Introduction to Textiles

Introduction to Textiles

What is Textile?

The word ”textile” originally applied only to woven fabrics, now generally applied to fibers, yarns, or fabrics or products made offers, yarns or fabrics. The term textile originates from the latin verb texere to weave but, as the Textile Institute’s Terms and Definitions Glossary explains, it is now ”a general term applied to any manufacture from fibers, filaments or yarns characterized by flexibility, fineness and high ratio of Length to thickness”

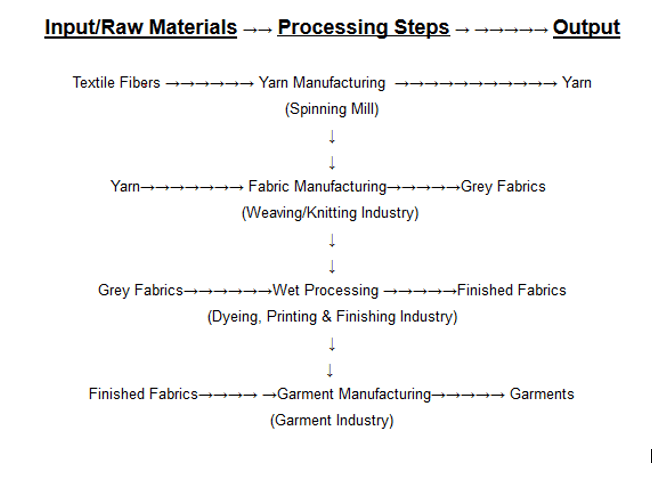

Textiles, especially fabrics the fundamental component of a ready made garment, because it is the basic raw material of a garment. So it is important to know the manufacturing sequence of fabric from fiber. The quality product is the main goal at present time, Without knowledge of Textile manufacturing i.e. fiber, yarn and fabrics it is impossible to maintain the quality of a garment. Before elaborating on whole process of grey fabric manufacturing Let us look on what is textile fiber, yarn and fabric and what are the process flow chart of Textile Manufacturing can be described.

Normally, textile is a woven fabric; now applied generally to any one of the following:

- Staple fibers and filaments suitable for conversion to or use as yarns, or for the preparation of woven, knit, or nonwoven fabrics.

- Yarns made from natural or manufactured fibers.

- Fabrics and other manufactured products made from fibers as defined above and from yarns.

- Garments and other articles fabricated from fibers, yarns, or fabrics when the products retain the characteristic flexibility and drape of the original fabrics.

Textile is a very widly used term which includes:

- All kinds of fibers(e.g: Cotton, Jute, Wool, Polyester, Viscose etc)

- All kinds of Process(e.g: Spinning, Weaving, Knitting, Dyeing, Printing, Finishing etc.)

- All kinds of machineries(e.g: Spinning machineries, Weaving machineries, Knitting machineries, Dyeing machineries, Testing machineries etc.)

- To convert textile fiber into finished or end use products(e.g: Garments, Technical textiles, Geo textiles, Medical textiles, E-textiles etc.)

Flowchart of Textile Processing:

Fiber:

It is defined as one of the delicate, hair portions of the tissues of a plant or animal or other substances that are very small in diameter in relation to there length. A fiber is a material which is several hundred times as long as its thick.

Textile Fiber:

Textile fiber has some characteristics which differ between fiber to Textile fiber. Textile fiber can be spun into a yarn or made into a fabric by various methods including weaving, knitting, braiding, felting, and twisting. The essential requirements for fibers to be spun into yarn include a length of at least 5 millimeters, flexibility, cohesiveness, and sufficient strength. Other important properties include elasticity, fineness, uniformity, durability, and luster.

Banana fiber is one kind of fiber but it is not a textile fiber. Because it can not fill up the above properties. So we can say that all fiber are not textile fiber.

