Colour Fastness of Textiles | Colour Fastness to Light

Colour Fastness of Textiles | Colour Fastness to Light

Colour Fastness

The resistance of colour of textiles to fade or bleed against different agencies such as light, wash,water, perspiration, rubbing, acid, alkali,hot pressing, bleaching etc. is called colour fastness.

Colour fastness is a term used in the dyeing of textile materials, meaning resistance of the material’s colour to fading or running. The term is usually used in the context of clothes. The first known use of the word colorfast was in 1916.

Textile Colour Fastness Test standards :

- Society of Dyers and Colourists ( SDC )

- American Association of Textile Chemists and Colorists ( AATCC ).

- International Organisation for Standardisation ( ISO )

- International Wool Textile Organisation ( IWTO ) .

Factors Affecting The Color Fastness Properties :

- The molecular structure (e.g.) of a dye molecule: If the dye molecule is larger in size, it will be tightly entrapped inside the inter-polymer chain space of a fiber. Thus the fastness will be better.

- The manner in which the dye is bonded to the fibre or the physical form present.

- The amount of dye present in the fibre i.e. depth of shade. A deep shade will be less fast than a pale or light shade.

- The chemical nature of the fibre. For example, cellulosic fibres dyed with reactive or vat dyes will show good fastness properties. Protein fibres dyed with acid mordant and reactive dyes will achieve good fastness properties and so on. That is to say compatibility of dye with the fibre is very important.

- The presence of other chemicals in the material.

- The actual conditions prevailing during exposure.

Different Types of Colour Fastness :

- Colour Fastness to Wash

- Colour Fastness to Light

- Colour Fastness to Rubbing / Crocking

- Colour Fastness to Perspiration ( Acid / Alkali )

- Colour Fastness to Saliva

- Colour Fastness to Water ( hot )

- Colour Fastness to Water ( Cold )

- Colour Fastness to Sea Water

- Colour Fastness to Chlorinated Water

- Colour Fastness to Bleaching ( H2O2 / Hypochlorate )

- Colour Fastness to Alkali

- Colour Fastness to Dry Cleaning

- Colour Fastness to Hot Pressing

Assessment of Colour Fastness :

- Changes in the colour of the specimen being tested, that is colour fading

- Staining of undyed material which is in contact with the specimen during the test, that is bleeding of colour.

Instruments for the Assessment of Colour Fastness :

