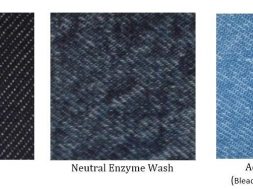

Acid Wash / Random Wash

Acid Wash / Random Wash :

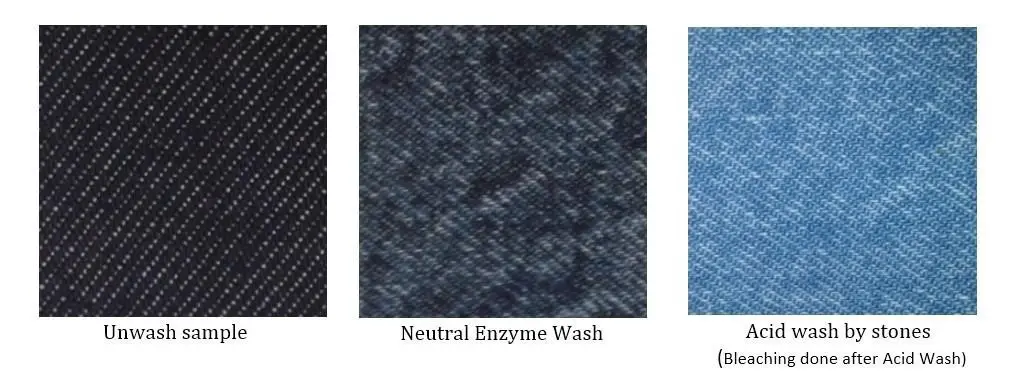

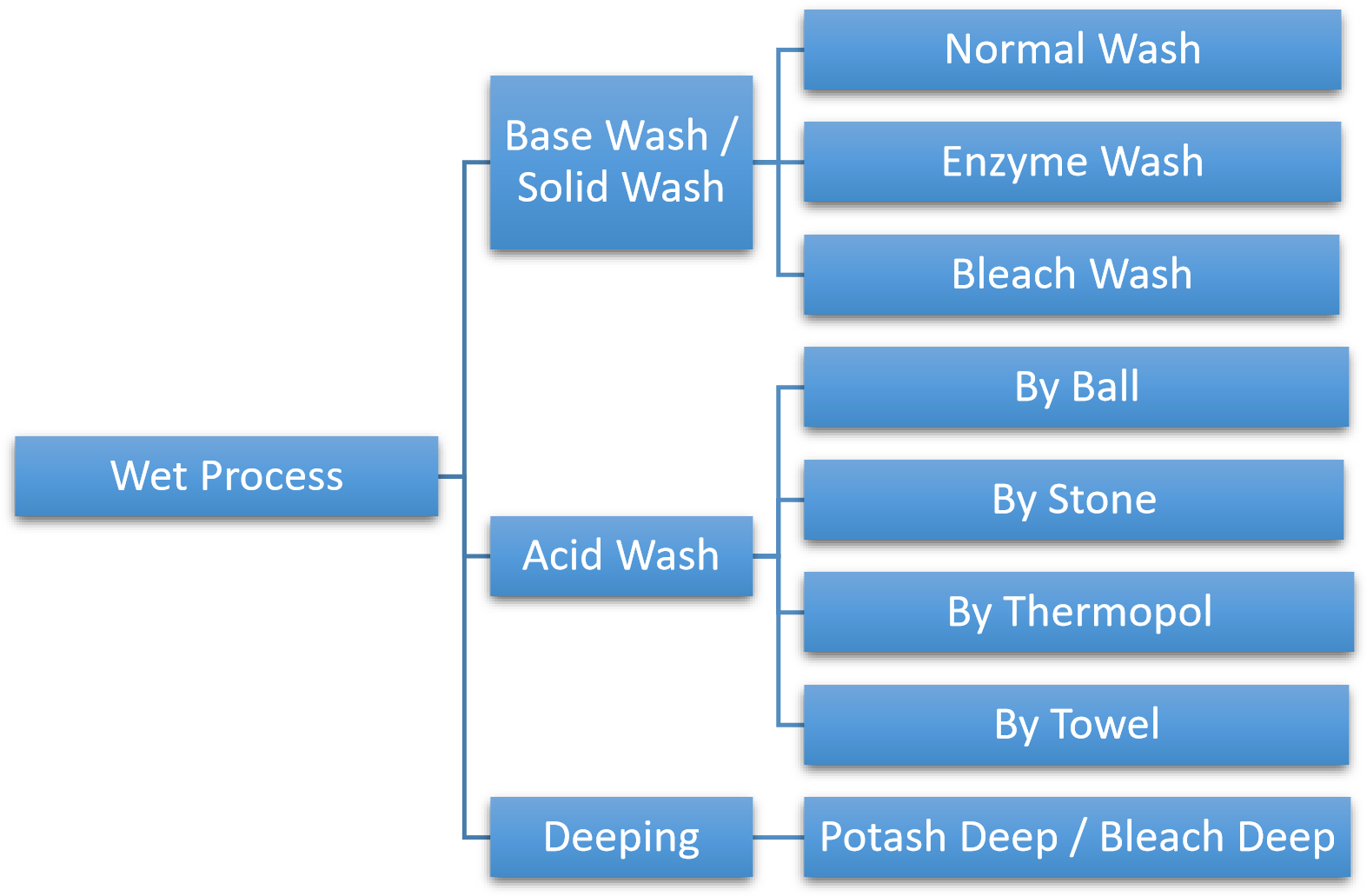

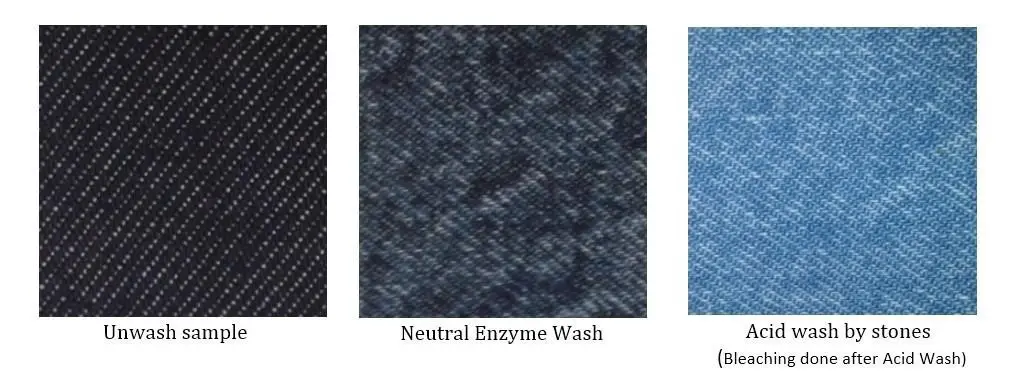

The most popular and fashionable denim garments are random washed in recent days.Due to it’s popularity the demand of this type of washing is increasing day by day. When garments are solid washed the fading effects are even and uniform throughout the garments but when random washed effects are irregular / uneven. Certain amount of treated stones and garments is dry tumbled in the belly washing machine to bring the desired random effects on the garments is called acid washing or snow washing or ice washing,Acid wash is a chemical process which usually strips off the top layer of color from the garments and leaving the white yarns exposed. It gives a overall uneven spotted effect throughout the garments.

Objectives of Acid Wash

- To create irregular fading effects on the garments surface

- To get vintage look

- To fulfill the buyer washing standard

- To increase rubbing fastness

- To improve softness

Acid / Random wash by Balls :

Cotton / Sponge balls are treated with the same solution and soaked properly. The soaking of balls can be done by two ways like loading balls on the machine and spreading the solution on the balls. Then running the machine for 2-3 mins to mix with the solution and wait for another 23 mins to wait for the removal of excess solution from those balls. Another way is to soak those balls in a tub and after removing access solution from those balls loading into the machine. Around 1000-2000 balls are taken for this purpose dependent on the amount of garments to wash. After this wash circular and small line fading effects are found randomly.

Acid / Random wash by Towels :

Same solution used to soak the towels and 100-300 towels are used for this acid wash depending on the garments. It creates big big fading effects on the garments. Towels are soaked and thrown to the belly machine after removing access solution from them. By dry tumbling desired effects are visible on the garments.

