Swelling of fibre and Types of swelling

Swelling of fibre and Types of swelling

Swelling

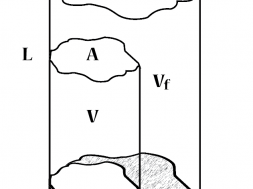

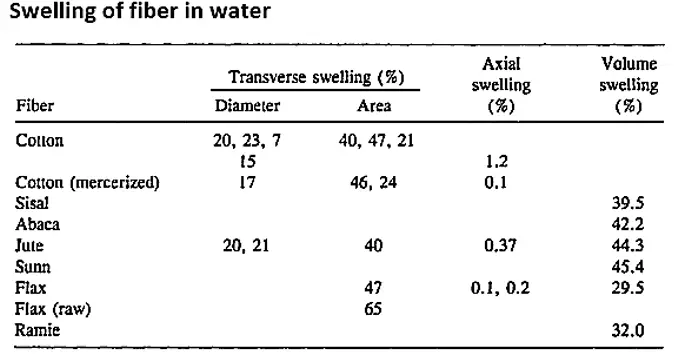

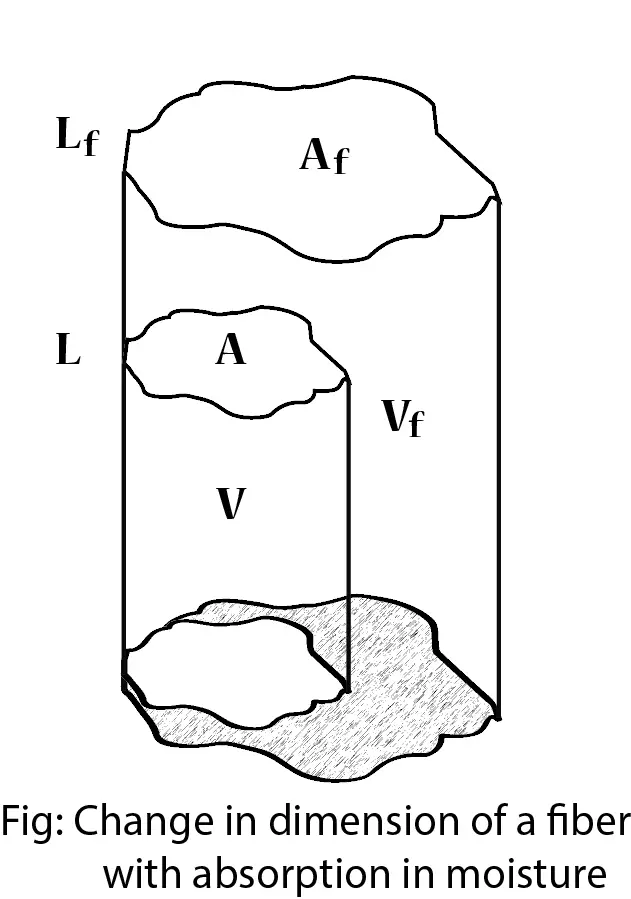

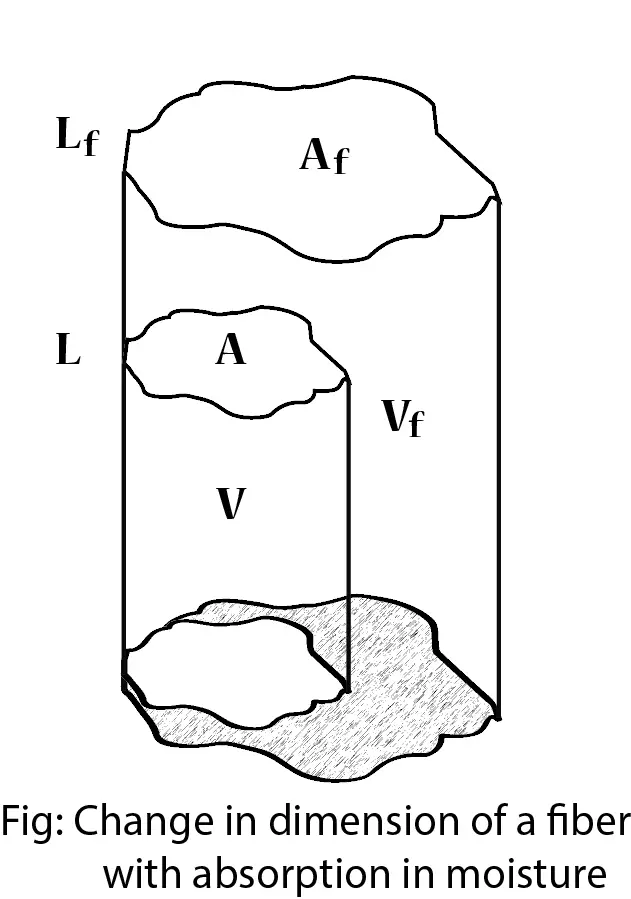

Dimensionally changes due to absorbing water or moisture by any fiber is known as swelling. When fiber absorbs water they change dimensionally. Swelling occurs in transversely (width wise) and axially (Lengthwise). It may be expressed in terms of the increase in diameter, area, length or volume.

