Knitted Structures For Sound Absorption

Knitted Structures For Sound Absorption

Introduction :

Textiles have the potential to be used in reducing the interior noise of an automobile as they can provide passive sound absorption in upholstery, headliners and other interior parts. sophisticated technical textiles may well be used to gain a reduction of automotive interior noise. This in turn will make the journey of the occupants more comfortable and may also have a significant impact on the automotive market.

Acoustic Textiles In Vehicles :

Automotive interior noise lies in the acoustic range between 100 and 4000 Hz, although it is more predominant between 100 and 600 Hz; it is undesirable for human living beings. So that acoustic materials used to dampen the noise and may be utilized to reduce noise in the frequencies beyond 600 Hz . As textiles comprise a major part of the automotive interior and provide a low cost environmentally friendly material, it would be prudent to use them for noise reduction wherever possible.

Sound Absorption Of Plain Knitted Structures :

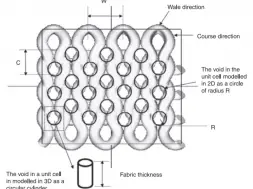

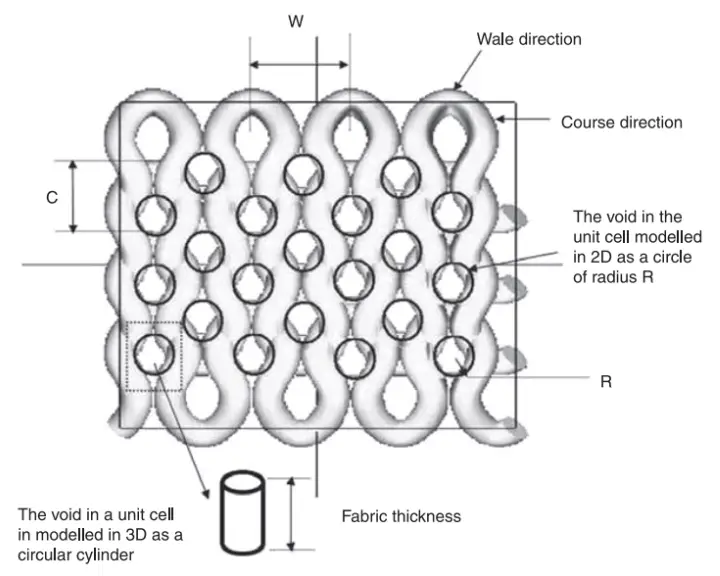

The unit cell of plain knitted structure is the stitch , which is created by intermeshing of yarn loops.

The void space of a unit cell may be approximated as a cylinder of which the circumference is bounded by the yarns forming the loop. As there is a uniform distribution of stitches forming the fabric, there exists a uniform array of circular cylinders in a unit area, whereby a plain knitted fabric can be modelled as a layer with identical cylindrical pores perpendicular to its surface.

Acoustic Impedance And Sound Absorption Of The Plain Knitted Fabric :

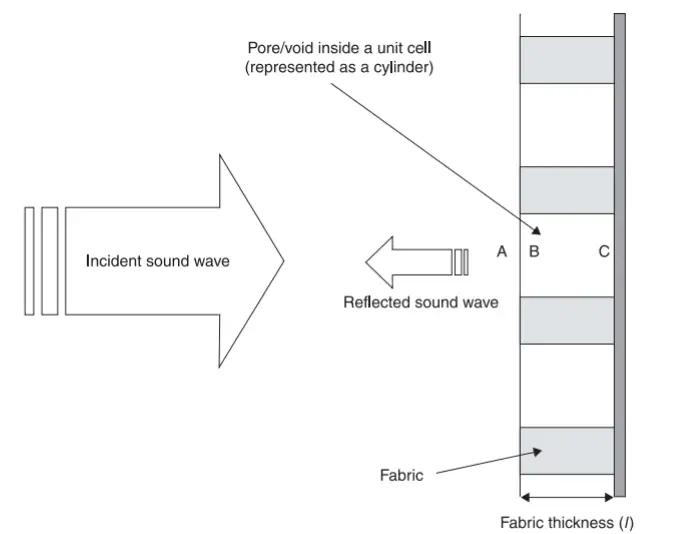

When sound energy in incident normal to the surface,the flow of air is from the surface of the fabric to the pore.

The acoustic impedance at the surface of the fabric at point A is ratio between the acoustic impedance at B and porosity of the material .( porosity is ratio of the air volume to total volume of the material ).

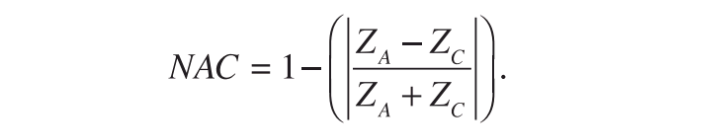

The Noise Absorption Coefficient (NAC) of the fabric can be found by the use of the following relationship ,

ZA is acoustic impedance at the point A

ZC is acoustic impedance at the point C.

The NAC gives the amount of energy from the incident sound wave absorbed by the knitted fabric. To predict the sound absorbed by the knitted fabric, the pore radius of the void formed by the unit cell and the porosity of the fabric must be determined.

