Surgical Bandages and Surgical Gauzes

Surgical Bandages and Surgical Gauzes

Surgical bandages & surgical gauze are the wound dressings products manufactured from white bleached cotton. The function of surgical gauze is to provide an absorbent material of sufficient tensile strength for surgical dressing. And the function of bandages is to hold dressings in place to provide pressure or support. They may be inelastic, elastic, or become rigid after shaping for immobilization.

Manufacturing Process:

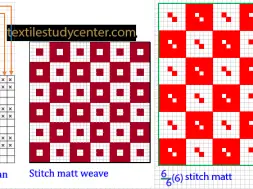

In the process of making surgical gauze/bandage, the raw cotton fiber is mechanically cleaned and then spun or twisted into a thread, and the thread, in turn, woven into an open-mesh cloth with the help of handloom or powerloom. This cloth is gray in appearance and nonabsorbent. It is bleached white and rendered absorbent by much the same processes as those used in the preparation of surgical cotton.

The grey fabric is bleached in boiling kiers and bleaching tubs wherein it becomes white and absorbent. The bandage cloth is also treated with starch. The bleached white fabric is dried by passing in continuous length through a tentering machine. This machine straightens, stretch and hold the gauze taut as it is dried. The bleached white fabric is in the form of rolls of 18-20 meters or as per requirement and transferred to cutting and folding section.

The bandage cloth available is fed into the winding machine for making roll of bandage cloth as the cloth is available in 18 meters length. After sufficient length i.e. about 200 or 300 meters is wound or aluminium square rolls provided for the purpose, this roll will be ready for making small rolls of 3 or 5 meters length or whatever desired length. The bandage roll after winding on the winding machine is put on rolling machine to wind it on stainless steel rod provided under pressure roll to get nicely compressed rolls of different size from 3-4 meter. The paper for covering the roll is passed over the felt roll which rotates by friction of cloth. An adhesive solution is applied at the end of the paper, then the machine again started so that the paper covers entire roll.

The bandage rolls thus prepared can be cut into desired length pieces on the bandage roll cutting machine. Generally the pieces are cut into 3 inch to 6 inch widths. After cutting is over, the cut rolls will drop from the chute fitted on the table. These rolls are charged in autoclave for sterilization for about 5-10 minutes. Thereafter these rolls are collected and packed in dozens or gross for marketing.

A similar process in used for the manufacture of gauze cloth wherein specification of fabric & size of folded gauze is different. The gauze also needs to be sterilized before final packaging.

Process Flowchart :

Cotton Yarn From Spinning

⇓

Weaving of Fabric

⇓

Cotton Grey Fabric

⇓

Bleaching & Washing of Fabric

⇓

Straightening and Drying of Fabric

⇓

Gauze Folding or Bandage Rolling and Cutting ⇓

⇓Blank WritingSterilization

Packaging and Labeling Blank Writing⇑

(351)