Spinning Carding Machine : Chute Feed System

Spinning Carding Machine :Chute Feed System / Flock Feed System :

CHUTE FEED SYSTEM:

The system of feeding small tufts of cotton fibers directly from blow room to the card is called the chute feed system.

Card is arranged in series circuit through pneumatic pipe. Pneumatic tubes are systems that propel cylindrical containers through a network of tubes by compressed air or by partial vacuum. The blow room machinery is linked to the cards by trunking and the opened cleaned cotton is conveyed by pneumatic

means to each card – this is the principle of chute feed system.

ADVANTAGE OF FLOCK/CHUTE FEED SYSTEM:

1. Direct automatic feed to card increases B/R working efficiency.

2. Elimination of man power during scutcher operation.

3. Processing of rejected lap is avoided.

4. Due to loose form of feeding of fibers trash particles can be removed easily

during carding.

5. This is the only solution for higher production

6. Suitable for synthetic fibers bulky in nature.

DISADVANTAGES/LIMITATIONS OF CHUTE FEED SYSTEM:

1. Blow room should run the same number of hours per week as the cards do.

2. The card production must be kept excessive to assure continuous feed to

draw-frame at the time of stoppages at blow room due to maintenance and

other unavoidable problems.

3. Chute feed system control short term variation but not the medium and

long term variations.

4. A reliable check on the nominal count can be established in lap forming

system by controlling total lap weight and C.V. value of the weight per unit

length. There is no such control in the chute feeding system.

5. Change of mixing will result in more waste in chute feed.

6. Auto-leveler is must

7. investment and maintenance cost is higher

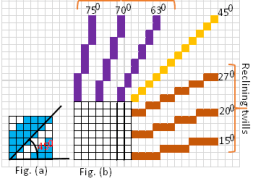

TYPE OF FLOCK/CHUTE FEED SYSTEM:

There are two basic concepts of flock feed:

. one piece chute/single chute:

1. without an opening device

2. simple, economical and requires little maintenance

3. closed system that is excess flock returns to the distributor

4. if too much material is present, neps can be increased

5. not flexible to run different mixings

6. more layout restrictions .

. TWO PIECE CHUTE/DOUBLE CHUTE:

1. with an opening system

2. complex, expensive, but delivers a home uniform batt.

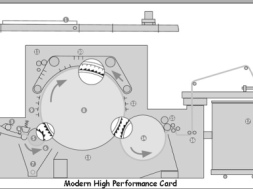

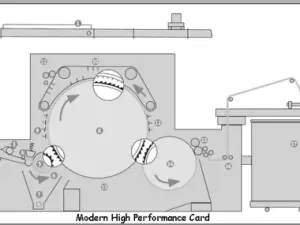

DIFFERENCE BETWEEN CONVENTIONAL AND MODERN CARDING MACHINE:

|

LAP FEED (CONVENTIONAL)

|

FLOCK FEED (MODERN)

|

| 1. whole installation is very flexible. | 2. installation is not flexible |

| 2. auto-leveler is not required. | 2. auto-leveler is a must. |

| 3. lower maintenance and investment cost. |

3. higher maintenance and investment cost. |

| 4. more manpower is needed for transportation of lap. |

4. manpower requirement is less as there is no lap transportation or lap change. |

| 5. linear density of lap is very good (uniform) |

5. linear density of the web fed to the card is not as good as lap. |

| 6. high production is not possible. | 6. flock feed is the only solution for high production. |

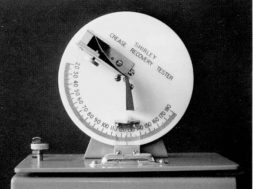

CONVENTIONAL FEED DEVICE:

A WELL DESIGNED FEED DEVICE IS EXPECTED TO PERFORM THE FOLLOWING TASKS:

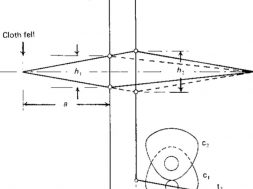

clamp the batt securely over its full width

be able to hold the material back against the action of the licker-in

present the batt to the licker-in in such a manner that opening can be carried

out gently.

conventional feed assembly comprises a stationary feed table with

(1) a feed plate

(2) a feed roller

(3) pressed against the plate.

The feed plate is formed as a special extension of the feed table and is adapted to the curvature of the

cylinder.

(6958)