Different types of Sinkers

Different types of Sinkers

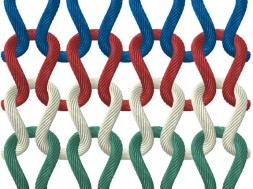

The sinker is the second primary knitting element (the needle being the first).

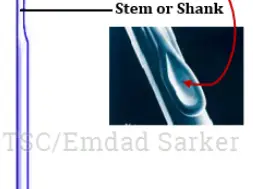

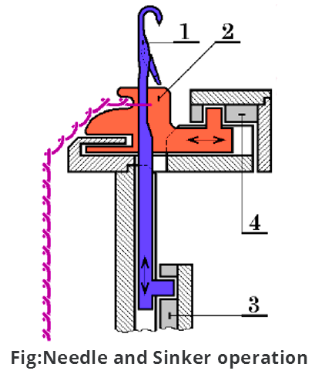

It is a thin metal plate with an individual or a collective action operating approximately at right angles from the hook side of the needle bed, between adjacent needles.

It may perform one or more of the following functions, dependent upon the machine’s knitting action and consequent sinker shape and movement:

- Loop formation

- Holding-down

- Knocking-over

Loop forming sinker

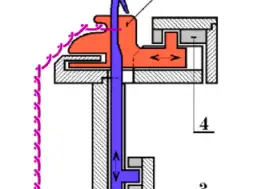

On bearded needle weft knitting machines of the straight bar frame and sinker-wheel type (as on Lee’s hand frame), the main purpose of a sinker is to sink or kink the newly laid yarn into a loop (Figure) as its forward edge or catch (C) advances between the two adjacent needles.

The third function of the sinker – as a knock-over surface – is illustrated in Fig. where its upper surface or belly (B) supports the old loop (O) as the new loop (NL) is drawn through it.

On Tricot warp knitting machines the sinker belly is specially shaped to assist with landing as well as knock-over.

On Raschel warp knitting machines, many V-bed flats, and cylinder and dial circular machines, the verge or upper surface of the trick-plate serves as the knock-over surface.

The second and more common function of sinkers on modern machines is to hold down the old loops at a lower level on the needle stems than the new loops that are being formed, and to prevent the old loops from being lifted as the needles rise to clear them from their hooks.

In Fig., the protruding nib or nose of’ sinker (N) is positioned over the sinker loop of the old loop (O), preventing it from rising with the needle.

On tricot warp knitting machines and single bed weft knitting machines, a slot or throat (T in Fig.) is cut to hold and control the old loop.

Sinker’s operation

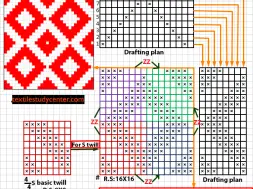

Loop forming sequences

Cam

Cam is the third primary knitting elements which convert the rotary machine drive into a suitable reciprocating action to the needles or other elements. Knitting cams are of three types:

(6018)