Importance of swelling phenomena in textile

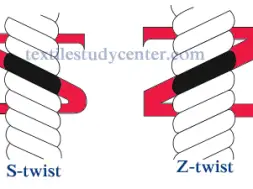

Creep and twist effect: High twisted yarn, which makes more appearance fabric. Due to the swelling twist angle of the yarn is increased. The highly twisted yarn makes more creep effect in the fabric. As a result fabric appearance is increased.

Fabric dimension change/Shrinkage: Due to swelling, dimensional stability of the fabric is increased. As a result fabric shows shrinkage in yarn or cloth.

Water impermeability: Due to swelling, the pores of closely inserted woven fabric will be completely blocked and they may produce water proof fabric.

Different types of swelling

- Transverse diameter swelling

- Transverse area swelling

- Axial swelling

- Volume swelling

1 . Transverse diameter swelling:

Fractional increase in diameter of a fiber after swelling is called transverse diameter swelling. Mathematically,

Where, D = diameter of original fiber

Df = diameter of swollen fiber

∆D = increased diameter after swelling

2 . Transverse area swelling:

Fractional increase in the area of a fiber after swelling is called transverse area swelling. Mathematically,

Where, A = area of original fiber

Af = area of swollen fiber

∆A = increased area after swelling

3 . Axial swelling:

Fractional increase in length of a fiber after swelling is called axial swelling. Mathematically,

Where, L = length of original fiber

Lf = length of swollen fiber

∆L = increased length after swelling

4 . Volume swelling:

Fractional increase in volume of a fiber after swelling is called volume swelling. Mathematically,

Where, V = volume of original fiber,

Vf = of swollen fiber,

∆V = increased volume after swelling

Note: All are expressed by percentage.

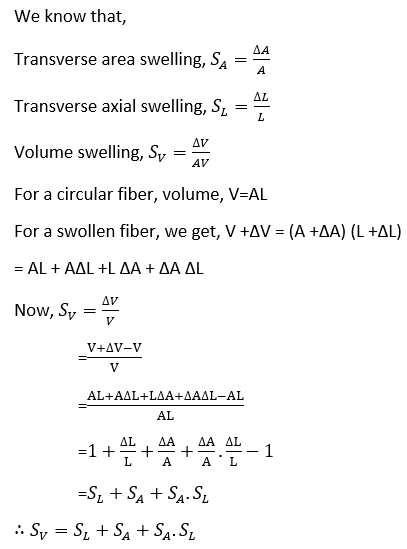

Relation between SA, SL and Sv :

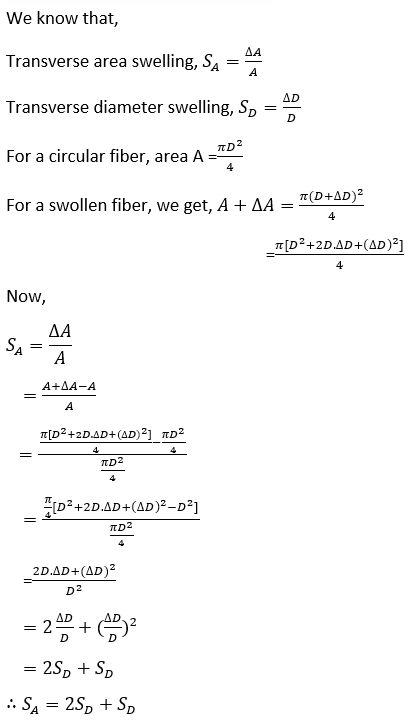

Relation between SA and SD :

Relation between SA and SD :