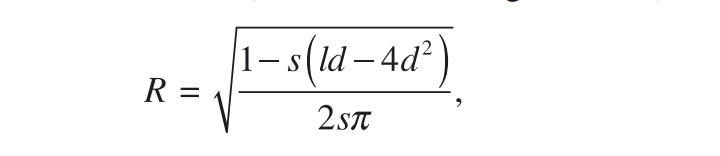

Pore Radius :

R is a pore radius

l is the length of the yarn in one loop (cm)

d is the diameter of the yarn (cm)

s is the stitch density ( number of stitches per square cm)

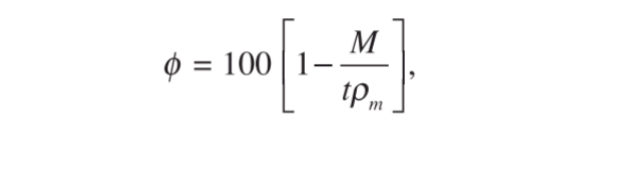

Porosity :

Porosity is defined as ratio of volume of pores within the boundaries of a solid material to total volume . porosity is always expressed as a percentage .

M is the mass per unit area of the fabric

t is the thickness of the fabric

ρ is the density of fibres in the fabric

Engineering Advanced Knitted Fabrics For Sound Absorption :

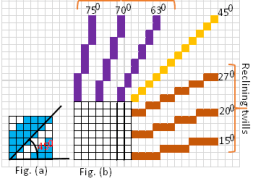

The sound absorption of a single layer of a plain knitted fabric is poor, thus to increase its noise absorption properties the structure has to be made thicker and denser ( that is stitch size must be smaller ) . However, other knitted structures such as rib, interlock, textured and ripple structures will make the fabric thicker and improve the noise absorption at the higher end of the spectrum. Because basic knitted structures alone may not provide sufficient sound absorption for use in automobile interiors, the sound absorbency of two advanced knitted fabrics known as thick spacer and dense spacer structures.

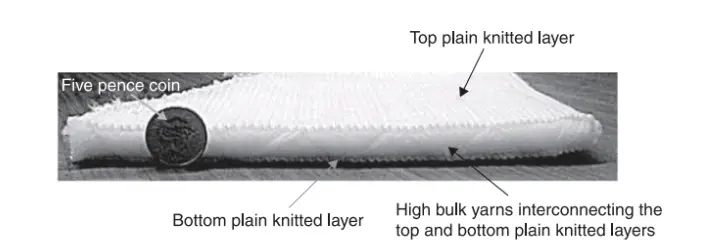

Thick Spacer Structures :

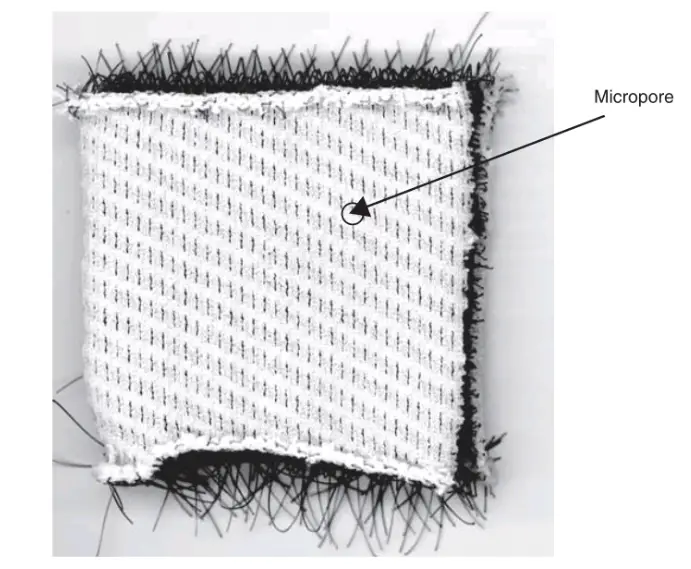

A spacer structure consists of two layers of knitted structure, interconnected but spaced apart by the use of a monofilament yarn. The front and back fabric layers are plain knitted structures knitted using double covered elastomeric yarn. Because of the nylon cover of the inner elastomeric yarn and the elastic nature of the core yarn, the void in a unit cell of a plain knitted structure is essentially closed .

thus, the front and back layers of the spacer may be considered as a fabric sheet, without any pores. However, the locations where the monofilament yarn is tuck looped into the plain knitted layers create a uniform pattern of micropores .

Hence the front and back faces of a spacer structure made of double covered elastomeric yarn can be considered as a fabric sheet with a uniform array of micropores.

Thick spacer structures are lighter and less expensive, and their thickness remains unaltered by moisture and compression, unlike porous sound absorbing materials, including both woven and non-woven structures.

Dense Spacer Structures :

The dense spacer structure consists of top and bottom plain knitted layers. These two layers are interconnected with a mesh of yarn and can be represented as a tight mesh of yarn sandwiched between two plain knitted layers. The interconnecting mesh of yarn is oriented at an angle between the top and bottom layers

Conclusion:

The sound absorbency of these structures increases with both airflow resistivity and thickness. Their porosity is more or less inversely proportional to their airflow resistivity; therefore, their sound absorbency increases with decrease in porosity and increased density. However, the effect of density is more predominant in terms of sound absorbency than thickness. The structures can be made denser by having more rows of the interconnecting yarn between plain knitted courses of the front and back beds.

The structure is a suitable alternative to utilizing several layers of plain knitted fabrics for achieving better sound absorbency, and may be used efficiently in automobile upholstery to reduce interior noise.

The sound absorbency of the dense spacer structure is effective only from 2000 Hz onwards when its Noise Absorption Coefficient (NAC) is greater than 50%.

(929)