Blowroom | Basic Functions of Blowroom | Basic Operations in the Blowroom

Blowroom | Basic Functions of Blowroom | Basic Operations in the Blowroom

Introduction

Blow room is the first step of yarn production in spinning mills. A section in which compressed bales are opened, cleaned and blending or mixing to form uniforms lap of specific length is called Blow room section. The cleaning efficiency of blow room is 40 to 70%. This is the first section of spinning line for spinning of cotton yarn.

Functions of blow room

1. Opening the compressed bales of fiber and making the cotton tuft a small size as far as possible.

2. Detecting the metal objects and fire in fiber

3. Cleaning the fiber by removing the dust, dirt, broken seeds etc. and other foreign materials from the fibers.

4. Mixing and blending of different classes or grades of fibers

5. Removing foreign fibers and plastic contaminations

6. Uniform feeding to the next stage.

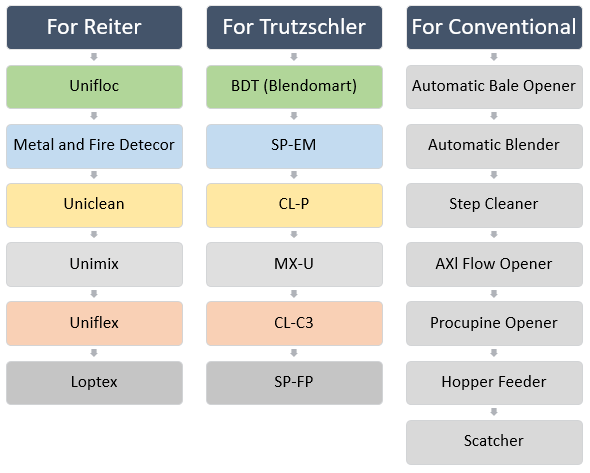

Machines used in a Blow Room Line

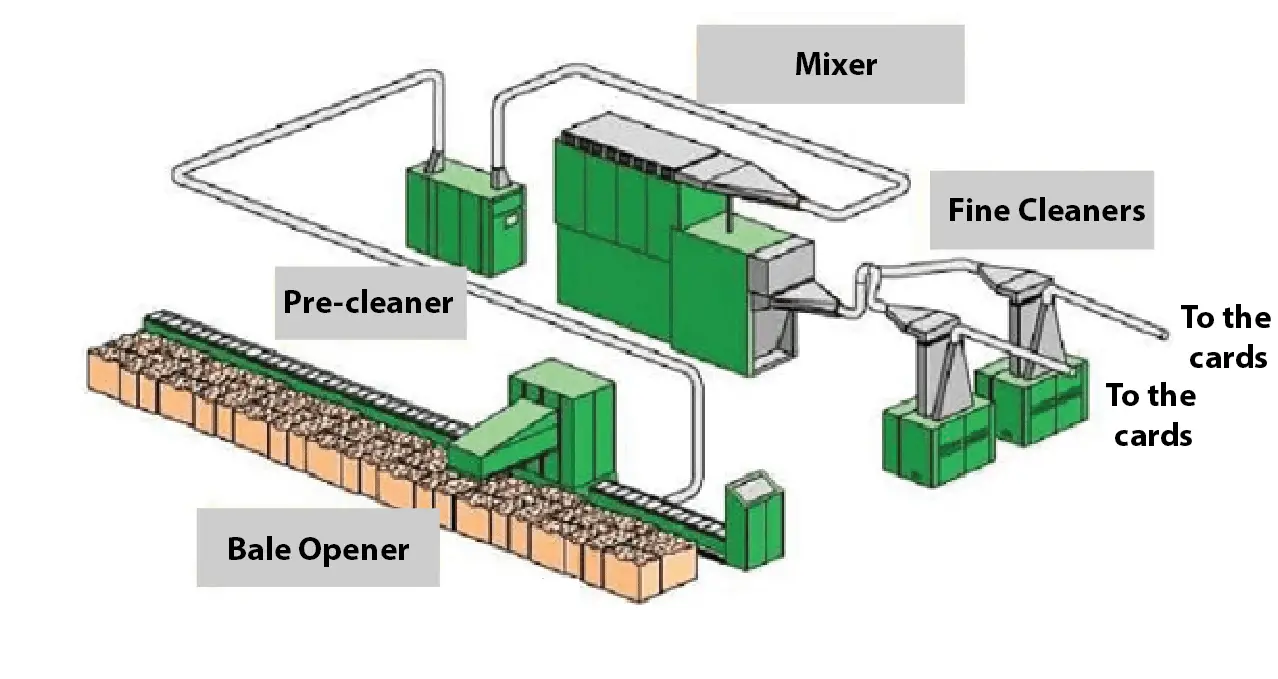

Fig: Blowroom Line for cotton (Rieter)

Fig: Blowroom Line for cotton (Trutzscler)

Principle of Opening and Cleaning

Opening: Opening is the first operation in the blow room carried out to the stage of Flocks. ln the-blow room and to the stage of individual fibers in the cards.