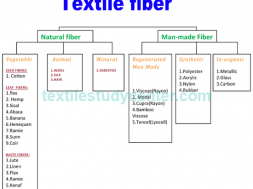

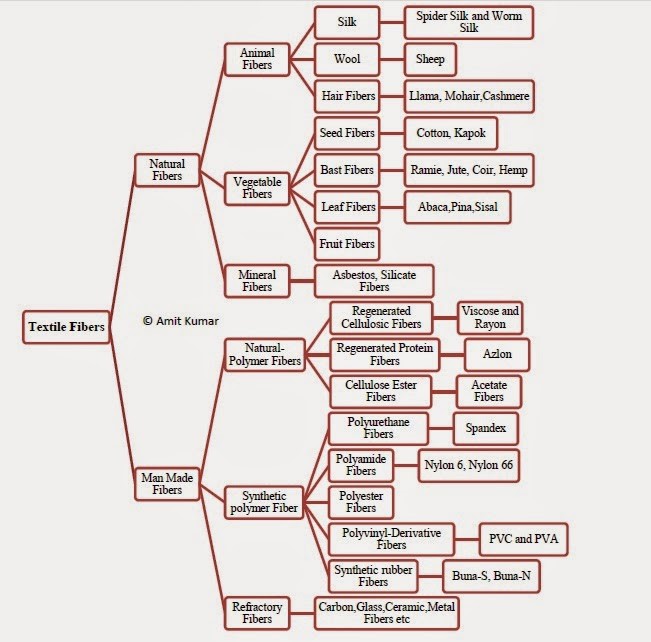

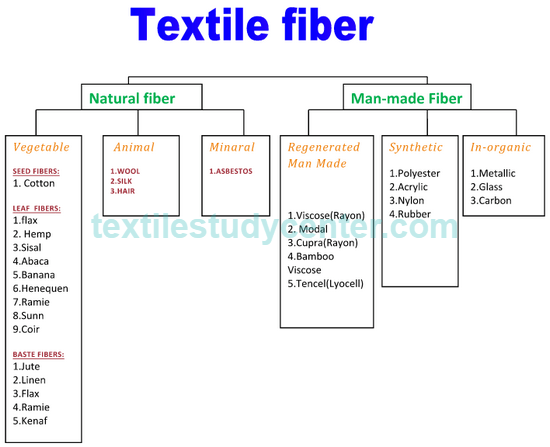

Classification of textile fibers by origin:

I . Natural Fibers:

Natural fibers are fibers that are produced by plants, animals and geological processes.

II . Manmade Fibers:

Man-made fibres are those fibres whose chemical composition,structure, and properties are significantly modified during the manufacturing process

1 . Natural Polymer Fibers: The most common natural polymer fibre is viscose, which is made from the polymer cellulose obtained mostly from farmed trees. Other cellulose-based fibres are Lyocell, Modal, Acetate and Triacetate. Less common natural polymer fibres are made from rubber, alginic acid and regenerated protein.

2 . Synthetic Polymer Fibers: There are very many synthetic fibres i.e. organic fibres based on petrochemicals. The most common are polyester, polyamide (often called nylon), acrylic and modacrylic, polypropylene, the segmented polyurethanes which are elastic fibres known as elastanes (or spandex in the USA), and speciality high-tenacity fibres such as the high performance aramids and UHMwPE (Ultra High Molecular weight PolyEthylene).

3 . In-organic/ Refractory Polymer Fibers: The inorganic man-made fibres are fibres made from materials such as glass, metal, carbon or ceramic. These fibres are very often used to reinforce plastics to form composites.

Difference between Natural Fiber and Manmade Fiber:

|

SL/No |

Natural Fiber |

Man Made Fiber |

|

1 |

The fibers which we get from nature re called natural fiber. |

The fibers which are developed by man re called man made fiber. |

|

2 |

Generally fibers are hydrophilic. |

Generally fibers are hydrophobic |

|

3 |

No. of molecule controlled by nature. |

No. of molecule controlled by man. |

|

4 |

Length of the fiber is nature given. |

Length of the fiber is controlled by man. |

|

5 |

We get fibres as staple or filament. |

No question about short or long staple fiber. It depends on man will. |

|

6 |

Less strength and durability. |

More strength and durability. |

|

7 |

No need to spinneret for spinning process. |

Spinneret is essential for filament production. |

|

8 |

The fabric made from natural fiber is comfortable and good for health. |

Man made fiber is not comfortable and not good for health. |

|

9 |

Natural fiber is not favorable for finishing. |

Manmade fibers are favorable for finishing. |

|

10 |

Comparatively less durable than synthetic fiber. |

Manmade fibers are more durable than natural fiber. |

|

11 |

Fineness varies from one fiber to another fiber. |

Fineness depends on the manufacturers |

|

12 |

Natural fiber has a great demand as humans wear. |

Synthetic fiber is widely used in every day life except humans wear. |

|

13 |

Natural fiber is called environment friendly. |

Manmade fibers are not environment friendly. Some fibers are harmful for the environment like: Polypropylene. |

|

14 |

Natural fibers needs to scouring and bleaching process before wet processing. |

Scouring and bleaching is done in very few cases |

|

15 |

It is not possible to change in fiber structure. |

It is easy to change in fiber structure. |

|

16 |

It is expensive. |

It is cheaper. |

History Of Textile Fibre :

Natural Fibers

Natural fibers have traditionally been used in all cultures of the world to meet basic requirements of clothing, storage, building material, and for items of daily use such as ropes and fishing nets. People in olden times used various kinds of natural fibers depending on their local availability.

