaporation or cooling.

Spinneret:

Spinneret is a metal component (made of platinum or iridium) having ten to several hundred small holes. The fluid polymer is injected through these tiny openings to produce filaments from polymer solution. As schematized in figure, a spinneret is similar to a bathroom shower head. The number of holes in the spinneret varies with desired number of filaments required. A small spinneret have up to ten holes, while a large one has more than 10000 holes.

Spinneret features:

Spinneret length: 10-25 mm

Spinneret diameter: 30-200 mm

Spinneret thickness: 3.0 mm

Hole dia: 0.1-0.8 mm

(14477)