Acid / Random wash by Thermopol :

Thermopols are used for knit or soft or light garments washing . Lengthwise fading effects are found in the garments. Thermopols are like foams which are cut into 1 inch or 0.5 inch cubic in structure. Usually 5-10kg thermopols are loaded into the belly machine then solution is spread out through those small thermopols and mix solution by running the machine for 2-3 mins. After getting mixed then garments is loaded into the machine for dry tumbling.

As KMnO4 or NaOCl are hazardous chemicals so neutralization is mandatory for further processing.

Limitation of acid washing

- Due to high abrasion between fabric and stones, heavy fabric is required to create random effect.

- The major cause is residual manganese due to incomplete neutralization, washing or rinsing.

- Indigo dyed denim has a tendency to yellow after random washing.

Disadvantage of stones washing

- Requires more times rinsing and labour to remove the stones dust from finished garments.

- The process may damage the washing machine due to abrasion of stone with machinery parts.

- The process may causes back staining and redeposition

- It may responsible the problem of environmental disposition of waste of the grit produced by the stones.

- Metal buttons and rivets in the garments are required special care during washing otherwise these elements can be damaged.

- Stones turns into powder which brings grayish color in the garments and makes them rough too.

- Stones sometimes abrades the machine which subsequently decreases the quality of product.

- The process is nonselective.

Characteristics of Pumice Stones :

- Found from volcanic explosion

- Light weight so floats on water

- Surface is rough

- Perforated surface

- Origin countries : USA , Indonesia , Turkey , Italy, Philippines etc.

- Turkey stones are white color and Indonesia stones are slightly brown color

- Pumice stones are available in 3 sizes

- Small size: 2-3 cm

- Medium size: 3-5 cm

- Large size: 5-7 cm

Generally 2-3cm pumice stones are mostly used.

- Pumice stones can be used two or three times.

(656)