In the stages of the opening, machines with an opening function have the task of separating clumps of fiber into smaller ones. The sizes of the clumps, and of the teeth that deal with them, are progressively reduced. In general terms, grasping clumps of fibers with sets of teeth and dragging the clumps across another set of teeth or grids perform the opening function.

Cleaning: With cotton, there are often seed coat fragments attached to them. It is difficult to remove some of the extraneous matter without vigorous mechanical action and without adequate opening. Every time a clump of fibers is divided, a new surface is exposed from which it is relatively easy to remove the loose unwanted matter (trash).

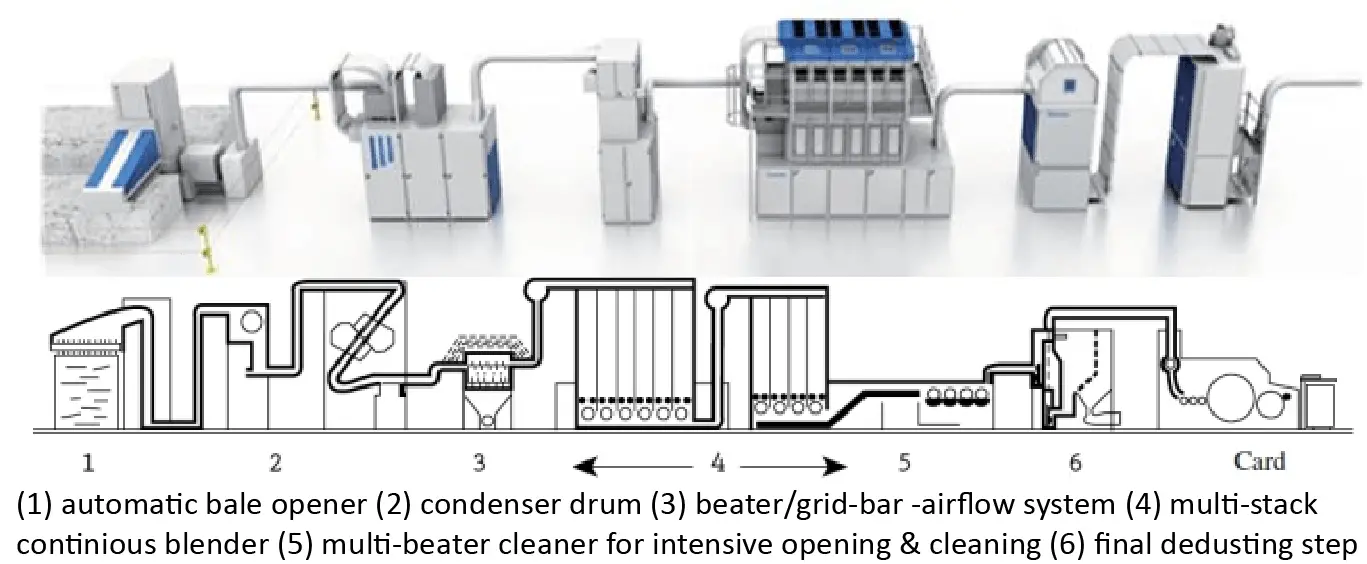

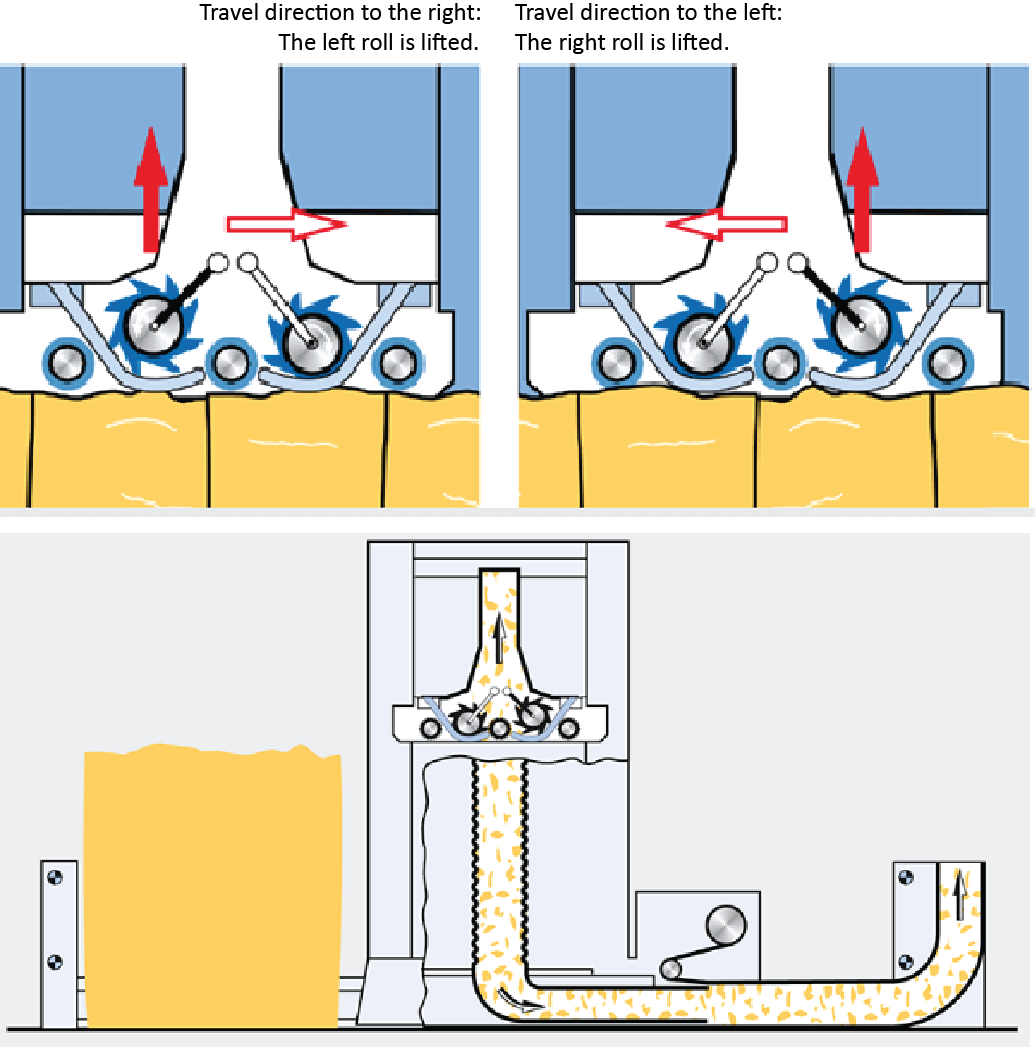

Working Principle of Unifloc/BDT/Automatic Bale Opener

In this zone, basic function is to open the fiber from the bale where fibers are at very compressed and disoriented state. The opening device has to penetrate into the bale and pick up the tuft of fiber during releasing from different bales simultaneously. The size of fiber package is converted from 200 kg to 10 gm/tuft in this zone. The machine moves to cover maximum bales. Generally, roller with toothed disc is used for opening device. No beating action but picking is performed here.

As shown in figure, rotating opening rollers fitted with toothed discs are made to traverse a line of preassembled cotton bales, the toothed discs plucking tufts from each bale as they move from bale to bale. The toothed discs give a gentle opening to prevent or minimize the fiber breakage while producing smaller tuft sizes at higher production rates than the mixing bale opener.

Technical data:

Traverse speed: 10~18 m/min

Speed of take-off roller: 1400~1800 rpm

Nominal take–off depth: 2.5~3.5 mm

Fig: Working element of bale opener or bale breaker (courtesy of Trützschler)