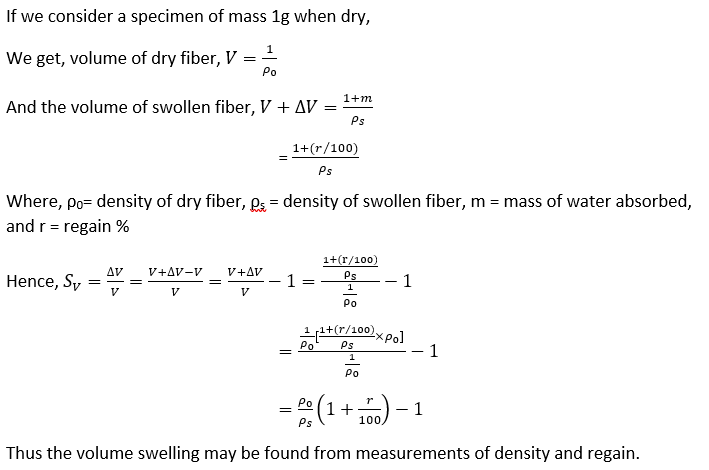

Fiber density and its measurement :

Fiber density is defined as the ratio of fiber mass (m) to fiber volume (V).

ρ=m/v

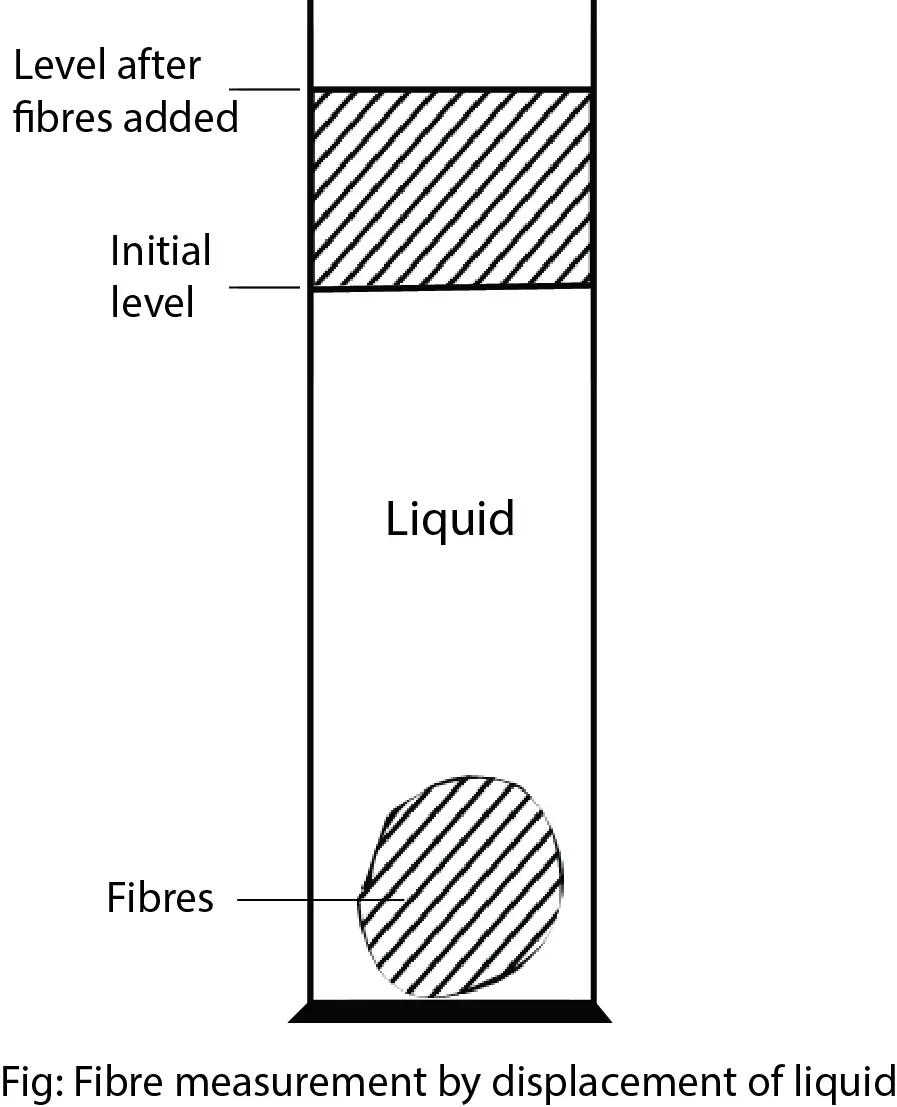

The measurement of fiber mass can be readily obtained by a suitable weighing balance. The task of measuring fiber volume for a given mass by a classical method of displacement of liquid in a measuring cylinder is complicated because of entrapped air and the absorption characteristics of textile fibers.

(2494)