Flat Knitting Technology

Flat Knitting Technology

INTRODUCTION :

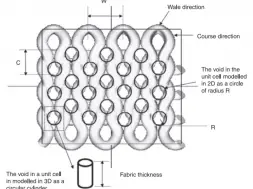

- The fabric which is produced by the machine is usually weft knitted fabric.

- Flat fabric will be produced.

- In the flat knitting machine needles are kept stationary and the cam will move along the width of the machine ( vice versa to circular knitting machine).

- It was first invented in 1865.

TYPES OF MACHINES:

Basically two types

- V-Bed rib machine

- Flat bed purl machine

In a V-Bed machines needle beds are kept diagonally at the angle of 90 to 104 degrees.latch needles are commonly used.

In a flat bed machines both beds are parallel to each other and double hook latch needle will be used.

MACHINE COMPONENTS :

Needle bed:

- The needle bed is a metal plate in which precisely measured slots ( tricks ) are milled.

- The needles are inserted in these tricks and are forced to slide backwards and forwards to form the knitting sequence.

- The distance between the tricks and thickness of the needles determine the thickness of yarn can be processed by the machine.

- There are front and rear bed present in the flat knitting machine.

CAM BOXES :

- To activate the needles and force them to slide up and down in the tricks , the protruding butts are made to follow the cam track.

- The cam track of a manually operated knitting machine have three types of cams

Cam box types :

- Raising cams :

The needle butts are forced upwards on contact with these cams and the needles are driven from their resting position to perform knitting sequence.

- Lowering cams :

These force the needles butts downward to knockover and to form a loops.

- Fixed cams :

These are used to complete the smooth shape of the cam track.

From the above cam structure , the dotted line indicate the needle path which form knit stitch.

How can we introduce miss stitches ?

There is lever connected outside the cam box , the cam ( metal piece) connected to the lever . if we don’t need the cam , simply it will be withdrawn by the lifting of lever.

If withdrawing the raising cam obviously miss stitch will be produced.

How can introduce tuck stitch ?

There is a two type of raising cam present in the cam box . Those were primary raising cam and secondary raising cam. If withdrawing the secondary raising cam all the needles will produce tuck stitch . For producing miss stitch only primary cam will be withdrawn. For producing knit stitch both the primary and secondary cams will be inserted .

How can selectively introduce knit , tuck and miss stitches ?

There is a one more position of cam in between fully inserted and fully withdrawn is partially withdrawn of cam. Using high butt and low butt needle we can selectively introduce knit , tuck and miss stitches.

- If the cam in the fully inserted position , all the high butt and low butt needles will introduce tuck stitches .

- If the cam in the partially inserted position , all the high butt needles will produce knit stitches and all the low butt needles will produce miss stitches.

- If the cam in the fully withdrawn position , all the high and low butt needles will produce miss stitches.

The simple logic is when we withdrawn the cams partially only the high butt needles will follow the cam track. But the low butt needles will miss the cam track.

Conclusion about cam box :

- Only we introduce two stitches simultaneously in the knitting machine . but may be the next course we can change the cam box arrangement.

- Different stitches can be achieved by positioning of cams in the cam boxes ( two beds have separate cam box )

|

Primary cam position |

Secondary cam position |

Results |

|

Fully inserted position |

Fully inserted |

HBN knit , LBN knit |

|

Partially withdrawn |

HBN knit , LBN tuck |

|

|

Fully withdrawn |

HBN Tuck , LBN tuck |

|

|

Partially withdrawn |

Fully inserted |

HBN knit , LBN miss |

|

Partially withdrawn |

HBN knit , LBN miss |

|

|

Fully withdrawn |

HBN tuck , LBD miss |

|

|

Fully withdrawn |

Fully inserted |

HBN & LBN miss |

|

Partially withdrawn |

HBN & LBN miss |

|

|

Fully withdrawn |

HBN & LBN miss |

HBN → High Butt Needles

LBN →Low Butt Needles

Racking of needle bed :

During the process of loop formation , one of the needle beds can be driven sideways a short distance to change the relative position of the needles is called racking . it is measured by needle spaces .

Loop transfer can be achieved by racking of needle bed and then transfer the loop from one needle another needle ( spring loaded needle ).

Is it possible to produce two separate fabrics simultaneously in a flat knitting machine ( V-bed machine ) ?

Yes , we can produce two separate fabrics simultaneously in a V-bed machine . keep one set of needles will be stationary for the two courses using one feeder . then again for the two courses keep another set of needles will be stationary using other different feeder .The design will be like follow picture

Notation of above picture is

For a 5 th and 6 th course one set of needles will knit , at the same time other set of needles will miss the yarn from the first feeder.

For a 7 th and 8 th course one set of needles will miss ( which is knit the yarn previous two courses) and other set of needles will knit ( which is miss the yarn previous two courses) the yarn from the second feeder.

So that four courses will be needed for completing the design of producing two separate fabrics.

The cams should be arranged by the following image :

Is it possible to produce tubular fabric in flat knitting machine ? ( V-bed machine )

Yes , we can produce tubular fabric in the flat knitting machine. The same procedure followed for producing two separate fabrics . The production of tubular fabric using only one feeder will be enough instead of using two feeders in the production of two separate fabrics.

So that two courses will be a repeat of design to produce a tubular fabric .

The design will be like the following image :

For the production of 5 th course one set of needles will knit and other set of needles will miss the yarn from one feeder .

For the production of 6 th course vice versa to previous course from the same feeder

The arrangement of cams for producing tubular fabric will be like the following image :

Where the shaded part will be indicate that cam will be active

The biggest advantage of producing two separate fabrics and tubular fabric:

- We can produce a weft knitted fabric with a knitted pocket . so that no need for stitching a pocket in a knitted fabric.

- We can produce a protective garment ( the body is a separated fabrics and the edges will rib fabric) . we can insert the metallic plate inside the fabric for protection .

Advantages of flat knitting :

- Very suitable for high cost raw material due to the zero percentage wastage.

- Due to the loop transfer , the yarns are not float under the fabric , so that fabric weight will be less.

- Intersia fabric can be easily produce in a flat knitting machine .

- The shifting of wale line can be achieved in the case of flat knitting , so that we can reduce the width of fabric during knitting.

Disadvantages of flat knitting :

- Very high cost of machine.

(4951)