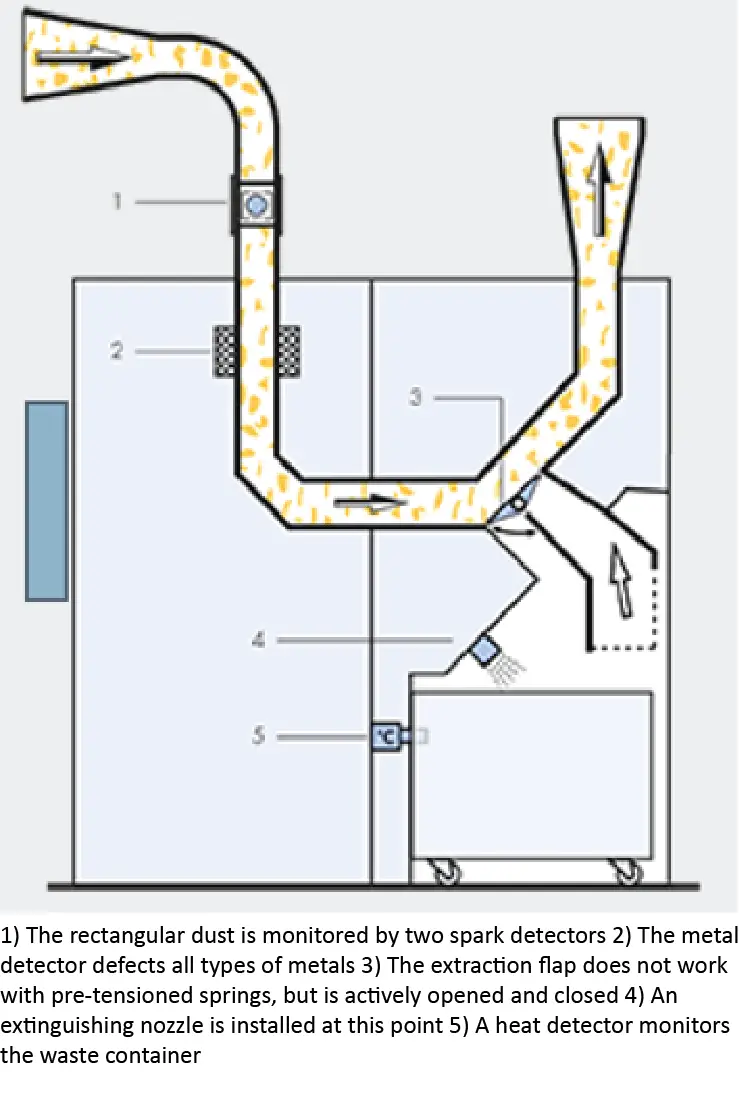

Working Principle of Metal & fire detector/ SP-EM

The electronic Metal Separator SP-EM helps to protect the cleaners and cards from metal parts at the interface between bale work-off and mixers/cleaners. Since, in the process, the material transport is performed by the downstream machine, it is free of exhaust air and requires no filter capacity. In order to reduce fire damage, the machine is equipped with sensors. They are connected to the installation control.

Fig: Electronic Metal Separator SP-EM (courtesy of Trützschler)

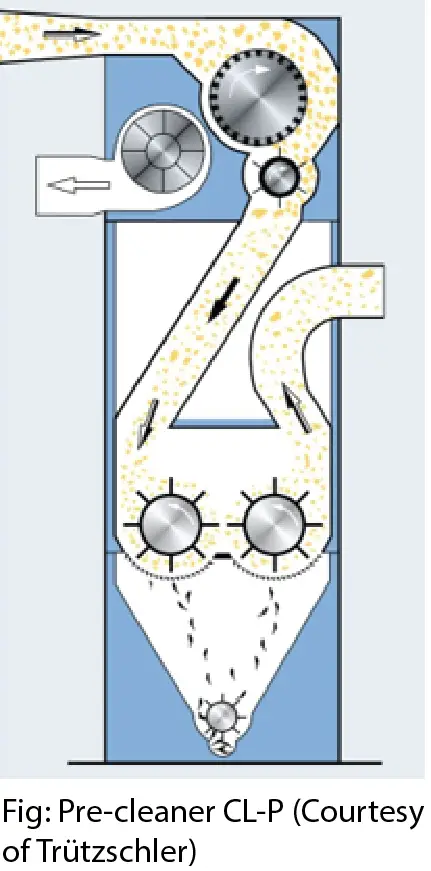

Working Principle of CL-P/Pre-Cleaner

In this zone, basic function is to open the fiber tuft to smaller size and to clean the tuft removing big size of trash but  smaller size of impurities which are trapped between fibers is not removed here. Gentle beating action but no picking is performed here.

smaller size of impurities which are trapped between fibers is not removed here. Gentle beating action but no picking is performed here.

The system comprises two rotating beaters with rods or flexible pins projecting from its surface and a series of grid bars positioned below the beater. The system is used as a first cleaning stage for cotton tufts with high trash content and therefore receives tufts from the automatic bale opener.

The large tufts which cannot get lost through the grid system, follow a spiral path around the beater to the outlet and make contact with the projections (pins) on the rotating beater surface several times. The tufts are then struck against the grid bars to eject coarse trash particles.