The first composite material in history was apparently made with clay and straw in Egypt 3000 years ago to build walls. Hemp was cultivated in China in 2800 BC and is considered one of the oldest natural fibers to be taken in use for making products along with linen. Hemp in Greek and Latin terminology was cannabis that led to the word canvas as hemp was used for making sails of boats. Flax or fine linen was used for burial shrouds of Egyptian pharaohs. Similarly nettle was used for making fishing nets in olden times.

India is rich in plant resources and the use of a variety of natural fibers such as banana, pineapple, sisal, hemp, coconut, palm, grasses etc was widely prevalent in olden times. Their use became limited once cotton acquired the prime status in plant fibers. In cotton production, organic cotton accounts for a very small percentage of total cotton production. Silk, linen and jute are other natural fibers that have continued to enjoy popularity.

Manmade Fibers

The history of man-made fibers is less than a century old; until 1910, there were no synthetic or chemical fibers. Today, by mixing different components, manufacturers can take the basic fibers listed below and make them more waterproof or more absorbent, warmer or cooler, thicker or thinner, stiffer or more supple. Some, like polyester and spandex, combine well with natural fibers, making fabrics that wrinkle less or are more form-fitting.

Properties Of Fibers:

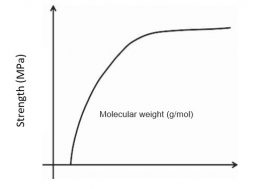

1 . Tensile Strength: This is the breaking strength of any material,which is commonlyexpressed force per unit cross-sectional area. When a single fibre is beingconsidered , the strength of te fibre is commonly described as tanacity.which is measureof spcific stress at breaking point.

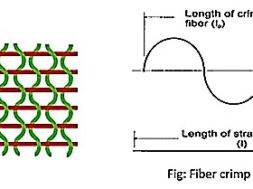

2 . Elongation: When a fibre is subjected to a force, it will stress to a certain degree.This stress is described as elongation.

3 . Elastic Properties: When a fibre is stretched by a small amount ,it may exhibit almost perfect elasticity.That is to say, it will return to its original length when it is realsed.

4 . Specific Gravity: This is a measure of the density of a fibre.it is the ratio of the mass of a materialto the mass of a material to the mass of an equal volume of water at 4 degree C.

5 . Effect Of Moisture: All fibre tend to absorb moisture when in contact with the atmosphere.The amount absorbed depends upon the relative humidity of thr air.In practice, the amount of moisture aborbing properties of afire is described by a figure known as the “Moisture regain”.

6 . Effect Of Sunlight: Almost every fibre i affected by the powerful radiation of sunlight.Some will decompose and deteriorate fairly rapidly, losing strength and changing color.

7 . Effects Of Acids: Textils are commonly subjected to acid solution of one sort or another, and the effect of different acids under varying conditions are important.

8 . Effect Of Alkalies: From the very earliest times, alkaline agents have been used for washing and scouring textiles.

9 . Resistance To Micro-Organisms: Cellulose is attacked by certain moulds and bacteria ,which decompose it and make use of the degradation products as food.

What is Yarn :

A staple-spun yarn is a linear assembly of fibers, held together, usually by the insertion of twist, to a continuous strand, small in cross section but of any specified length; it is used for interlacing in processes such as knitting, weaving, sewing.

What is Nano-fiber:

Nanofibers are fibers with diameters in the nanometer range. It is very fine fibre and it’s count is 0.00001dtex.( tex= mass in gram/1,000m ; dtex=mass in gram/10,000m )

What is Micro-fiber:

Microfiber (or microfibre) is synthetic fiber finer than one denier or decitex/thread, having a diameter of less than ten micrometres. The count of microfiber is 1.0-0.1 dtex.

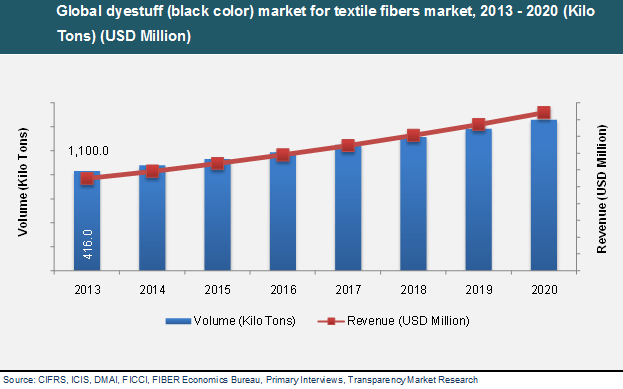

World consumption of textile fibers:

(8544)