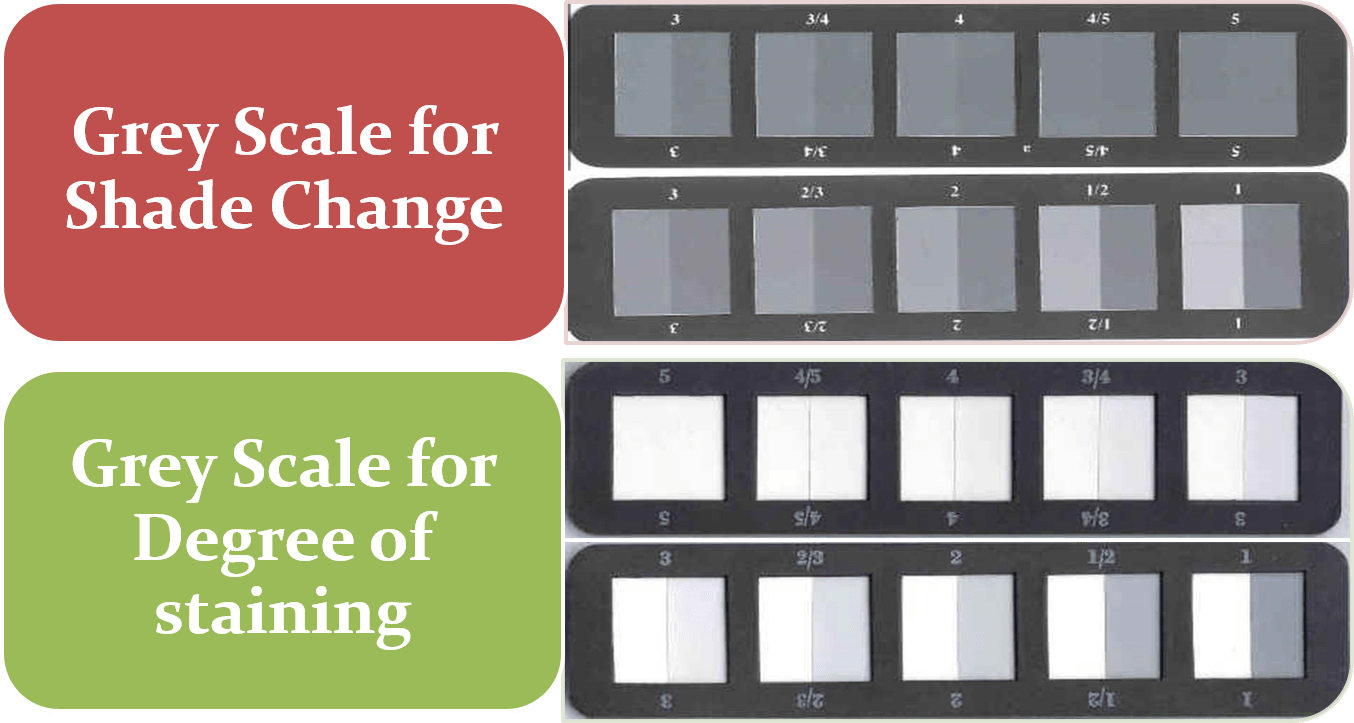

- Visual Assessment ( By Grey Scale )

- Automatic Assessment (By using spectrophotometer )

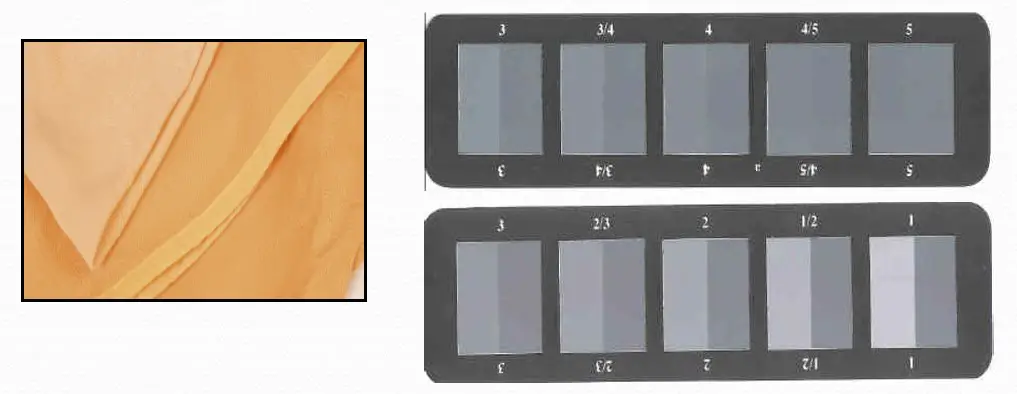

How to assess coloured textiles with grey scale :

With the grey scale, the colour contrast between before test and after test coloured textile is compared with the 09 (nine) pairs of colour contrast in the grey scale.

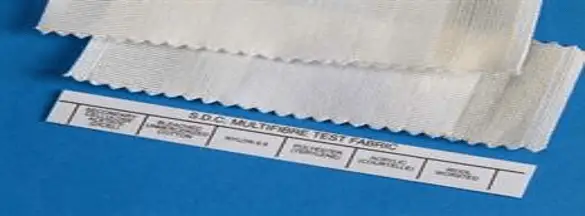

Multifibrea Fabric :

Developed by the Society of Dyers & Colourists in 1986 SDC Multifibre DW is a testing fabric comprising of six different fibre components. SDC Multifibre DW can be used as an adjacent fabric in many of the ISO 105 C Series and E Series of colour fastness tests and meets chain store fastness test specification.

It is produced with a narrow weave construction and contains the following components, secondary cellulose acetate, cotton, acrylic, polyamide, polyester and wool.

Fig : Multifibre Strip

| Multifibre DW | Multifibre TV |

| Secondary Acetate | Triacetate |

| Bleached Cotton | Bleached Cotton |

| Polyamide | Polyamide |

| Polyester | Polyester |

| Acrylic | Acrylic |

| Wool | Viscose |

Grey Scale Rating :

|

Fastness Grade |

Shade Change of Tested Sample |

Colour Fastness of the Sample |

Staining condition of the Sample |

|

Grade-5 |

No Change |

Excellent |

No Staining |

|

Grade-4 |

Slight loss in Depth |

Good |

Very Slight Staining |

|

Grade-3 |

Appreciable loss in depth |

Fair |

Moderate Staining |

|

Grade-2 |

Significant loss in Depth |

poor |

Significant Staining |

|

Grade-1 |

Great Loss in Depth |

Very Poor |

Deep Staining |

(807)