Technical data

Diameter of beater: 700~800 mm

Speed of beater: 400~800 rpm

Grid bar setting: 2.5~3.5 mm

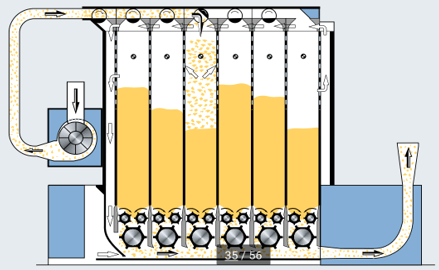

Working Principle of MX-U/Multimixer

In this zone, main function is to blend the raw material of different quality to equalize and even the mean quality of delivered material. Because natural fiber generally remains in variation in quality.

The system employed in this zone as shown in fig. comprises six vertical chambers in sequence. The technology of outlet is implemented in such a way that material is taken up by rotating rollers evenly from every chamber and delivered after mixing. Therefore, mixing takes place homogeneously at the inflow and outflow position.

Technical data:

Storage volume per chamber: 1.4~2.6

Storage capacity per chamber: 40~80 kg

Speed of opening roller: 1000~1200 rpm

Fig: Universal Mixer MX-U (courtesy of Trützschler)

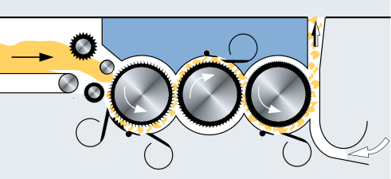

Working Principle of CL-C3

In this zone, basic function is to open the fiber tuft to smallest size and to clean the tuft to the greater extent removing even smallest size of trash and dust which are trapped between fibers.

The system comprises 3 rotating beaters with carding saw tooth wire projecting from its surface with different gradual point density and a series of grid bars positioned below the beater. The system is used as a last opening and cleaning stage for cotton tufts in the blow room and therefore receives tufts from the coarse cleaner and opener.

Importantly, the beater speed should progressively increase from beater 1 to 3 (for example 900, 1100, 1400 rpm). Hence, the mean tuft size is decreased from 1 mg by the first beater to 0.7 mg, 0.5 mg by the second and third beater. Cleaner CL-C3

Fig: Cleaner CL-C3 (courtesy of Trützschler)

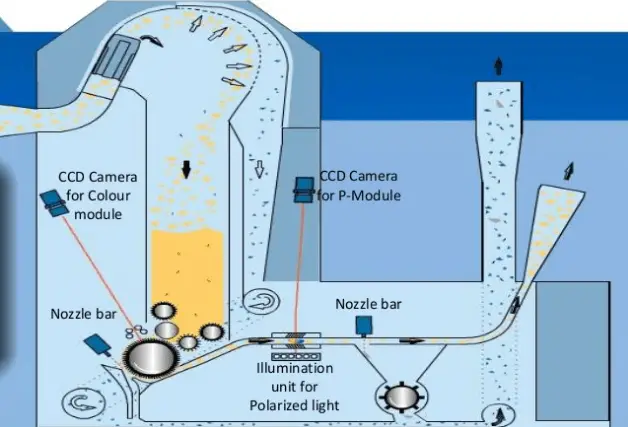

Working Principle of SP-FP

The black arrow indicates the direction of the fiber mass flow as shown in figure. The 3 CCD camera that give high but uniform illumination with two fields. The cameras detect the distorted colors or contrasts generated by the polarization in light polypropylene and transparent or semi-transparent PE foils. On detection of a contaminated part of the fiber mass, a combination of a compressed air nozzle beam and speed sensor are selectively activated to blow the contaminated part of the fiber mass from the fiber channel into a waste suction unit. Therefore, the fiber mass is screened to be free of material contaminants.

Fig: Basic variant SP-FP (courtesy of Trützschler)

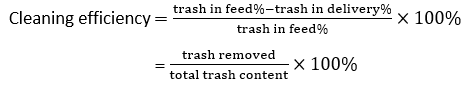

Cleaning Efficiency

Cleaning efficiency of the machine is the ratio of the trash removed by the machine to that of total trash fed to the machine, expressed as percentage.

Let,

Total wt. of fiber in a lay down = 20,000 kg (100 bales)

Trash = 4% of total wt. = 800 kg

Trash removed = 2.8 % of total wt. = 560 kg

So, cleaning efficiency will be 70 % according to the formula.

Basic Parameters to be Considered in Blowroom

- No. of opening machine

- Types of beater

- Beater speed

- Production rate of individual machine

- Fiber micronaire

- Size of the flocks in the feed

- Type of grid and grid setting

- Position of the machine in the sequence

- Amount of trash in the material

- Temperature and relative humidity in the blow room

(16143)